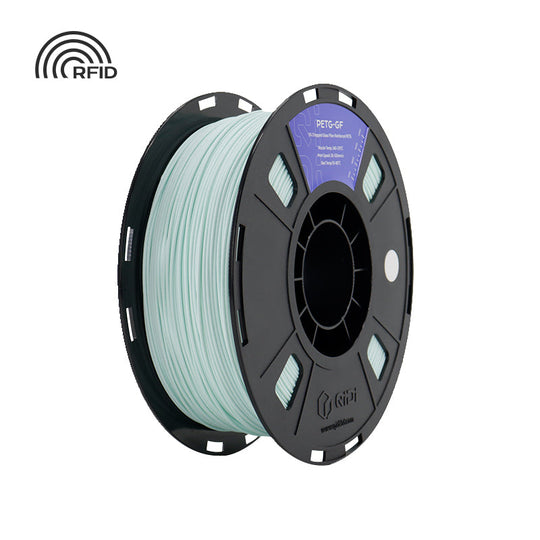

QIDI PETG-GF

QIDI PETG-GF, compounded with 5% short-cut glass fibers, combines the user-friendly properties of standard PETG with the enhanced structural strength and rigidity provided by the glass fibers. This results in improved accuracy and dimensional consistency, along with significantly increased tensile strength and stiffness.

Enhanced Mechanical Properties and Chemical Resistance

Delivers superior strength, rigidity, and impact resistance compared to standard PETG filaments, ensuring long-lasting durability under mechanical stress.

Exhibits strong tolerance to common solvents (e.g., alcohols, soap solutions), making it well-suited for everyday applications and household environments.

Textured Matte Finish and Enhanced Dimensional Stability

Glass fibers provide a matte finish that hides layer lines and improves stability for large prints.

Inherently Non-Conductive

Provides electrical insulation, making it an ideal material for electronic components, protective enclosures, and fixtures where electrical safety is critical.

Outstanding Low-Temperature Resistance

Maintains structural integrity and mechanical performance in cold environments, preventing embrittlement and ensuring dependable operation in outdoor, automotive, or refrigeration applications.

Multifunctional application scenarios

PETG-GF is suitable for a variety of applications from functional indoor parts and creative prototypes to outdoor models, thanks to its high strength, rigidity, dimensional stability, and weather resistance.

Equipped with RFID chip

Equipped with RFID chip, parameters are automatically identified, saying goodbye to manual settings.

Printing Tips

- Pre-printing Drying: PETG-GF is highly hygroscopic.Moist filament may cause stringing and reduced strength during printing.It is recommended to dry at 65°C for 5-8 hours.For extended prints, using a dry box or continuous drying during printing is advised.

- Nozzle Recommendation: The glass fiber content is highly abrasive and can quickly wear down standard brass nozzles, leading to nozzle enlargement and extrusion inaccuracies.A hardened steel nozzle or harder is recommended.

📚For more details please refer to: Filament Guide on WIKI.

Vacuum Aluminum Foil Packaging

According to the test, the water vapor transmission rate of ordinary sealed packaging is 4.76%, while the water vapor transmission rate of vacuum aluminum foil packaging we use is only 0.014%. It can be seen that vacuum aluminum foil packaging is more water-resistant.

Product Size

QIDI TECH PETG-GF Filament 1.75mm Works perfectly with most FDM 3Dprinters on the market.

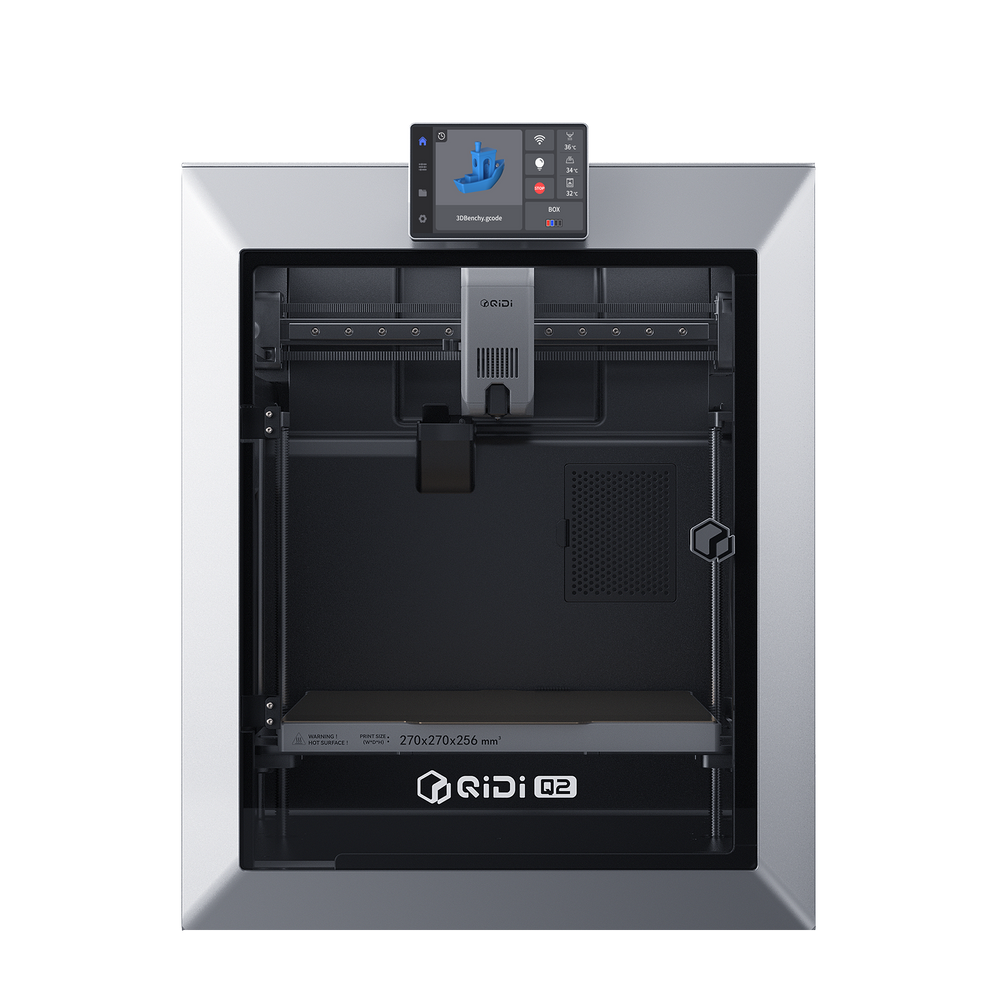

Q2

Q2

QIDI Box

QIDI Box

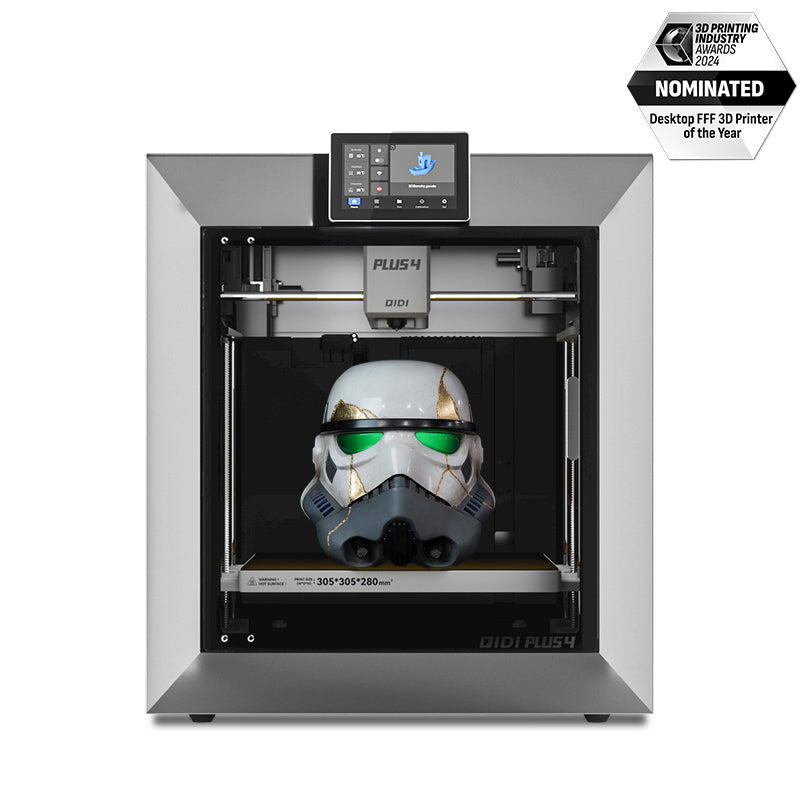

Plus 4

Plus 4

Q1 Pro

Q1 Pro

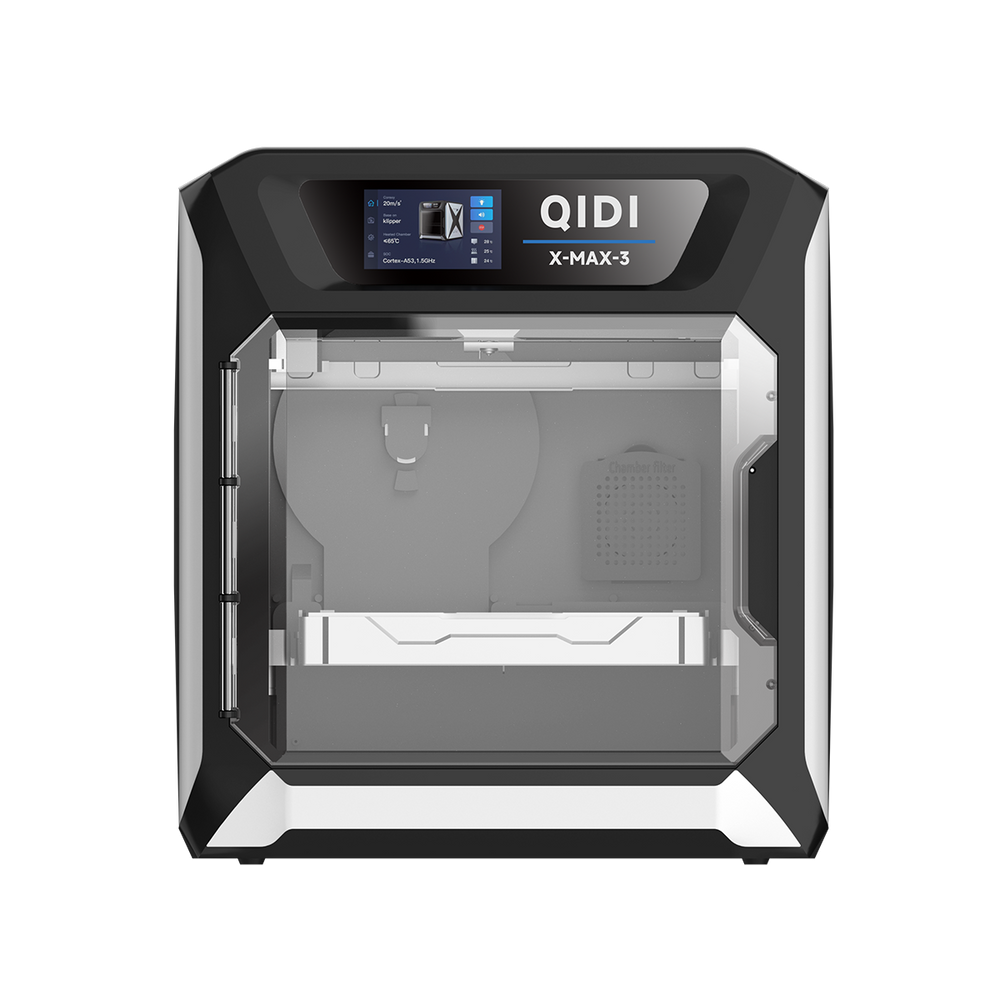

X-Max 3

X-Max 3