¿Cómo funciona una impresora 3D?

Una impresora 3D construye objetos físicos añadiendo material capa a capa a partir de diseños digitales. Estas máquinas se han convertido en herramientas valiosas en muchos campos: los ingenieros las utilizan para crear prototipos, los médicos crean dispositivos médicos y los aficionados crean piezas personalizadas en casa. La impresora trabaja con diversos materiales, principalmente plásticos, pero también compuestos especiales, siguiendo instrucciones digitales precisas para colocar cada capa en el lugar exacto. Esta tecnología permite producir formas complejas y artículos únicos personalizados que serían difíciles de fabricar de otra manera.

Componentes principales de una impresora 3D

Una impresora 3D Necesita cinco partes principales para funcionar correctamente. Cada componente desempeña una función específica al convertir diseños digitales en objetos físicos.

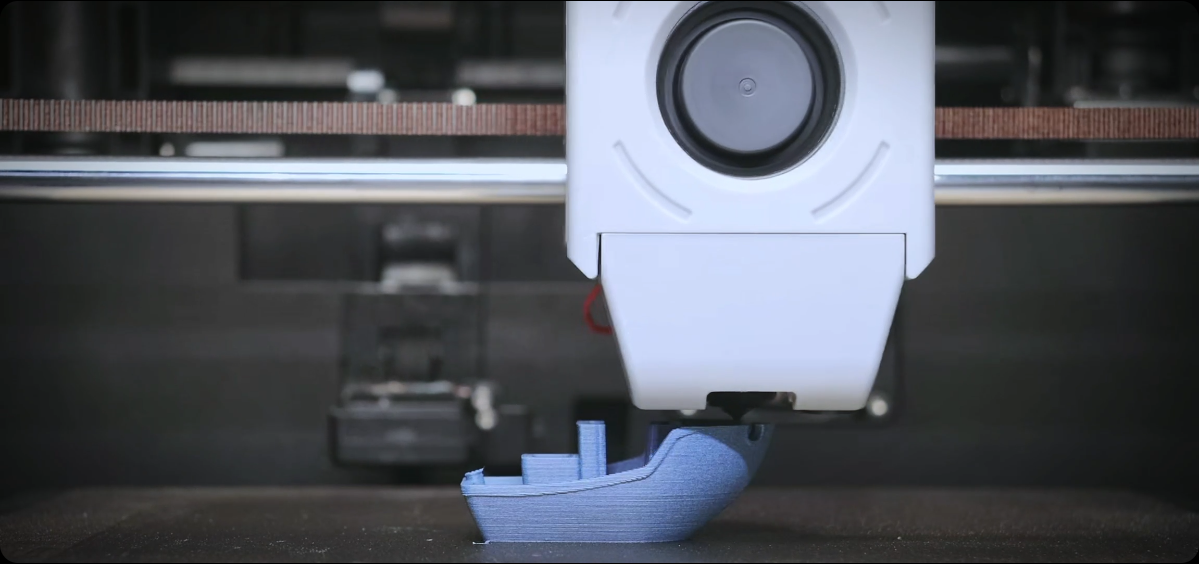

Cabezal de impresión y extrusor

El cabezal de impresión contiene el extrusor, que funde y coloca el material de impresión. Calienta el filamento plástico y lo impulsa a través de una pequeña boquilla. El tamaño de la boquilla influye en el nivel de detalle de las impresiones.

Plataforma de construcción

La plataforma de impresión es la superficie plana donde se imprimen los objetos. Debe estar nivelada para que las impresiones se adhieran correctamente. Muchas impresoras tienen bases calefactadas para evitar que el plástico se deforme al enfriarse.

Sistema de movimiento

La impresora utiliza motores para moverse en tres direcciones:

- Izquierda/derecha (eje X)

- Adelante/atrás (eje Y)

- Arriba/abajo (eje Z)

Estos motores se mueven en pasos muy pequeños para colocar el material con precisión.

Unidad de control

La unidad de control gestiona el proceso de impresión. La mayoría de las impresoras tienen una pantalla que muestra:

- ¿Qué parte de la impresión está hecha?

- Temperatura

- Configuración de materiales

- ¿Algún problema?

Sistema de alimentación de filamentos

Este sistema transporta el material de impresión desde la bobina hasta el extrusor. Incluye:

- Un engranaje que empuja el filamento.

- Tubos que guían el material

- Piezas que mantienen la tensión adecuada

- Un sensor que comprueba si se acaba el material

Estos componentes deben funcionar juntos sin problemas para lograr una impresión exitosa. Mantenimiento regular de cada parte ayuda a prevenir problemas de impresión y garantiza una buena calidad de impresión.

¿Cómo funciona una impresora 3D?

Una impresora 3D funciona como una pistola de pegamento caliente automatizada y muy precisa. Funde material plástico y lo coloca capa por capa, siguiendo un plano digital, hasta completar el objeto final. El proceso consta de tres pasos principales.

Preparación de modelos digitales

Comienza con un archivo de modelo 3D: tu plano para imprimir. Crea uno con software CAD o descarga modelos prediseñados de sitios como Thingiverse. El modelo se procesa mediante un software de corte, que lo corta en capas finas y crea instrucciones que la impresora puede seguir. El software permite ajustar parámetros importantes como la velocidad de impresión, la temperatura y la solidez del interior del objeto.

Configuración de la impresora

La impresora requiere una configuración cuidadosa para obtener buenos resultados. Cargue el papel seleccionado. filamento de plástico A través del alimentador hasta la boquilla caliente. La cama de impresión debe estar perfectamente nivelada; puede ajustar pequeños tornillos debajo de la cama para que quede bien nivelada. Ajuste las temperaturas correctas: normalmente entre 180 y 220 °C para la boquilla y entre 50 y 60 °C para la cama, según el tipo de material.

El proceso de impresión

La impresora comienza colocando la primera capa muy lentamente. Asegúrese de que se adhiera bienLuego, construye cada capa, normalmente de 0,1 a 0,3 mm de grosor. Dentro del objeto, la impresora crea un patrón en forma de panal para mayor resistencia y ahorro de plástico. Para las piezas que cuelgan (como los brazos de una figura), la impresora añade soportes extraíbles.La boquilla se mueve con precisión en tres direcciones: izquierda-derecha, adelante-atrás y arriba-abajo, colocando el plástico derretido exactamente donde se necesita.

La calidad de impresión depende en gran medida de una configuración y unos ajustes adecuados. Los objetos pequeños pueden tardar 30 minutos, mientras que las impresiones grandes o detalladas pueden tardar varias horas.

¿Qué materiales pueden utilizar las impresoras 3D?

Las impresoras 3D pueden trabajar con muchos materiales diferentesPero el plástico sigue siendo la opción más común. Cada material tiene propiedades específicas que lo hacen adecuado para diferentes usos.

Materiales plásticos básicos

filamento PLA Es el material más fácil de imprimir. Está hecho de almidón de maíz, se imprime a temperaturas más bajas y es ideal para artículos decorativos y piezas básicas. El ABS es más resistente y soporta mejor el calor; es el mismo plástico que se usa en los ladrillos LEGO. El PETG combina una impresión fácil con una buena resistencia y es seguro para envases de alimentos. Estos materiales básicos cuestan entre 20 y 30 dólares por kilogramo.

Materiales especiales

Algunos materiales tienen propiedades únicas. El TPU es flexible como el caucho, perfecto para fundas de teléfonos o plantillas de zapatos. El nailon es extremadamente resistente y duradero, ideal para piezas mecánicas. Los filamentos rellenos de madera contienen partículas de madera real y pueden parecer madera real. También existen materiales rellenos de metal, pero requieren impresoras especiales.

Elegir el material adecuado

Elige tu material en función de lo que estés haciendo:

- Para juguetes y artículos de exhibición.:EPL

- Para exteriores o piezas de automóvil:ABS o PETG

- Para artículos flexibles:TPU

- Para herramientas fuertes: Nailon

- Para artículos decorativos:Relleno de madera o metal

La variedad de materiales disponibles crece a medida que avanza la tecnología de impresión 3D. Se recomienda empezar con PLA básico para principiantes y luego probar otros materiales a medida que se adquiere experiencia.

¿Qué afecta la calidad de la impresión 3D?

Varios factores clave determinan si la impresión resulta suave y precisa o irregular. Ajustar estos parámetros correctamente produce mejores resultados de impresión.

Resolución y altura de capa

La altura de la capa controla el nivel de detalle de la impresión. Las capas más delgadas (0,1 mm) ofrecen superficies más suaves, pero tardan más en imprimirse. Las capas más gruesas (0,3 mm) se imprimen más rápido, pero muestran líneas visibles. El tamaño de la boquilla también es importante: una boquilla de 0,4 mm funciona bien para la mayoría de las impresiones, mientras que las de 0,2 mm permiten obtener detalles más finos.

Velocidad de impresión

Más rápido no siempre es mejor. Al imprimir demasiado rápido, las capas podrían no adherirse bien, los detalles podrían quedar desordenados y la impresora podría omitir pasos, provocando capas desplazadas. Las piezas complejas requieren velocidades más lentas, de entre 30 y 50 mm/s, para obtener mejores resultados. Las piezas sencillas pueden imprimirse más rápido, a 60-80 mm/s, pero tenga cuidado con los problemas de calidad.

Ajustes de temperatura

Cada material necesita temperaturas específicas. Imprimir a una temperatura demasiado alta provoca la formación de hilos y manchas, mientras que imprimir a una temperatura demasiado baja provoca una mala adhesión de las capas. El PLA suele imprimirse a 190-210 °C, el ABS a... 230-250 °Cy PETG a 220-245 °C. La temperatura de la base de impresión también es importante: facilita la adhesión de la primera capa y evita la deformación al enfriarse el objeto.

Refrigeración y flujo de aire

Una refrigeración adecuada ayuda a que el plástico se solidifique rápidamente tras salir de la boquilla. La mayoría de las impresoras tienen pequeños ventiladores cerca de la boquilla. Una buena refrigeración evita que el plástico se deforme y que se formen puentes irregulares donde el plástico cubre los huecos. Algunos materiales, como el ABS, necesitan menos refrigeración para evitar deformaciones, mientras que el PLA necesita más refrigeración para obtener detalles nítidos.

Calibración de la impresora

La calibración regular mantiene la precisión de la impresora. Revise la nivelación de la cama con frecuencia; es crucial para la adhesión de la primera capa. Mantenga las correas correctamente tensadas para evitar que las capas se desplacen.Ajuste los pasos del extrusor para asegurar que fluya la cantidad correcta de plástico. Verifique el diámetro del filamento, ya que afecta la cantidad de material que se imprime. Incluso pequeños errores de calibración Puede arruinar las impresiones.

¿Cuáles son las limitaciones de la impresión 3D?

A pesar de su versatilidad, la impresión 3D presenta varias limitaciones prácticas que afectan lo que se puede fabricar y su costo. Estas limitaciones ayudan a determinar si la impresión 3D es la opción adecuada para su proyecto.

Límites de volumen de construcción

La mayoría de las impresoras 3D domésticas Tienen un área de impresión limitada, normalmente de unos 200 mm x 200 mm x 200 mm. Los objetos más grandes deben imprimirse en piezas y ensamblarse. Existen impresoras más grandes, pero son mucho más caras y ocupan más espacio. Los detalles muy pequeños, inferiores a 0,5 mm, podrían no imprimirse bien debido a las limitaciones de tamaño de la boquilla.

Largos tiempos de producción

La impresión 3D no es un proceso rápido. Una funda de teléfono sencilla puede tardar de 2 a 3 horas, mientras que los objetos complejos pueden tardar días en imprimirse. La altura de la capa afecta significativamente el tiempo de impresión: reducirla a la mitad duplica el tiempo de impresión. Imprimir varios elementos a la vez ahorra tiempo, pero si una pieza falla, todas podrían verse afectadas.

Altos gastos en equipos y materiales

El costo inicial de una impresora básica oscila entre $200 y $1000. El costo del material se acumula: mientras que un kilogramo de filamento básico cuesta entre $20 y $30, los materiales especiales pueden costar mucho más. Las impresiones fallidas suponen un desperdicio de tiempo y material. El consumo de electricidad es mínimo, pero las impresoras necesitan mantenimiento y repuestos ocasionales.

Resistencia del material y restricciones de selección

No todos los materiales se pueden imprimir en 3D. La mayoría de las impresoras domésticas solo funcionan con termoplásticos. La impresión en metal requiere equipos especializados y costosos. Las piezas impresas suelen ser más resistentes que las moldeadas por inyección, especialmente en ciertas direcciones. Los colores se limitan a los disponibles en forma de filamento, y la impresión multicolor requiere equipos especiales o cambios manuales de filamento.

¡Crea objetos personalizados con impresión 3D!

La impresión 3D te permite crear objetos personalizados en casa. Aunque tiene límites de tamaño y velocidad, es ideal para crear artículos y prototipos únicos. El proceso es sencillo: diseña tu objeto, prepara la impresora y observa cómo se construye capa por capa. Empezar con materiales básicos como PLA y proyectos sencillos te ayudará a aprender el proceso. A medida que mejores tus habilidades, podrás abordar impresiones más complejas con diferentes materiales.

Q2

Q2