Guía de compra de impresora 3D

Encuentra el 3D perfecto

Impresora para tus proyectos.

¡Comienza tu aventura creativa hoy!

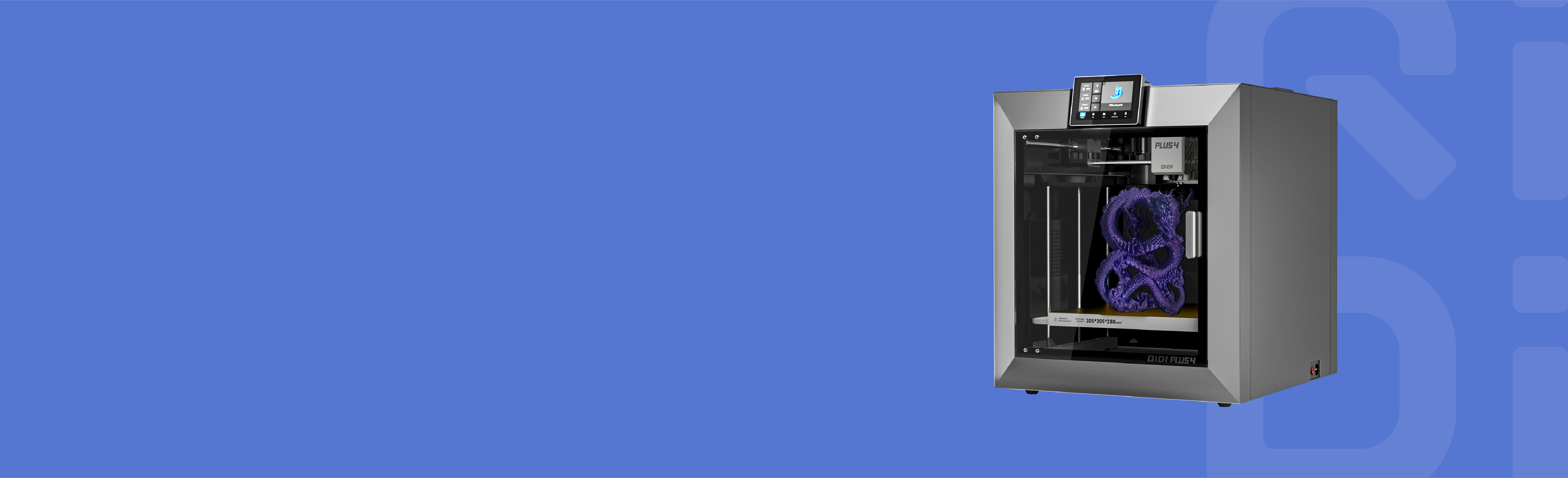

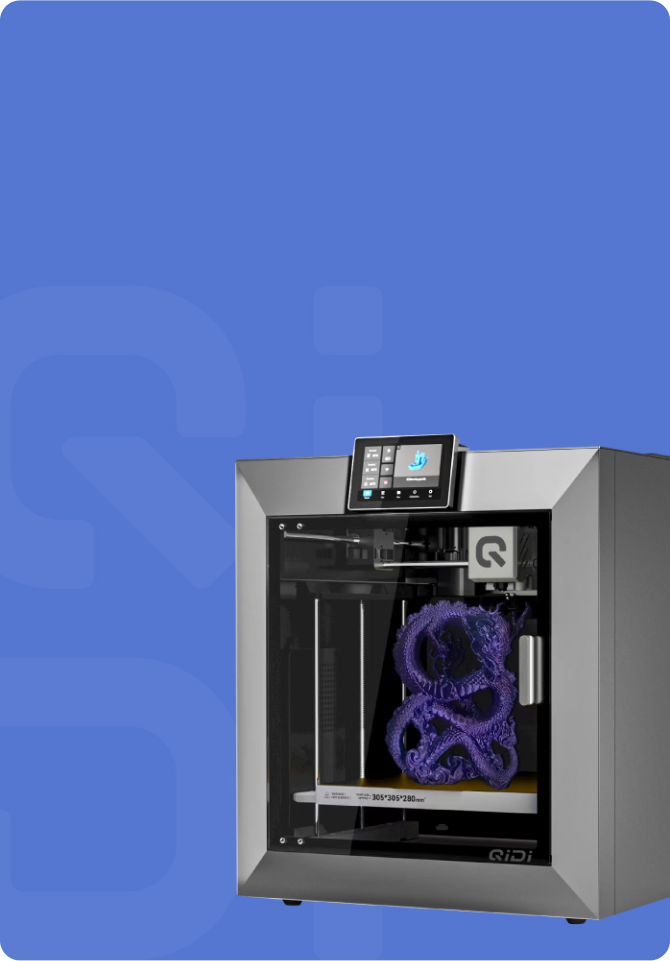

Dale vida a tus ideas con <tc>QIDI</tc> Impresoras 3D FDM

El modelado por deposición fundida (FDM) es una tecnología de impresión 3D predominante en el corazón de

Las impresoras FDM son uno de los tipos de impresoras 3D más populares del mercado actual. Este tipo de impresora 3D ofrece una buena compatibilidad con los materiales y es fácil de usar.

Versatilidad del material: Las impresoras 3D FDM admiten el uso de una variedad de materiales termoplásticos, incluidos PLA, ABS, PETG, TPU, etc. Cada material tiene propiedades únicas, como resistencia, flexibilidad, resistencia al calor y transparencia, y puede elegir el más adecuado. material de impresión 3D según su aplicación específica.

Rentabilidad: En comparación con otros métodos de impresión 3D, la tecnología FDM suele ser más asequible. El coste de las impresoras FDM es relativamente bajo y el precio de las materias primas (filamentos) también es razonable. Esto convierte a la FDM en una opción viable para aficionados, educadores y pequeñas y medianas empresas.

Fácil de usar y mantener: Nuestras impresoras FDM cuentan con un panel de control sencillo y claro que permite a los principiantes controlar fácilmente las funciones básicas de la impresora pulsando botones o girando perillas. El funcionamiento es intuitivo y fácil de entender. El mantenimiento también es sencillo, y consiste principalmente en la limpieza regular, el reemplazo de boquillas y la calibración ocasional.

Las impresoras 3D FDM se utilizan en muchos campos, incluido:

Necesidades diarias: Imprima artículos para el hogar, como soportes para teléfonos móviles, llaveros, posavasos, soportes para frascos de especias y suministros de oficina, como cajas para guardar archivos y alfombrillas para ratón.

Piezas Artísticas y Decorativas: Se utiliza para crear esculturas, incluidas esculturas abstractas y esculturas con temas específicos, y para hacer joyas únicas como aretes y colgantes de collar.

Modelos educativos: Crear modelos de enseñanza, como modelos de órganos humanos en clases de biología, modelos topográficos en clases de geografía y modelos geométricos en clases de matemáticas.

Prototipos industriales & Piezas personalizadas: Imprima prototipos de productos para probar su apariencia y función en las primeras etapas del desarrollo del producto e imprima piezas personalizadas para equipos industriales especiales.

Médico & Aplicaciones sanitarias: Fabricar aparatos ortopédicos personalizados, como almohadillas de soporte de arco y guías quirúrgicas para ayudar en la cirugía oral u ortopédica.

Si no está seguro de qué impresora 3D es adecuada para usted, primero puede aclarar el propósito o el objetivo de la impresión:

Propósito de impresión

Nivel de consumidor (personal/familiar): Adecuado para imprimir modelos pequeños, diseños creativos y, por lo general, con un presupuesto más bajo, como

Nivel profesional (educación/laboratorio): Hay que tener en cuenta tanto la precisión como la estabilidad, lo que permite una impresión de alta velocidad y nivelación automática.

Industrial (producción/fabricación) impresoras como la

Objetivo de impresión

Tamaño del modelo: El nivel industrial requiere un tamaño de construcción grande, mientras que el nivel de consumo es principalmente de 200-300 mm³.

Compatibilidad de materiales: Si necesita imprimir plásticos de ingeniería (abdominales, nailon) o materiales compuestos (reforzados con fibra de carbono), debe elegir un modelo que admita boquillas de alta temperatura y estructura cerrada.

También puede considerar parámetros de rendimiento como la precisión de impresión. Esta se mide por factores como la altura de capa y el diámetro de la boquilla. Alturas de capa y diámetros de boquilla menores generalmente producen impresiones de mayor resolución con detalles más finos. Si su proyecto requiere piezas de alta precisión, busque una impresora que pueda lograr alturas de capa menores y tenga opciones de boquillas más pequeñas.

Preguntas frecuentes

Encuentre respuestas a sus preguntas más apremiantes sobre nuestras máquinas y servicios de impresión 3D.

Una impresora 3D FDM, también conocida como impresoras de modelado de deposición fusionada, es una impresora que crea objetos a través de la deposición de capa por capa del filamento de plástico fundido. El filamento de plástico se calienta hasta que se funde y se extruye a través de una boquilla para formar la forma de interés. Una de las razones por las que las impresoras FDM son populares es que son económicas y muy fáciles de usar, por lo que son ampliamente utilizados por los usuarios principales y profesionales.

Las impresoras 3D FDM tienen varias ventajas. La primera es que generalmente son más rentables que otros tipos de tecnologías de impresión 3D. Esta economía los hace accesibles para un mercado amplio, como aficionados, educadores y profesionales. En segundo lugar, las impresoras FDM son fáciles de usar y acomodan una amplia gama de materiales, desde termoplásticos de grado difícil hasta ingeniería, como ABS y PLA. Estas impresoras son versátiles, lo que permite usarlas en una amplia gama de aplicaciones, desde la creación de prototipos hasta el diseño de piezas funcionales. Las piezas producidas son fuertes y pueden soportar el uso mecánico. Los costos de funcionamiento también son bajos, ya que no requiere ningún tipo de productos químicos peligrosos, lo que hace que sea seguro y fácil de manejar.

El proceso de impresión 3D FDM implica el diseño de un modelo 3D utilizando el software CAD. Después de que su diseño esté listo, el software de corte se utiliza para convertir el modelo en varias capas. La impresora luego calienta el filamento de plástico y lo extruye a través de una boquilla, colocando cada capa de acuerdo con el modelo en rodajas. A medida que se coloca la capa, se enfría y se solidifica, acumulando el objeto final. Este mecanismo de capa por capa proporciona control sobre la forma y la estructura del objeto final.

SLA y FDM son dos tecnologías de impresión 3D diferentes. La principal diferencia es el material y el proceso. Las impresoras FDM usan filamentos termoplásticos, que se derriten y se extruyen para colocar capas. Las impresoras SLA usan resina líquida que se cura por un láser para curar cada capa. SLA generalmente está en una mejor resolución, y las superficies son más suaves, por lo que es muy adecuado para los diseños con muchos detalles y muy intrincados. FDM es más adecuado para prototipos funcionales y piezas más grandes porque es más fuerte y más barato. En general, FDM también es más barato en comparación con las impresoras SLA y sus materiales.

Resolución de impresión, altura de la capa, temperatura de extrusora y plataforma, velocidad de impresión, calidad de filamento, tamaño de boquilla y configuraciones de rebanadores adecuadas afectan la calidad de impresión final. La extrusión dual, una cámara de construcción cerrada y las características de calibración automática también ayudan a mejorar la consistencia, la precisión y la confiabilidad.

Q2

Q2