QIDI PPS-GF20

Born to tackle the most demanding engineering challenges. PPS-GF20, combining exceptional heat resistance, outstanding dimensional stability, and top-tier electrical insulation properties, is your ultimate choice for achieving innovation and reliability in electronics, aerospace, automotive manufacturing, and high-end industrial applications.

Flame-retardant and chemically resistant

UL94 V0 certified at a thickness of 1.5mm, resistant to acids, alkalis, oils, and solvents.

Excellent Insulation Performance

Boasting a high dielectric strength of 6.1 kV/mm and a low dielectric constant (2.7 @ 1MHz), it provides a solid protective barrier for applications such as 5G base station components, ADAS sensor housings, and electrical insulators.

Exceptional High-Temperature Resistance

Maintains excellent structural strength and shape even in extreme environments up to 240°C (Heat Deflection Temperature).

High Strength and Rigidity

Filled with 20% glass fiber, it reduces material shrinkage while providing printed parts with strength and rigidity (Young's modulus up to 4600 MPa, XY flexural strength up to 105 MPa). Especially suitable for brackets, antenna bases, chemical contact parts, and other components with stringent requirements for strength and stiffness.

Precision, Reliability, and Easy Printing

Supports high-speed printing . Extremely low shrinkage and excellent dimensional stability ensure printed parts maintain precise dimensions from the first layer to the last, enabling easy creation of tightly fitting assemblies and high-precision gear sets.

Ultra-Low Water Absorption

PPS-GF exhibits an extremely low moisture absorption rate of just 0.05%, maintaining stable mechanical and thermal properties even in humid environments. This makes it an ideal choice for high-moisture resistance applications.

Equipped with RFID chip

Equipped with RFID chip, parameters are automatically identified, saying goodbye to manual settings.

Printing Tips

-

Equipment Requirements: The hot end operating temperature must be set between 310°C and 350°C . Higher temperatures result in greater filament strength, but print quality will decrease with increasing temperature.

Hardened steel or higher-grade nozzles are recommended to withstand fiberglass abrasion. -

Material Handling: Ensure the filament is thoroughly dried before printing to prevent print failure.

To prevent moisture absorption, use a sealed storage container with a desiccant during printing.

When not in use, the material must be sealed and stored in a dry environment. -

Post-Processing: Annealing the printed parts can significantly improve their mechanical properties and thermal stability. However, some prints may warp or deform, especially larger or thinner prints.

Recommended annealing conditions: 130°C for 10 hours. - QIDI BOX Usage Tips: Since this filament uses a cardboard spool, it is recommended to use a spool adapter (ABS Filament is recommended) on the cardboard spool when printing this filament with QIDI BOX to prevent the spool from being unable to rotate during material ejection.

📚For more details please refer to: Engineering Filament Guide on WIKI.

Vacuum Aluminum Foil Packaging

According to the test, the water vapor transmission rate of ordinary sealed packaging is 4.76%, while the water vapor transmission rate of vacuum aluminum foil packaging we use is only 0.014%. It can be seen that vacuum aluminum foil packaging is more water-resistant.

Product Size

QIDI TECH PPS-GF20 Filament 1.75mm Works perfectly with most FDM 3Dprinters on the market.

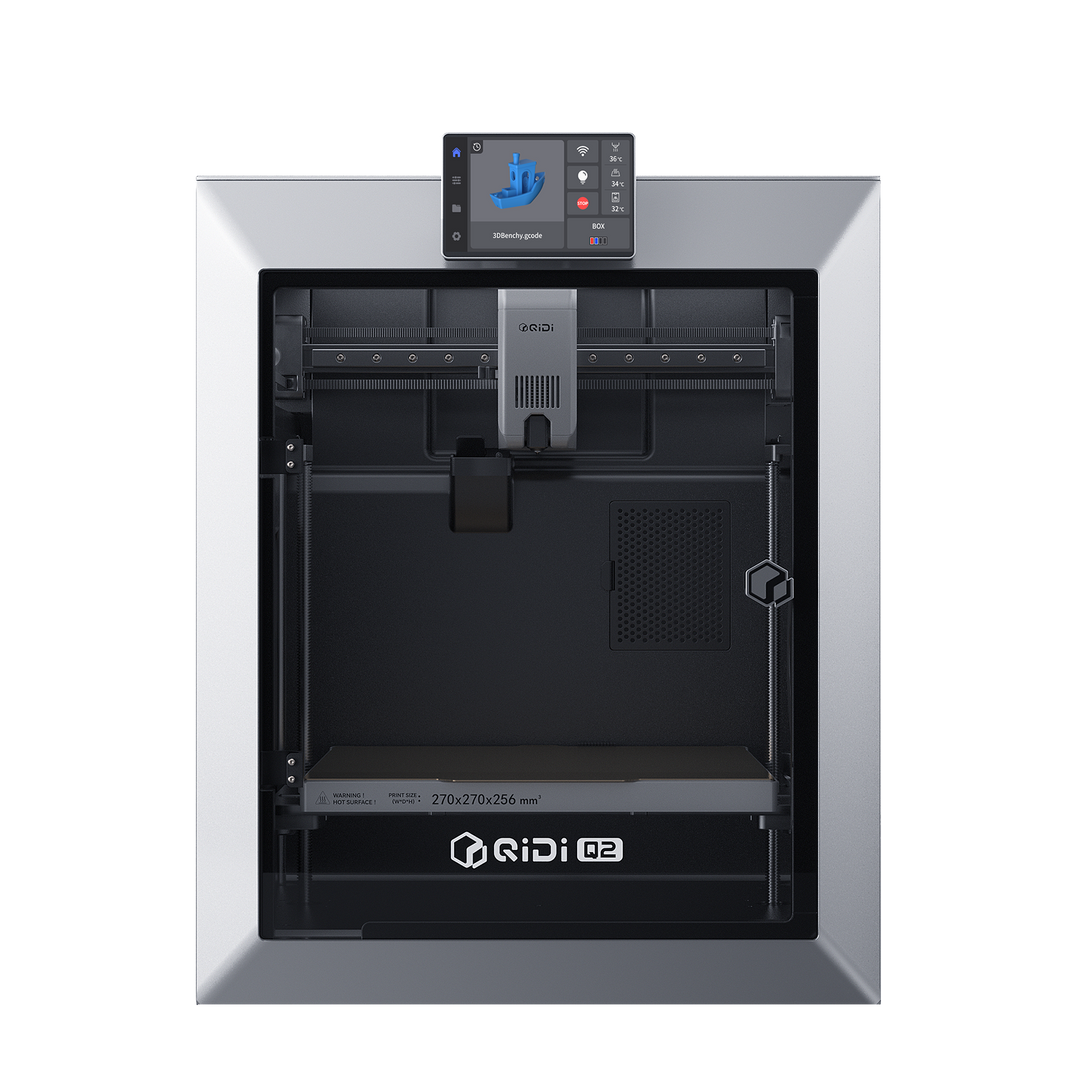

Q2

Q2