7 Signs You Need to Replace 3D Printer Nozzle

The nozzle of your 3D printer plays a pivotal role behind the scenes - extruding precise dollops of molten material to construct each layer seamlessly. However, wear and small damages can degrade print performance prematurely and often insidiously without proper inspection. Recognizing telltale signs of impending nozzle failure helps prevent headaches from unexpectedly clogged or underperforming machines. This guide explores key indicators, meaning it's time to proactively replace your 3D printer nozzle and restore pristine print consistency.

What is a Nozzle in a 3D Printer?

Quite literally the tip of the spear, nozzles house the business end of FDM 3D printers, defending against clogs and guiding filament appropriately. Nozzles feature a tiny precision-machined orifice slightly larger than filament thickness, allowing liquefied material to extrude efficiently under pressure while retaining dimensional precision. They then facilitate the all-important road-laying motions of print heads depositing material along programmed toolpaths.

Nozzle Materials

A variety of materials are used to construct durable and high-performance 3D printer nozzles, each with its respective advantages.

- Brass- Very affordable and thermally conductive for rapid, even heating. Softer and wears faster with abrasives. Suited for PLA, ABS, etc.

- Hardened Steel- Extremely hardwearing and durable. Resists exotic composites. Improved layer adhesion. Costs more and conducts heat slowly.

- Ruby - Exceptional hardness, heat resistance, and thermal stability. Low-friction properties prevent material from sticking. High material cost but outstanding longevity.

- Tungsten Carbide- Near diamond-like hardness, rigid strength, and abrasion resistance. Handles abrasive media well under high temperatures. Brittle.

- Copper/Nickel Alloy- Enhanced thermal properties. Low friction and anti-stick characteristics. Good all-round balance. It can be expensive.

Some 3D printer companies recognize diverse customer needs and offer flexible compatibility. For example, QIDI Tech equips models with interchangeable copper-plated and wear-resistant hardened steel nozzles. This permits users to select the best based on factors like filament type, expected longevity, and intended applications.

What Makes Nozzles Wear Out

Although well-built, a normal 3D printing routine still gradually damages nozzles over time:

1. Repeated Heating and Cooling

Turning nozzles on and off to hot and cold temperatures causes expansion stresses and cracks from fatigue. This slowly changes the nozzle material properties.

2. Abrasive Filament Materials

Many special filaments contain tiny hard bits of carbon fiber, metal powders, glow compounds, etc. These scour and scrape against the inner nozzle walls, eroding the precision hole.

3. High Temperatures

Printing advanced plastics involves keeping nozzles very hot for long periods, nearing material limits. Such extreme and sustained heat can distort tip shape and reduce alloy strength.

4. Cleaning Wear and Tear

Essential cold pulls and wipes slowly add up tiny dents and defects each time. This mechanical cleaning wears the hole size and shape.

5. Jam and Unclog Damage

Lodged filament chunks, drill-outs, and pushing jams backward also scrape and ding the nozzle hole surface finish.

Understanding these core wear reasons provides insight into carefully using and maintaining nozzles for extending lifespan.

Sign #1 - Inconsistent Extrusion

1. How to Identify Uneven Extrusion Issues

Listen for sputtering noises from the nozzle. Check prints for thin layers, gaps, or missing sections. These hints typically mean a partial clog is blocking the nozzle, limiting smooth flow. Over longer jobs, the problem gradually gets worse as output becomes less steady.

2. Implications of Poor Extrusion

Inconsistent output and nozzle obstructions directly damage print quality. At best, the quality degrades slightly with small voids or blabbing. However, at worst, variable flow causes layers to separate or shift the entire model. Printing becomes unpredictable and intolerant of complex geometries.

Since extrusion instability often links with impending nozzle failure, take it as a prompt to assess nozzle health closely and schedule replacements sooner rather than later.

Sign #2 - Declining Print Quality

1. Print Quality Issues Emerging

Aside from variable flow, other symptoms low-key manifest across print quality negatively, including:

- Stringing or wispy strands between sections.

- Random ooze blobs marring surface finish.

- Vertical lines seem misaligned.

- Progressively worsening ringing artifacts.

- Poor bridging, overhang performance.

2. The Nozzle Connection

While software calibration also influences quality, rulings that expose hardware factors. Nozzle wear opening up tiny gaps boosts oozing and alters deposition shape. Imprecise dimensions cause misplaced material trails. Loss of rigidity translates vibrations into defects.

If models gradually seem uglier without firmware changes, probing nozzle integrity and suitability merits consideration.

Sign #3 - Nozzle Clogging

1. Spotting Clog Warning Signs

Nothing stops prints faster than a jammed nozzle. Clues of a clog include the nozzle abruptly halting extrusion, the feed motor clicking loudly from excess pressure, or filament oozing out around the hotend. Stubborn chunks lodged inside and burnt plastic residues also gradually cause worsening clogs over time.

2. Impacts of Unresolved Jams

While clearing a clog offers short-term relief, recurring jams signal the nozzle needs replacement or upgrades to prevent permanent damage. Left unchecked, clogs strain the extruder and could ruin the hotend. Flawed nozzles also shed particles that can re-clog quickly.

Staying ahead of bothersome mid-print nozzle clogs involves keeping spare replacements on hand for fast swaps when needed. Schedule batch replacements as filament use adds up.

Sign #4 - Visible Nozzle Damage

1. Examples of Physical Nozzle Damage

Upon close inspection, the most obvious red flags involve visible nozzle wear or damage, including:

- Enlarged uneven extrusion opening.

- Chunks missing from the nozzle tip.

- Bent orifice ends obstructing filament paths.

2. Impacts of Nozzle Damage

Dents, gouges, and odd shapes along the nozzle throat negatively rearrange and constrain material flow. Meanwhile, bulging/tearing orifices lose dimensional precision, leading to swelling and dilation issues across prints. Defective nozzles also compound the risks of jamming, oozing, and embedding launch debris across outputs.

Clearly, damaged or eroded nozzles should become immediate replacement candidates for both print quality and printer longevity reasons before problems amplify.

Sign #5 - Material Leakage

Molten filament escaping unexpectedly around the nozzle area signals potential trouble, too. Sources of bothersome material leakage include:

1. Nozzle Not Fully Secured

If the nozzle fastener loosens mid-print, gaps open, allowing pressurized plastic to squeeze out erratically upwards. The evidence consists of webbed strands solidifying around heat blocks and threaded joints. Tackling the leak demands safely torquing the nozzle securely again.

2. Heat Creep Issues

Sometimes material oozes out higher along heat breaks instead, suggesting rising heat creep softening filament prematurely. The outgassing leaks hint at inadequate cooling and heat conduction issues needing remediation for robust printing, especially with high-temperature materials.

3. Worn Threads and Seals

Alternatively, plastic dripping down nozzles likely means barriers near the opening deteriorated over time, no longer containing material under pressure effectively. This strongly warrants replacing worn nozzle tips.

Sign #6 - Deformed Nozzle Shape

1. Nozzle Shape Significance

Seemingly inconsequential, the nozzle orifice profile actively guides extrusion quality and textures. Conical openings with thick tapering walls produce smooth, round traces with pressure focused at the crown for adhesion. Beveled rims also prevent material catching and debris accumulation from messing up the extrusion.

2. Identifying Aberrant Wear

But extensive use wears away precision geometry and desirable characteristics, including:

- Flattened nozzle tips.

- Overly angled extrusion holes.

- Asymmetric exit profiles.

- Rounded edges from burning and friction.

The resulting distorted extrusion patterns eventually show up as dimensional inaccuracies or blemished finishes on tall vertical features, especially.

Sign #7 - Frequent Filament Jams

1. Causes of Filament Jamming

Jams happen when debris clogs up and blocks the tiny nozzle hole, stopping the filament from being pulled through smoothly. While cruddy filament sometimes jams, most jams start from small bits of old plastic sticking in the nozzle, gradually building up over many prints.

2. Jam Frequency as Indicator

If clearing jams and replacing the filament only fixes things temporarily before another repeat jam soon after, it likely signals the nozzle itself needs replacing from escalating wear issues. Too many jams frequently, way more than is normal for your printer, implies the nozzle hole has accumulated defects, making reliable printing impossible.

Tracking jam rates helps determine if frustrating clogs come from increasing nozzle hole damage rather than occasional one-off filament problems. Using log prompts to address root issues.

Maintenance and Preventive Care

Nozzles are critical for quality prints. Keeping them well-maintained avoids problems. This guide shares nozzle care tips for extending lifespan.

1. Habits Extending Nozzle Lifespans

- Watch prints closely to catch problems as they emerge.

- Avoid running hotter than needed for materials.

- Prevent nozzle collisions through print bed leveling.

- Use cleaning filaments to safely purge residues.

- Gently wipe exteriors, avoiding hole damage.

- Inspect nozzle hole condition and threads before installing.

2. Controlling the Print Environment

- Enclose printers or use covers to maintain stable temps.

- Employ active ventilation, fans, and filters to capture debris.

- Keep the area clean and dust-free to prevent particle jams.

- Install protected spool holders away from gears/belts.

- Handle filament cleanly to prevent oils and foreign matter.

3. During Storage and Transport

- Cover nozzle openings or insert protective plugs.

- Detach nozzles and store safely in cases to limit mechanical damage.

- Add tape flags as a visual indicator of open hotend throats.

Adopting these practices will help nozzles deliver reliable extrusion and top-notch prints for their entire service lifetime. Additionally, proper filament storage is crucial for maintaining print quality. To learn more about filament longevity, check out our guide on How Long Does 3D Printer Filament Last.

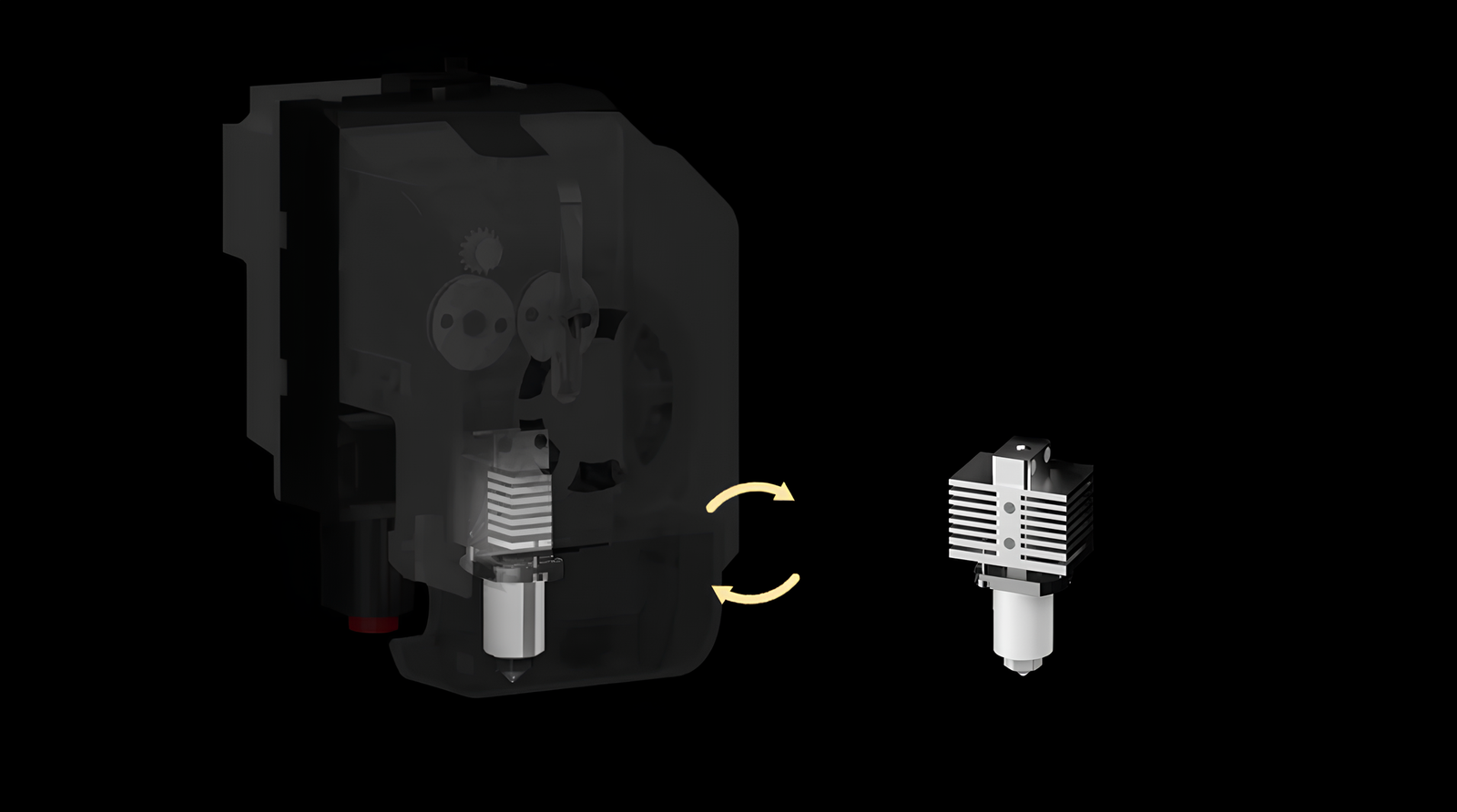

How to Replace Nozzles

When diagnosing issues, it points clearly to compromised nozzle components; replacement restores expected extrusion consistency and print quality.

1. Nozzle Replacement Procedure

With the printer safely powered down, follow these steps:

- Remove the front cover.

- Remove the silicone sheath.

- Increase nozzle temperature.

- Pull up the filament.

- Remove the nozzle with insulated gloves.

- Replace the nozzle.

- Hot-tighten the nozzle.

- Reduce nozzle temperature. Be careful of burns.

- Install the silicone sheath.

- Install the front cover.

2. Choosing Nozzle Replacements

When selecting replacements, consider:

- Orifice diameter impacts detailing capabilities.

- Material compatibility, especially with abrasives.

- Specialized anti-clog, hardened, etc, nozzles for tricky filament.

- Batch ordering affordable spares for quick exchanges when issues emerge.

With quality replacement nozzles on hand and some simple maintenance, users can nip common extrusion problems before they escalate into bigger headaches down the road.

Closing Thoughts on Nozzle Care

The 3D printer nozzle may seem insignificant, but its performance depends greatly on its durability and precision in directing material deposition. Gradual wear during standard operation can compromise extrusion reliability in subtle ways if not caught in time. By recognizing key indicators of declining nozzle health and replacing them early, users safeguard print consistency.

Q2

Q2

QIDI Box

QIDI Box

Plus 4

Plus 4

Q1 Pro

Q1 Pro

X-Max 3

X-Max 3