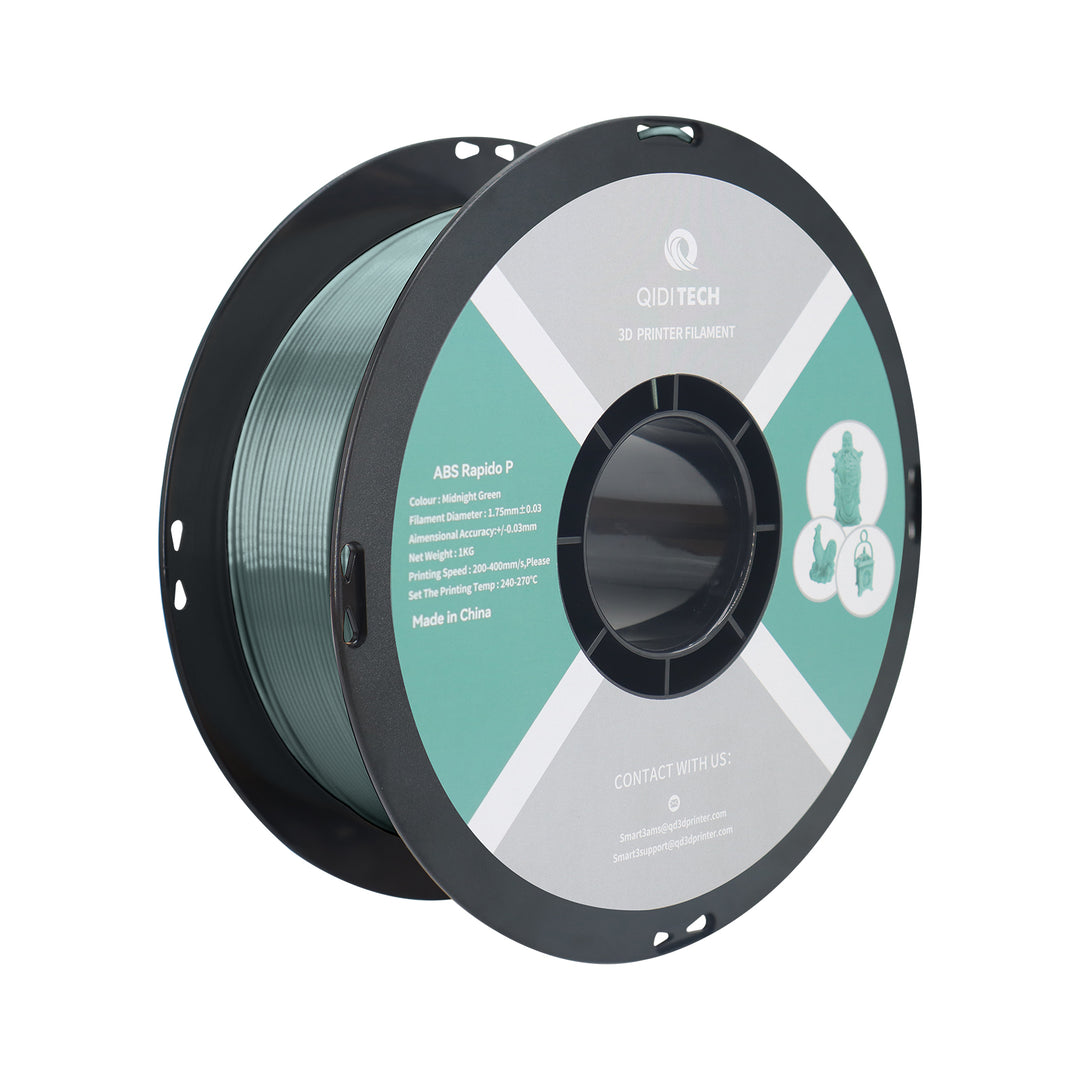

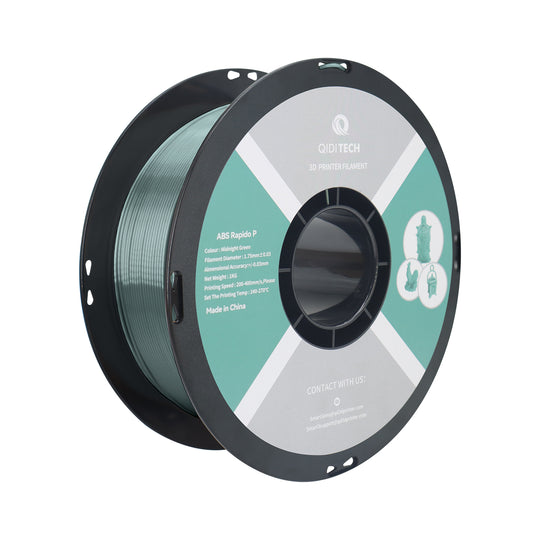

QIDI ABS Rapido Metal 3D Printer Filament

QIDI TECH ABS Rapido Metal Filament is a great choice for functional parts that require durability and decorative qualities. The no-paint metallic texture greatly enhances the texture and quality of the product.

QIDI ABS Rapido Metal Filament Model display

Product Size

QIDI ABS Rapido Metal filament 1.75mm. Works perfectly with most FDM 3Dprinters on the market.

Accessory Compatibility

| Recommended | Not Recommended | |

| Multi-color printing system | QIDI BOX | / |

| Spport Filament | S-white | / |

| Build Plate | QIDI Cool Plate pro, QIDI PEI Plate, HF Plate, Smooth PEI Plate, HF Plate, PC Plate | / |

| Hotend |

Hardened Steel Nozzle ( 0.4 / 0.6 / 0.8 mm) Bimetal Nozzle ( 0.4 / 0.6 / 0.8 mm) Tungsten Carbide Bimetal Nozzle( 0.4 / 0.6 / 0.8 mm) |

Brass/Copper plated Nozzle (0.2/0.4/0.6/0.8 mm) |

| Glue | Glue Stick / 3D LAC adhesive spray | / |

| Recommended Printing Settings | |

| Drying Settings (Blast Drying Oven) | 60 °C,4-6 h |

| Printing and Keeping Container's Humidity | < 15% RH (Sealed, with Desiccant) |

| Nozzle Temperature | 220-250 °C |

| Bed Temperature (with Glue) | 80~100 °C |

| Printing Speed | 40-200 mm/s |

| Physical Properties | |

| Density | 1.05~1.07 g/cm³ |

| Vicat Softening Temperature | 91 °C |

| Heat Deflection Temperature | 75 °C |

| Melting Temperature | 190 °C |

| Melt flow rate | 30~40 g/10 min |

| Mechanical Properties | |

| Tensile Strength | 34~37 MPa |

| Breaking Elongation Rate | 2%~4% |

| Emodulus | 3400~4000 MPa |

| Impact Strength | 22~28 kJ/m² |

Printing Tips

1. ABS Metal is prone to moisture absorption, so it should be stored in a dry environment to prevent moisture from causing bubbles or surface defects during printing.

2.Rapid cooling can lead to cracks or uneven gloss on the surface of ABS Metal, so it is recommended to reduce the use of cooling fans during the printing process to avoid these issues.

For more details please refer to: Filament Guide on WIKI.

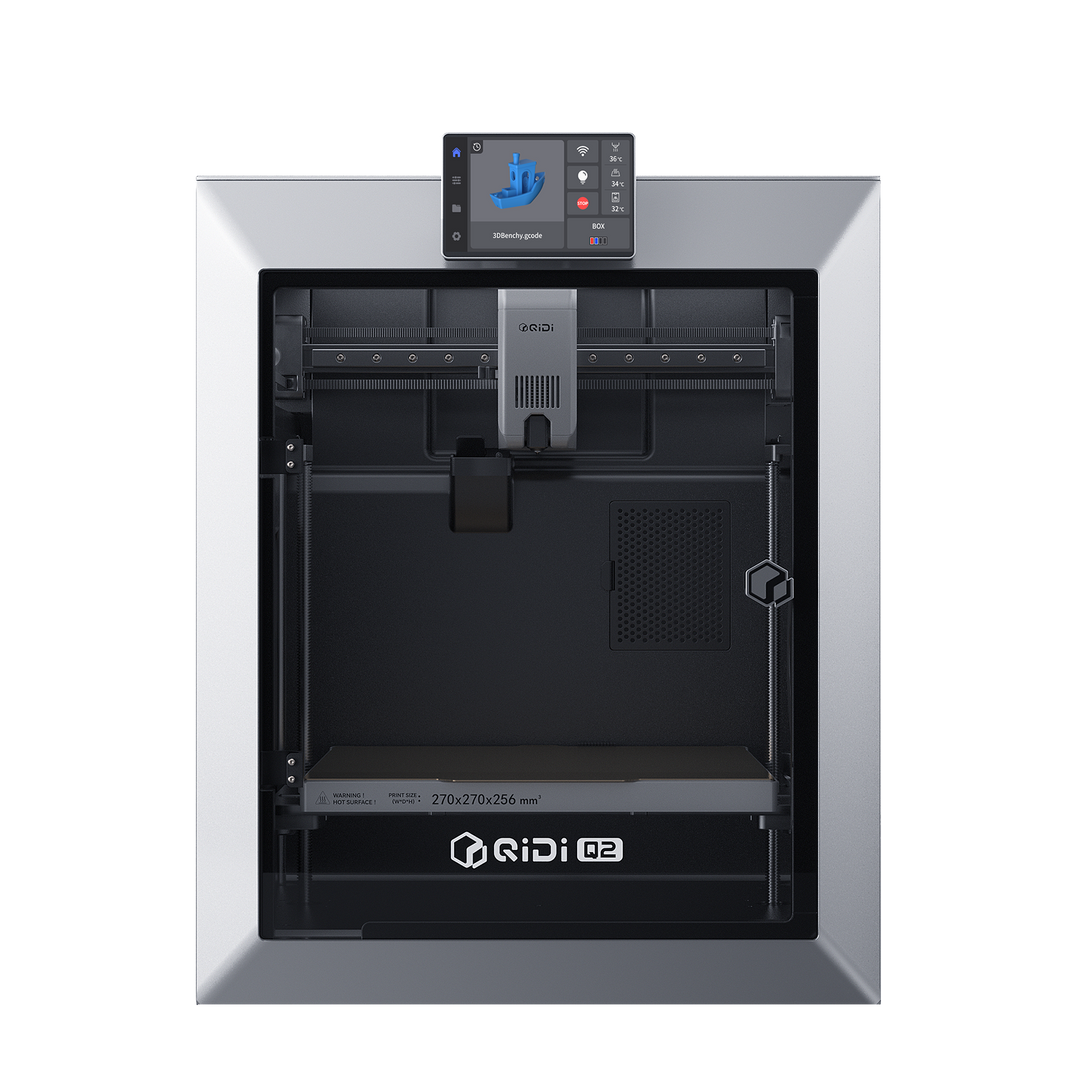

Q2

Q2

QIDI Box

QIDI Box

Plus 4

Plus 4

Q1 Pro

Q1 Pro

X-Max 3

X-Max 3