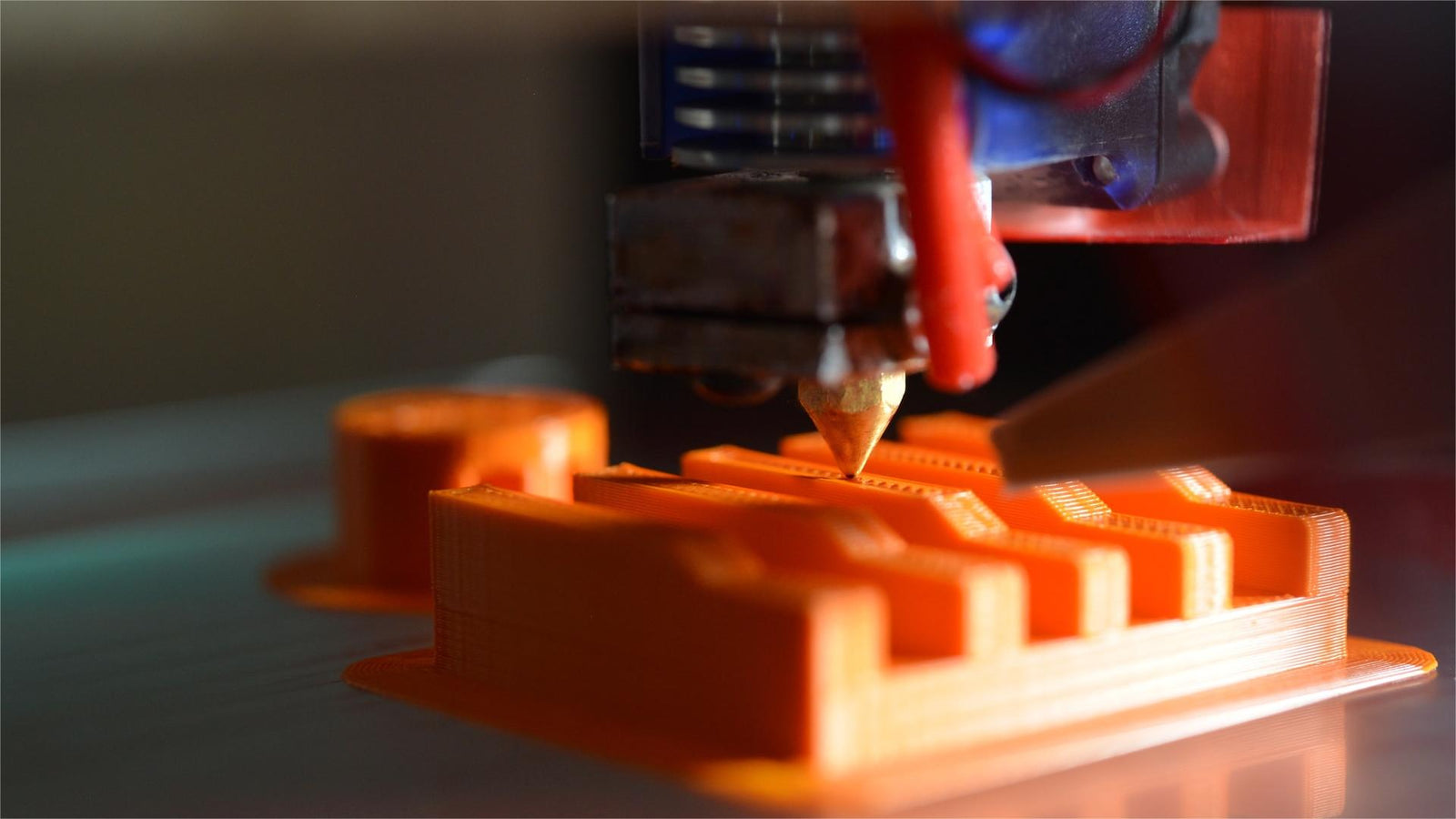

Is ABS or PLA Better for 3D Printing?

The question of ABS vs PLA has sparked heated debate in 3D printing circles for years as fused deposition modeling goes mainstream. These two common thermoplastics each offer advantages whether strength, appearance, thermal properties, printability, or safety. As adoption expands across industries, understanding key distinctions becomes critical to match filament characteristics with application goals. By evaluating precision needs, production environments, emissions, and functional demands spanning from prototypes to end-use parts, designers can leverage complementary merits of both materials or focus efforts where one clearly excels over the other. This guide illuminates the particulars behind smarter plastic selection.

A Quick Comparison about ABS vs. PLA in 3D Printing:

| Aspect | ABS | PLA |

|---|---|---|

| Strength & Durability | High impact toughness, good tensile strength, moderate chemical resistance | Lower impact resistance, but can be improved with composites |

| Printability & Precision | Good at lower nozzle temperatures, slightly better accuracy | Easier to print, more forgiving, less prone to warping |

| Ease of Use | Requires heated bed and enclosure due to warping, emits fumes | Prints well on various surfaces, minimal odor, less warping issues |

| Sustainability | Petroleum-based, less eco-friendly, not compostable | Biodegradable, made from renewable resources like cornstarch |

| Cost | Averages higher in price than standard PLA | Generally cheaper, specialty types are more expensive |

| Thermal Properties | Better heat resistance up to around 105°C | Softer above 60°C, not suitable for high-temperature applications |

| Safety | Releases styrene gas when heated, requires ventilation | Fewer harmful emissions, safer for indoor use |

| Applications | Suited for functional parts needing durability and heat resistance | Best for prototypes, non-functional models, and low-stress applications |

| Aesthetics | Can achieve a smooth finish with vapor smoothing techniques | Accepts paint easily and can look great with minimal post-processing |

Key Characteristics of ABS and PLA

1. What Is ABS in 3D Printing?

Acrylonitrile butadiene styrene (ABS) represents the classic FDM printing material, used since the technology's inception over 30 years ago. This petroleum-based plastic offers:

- Strength & Durability: ABS exhibits high impact toughness, tensile strength, and flexibility, alongside moderate heat and chemical resistance. Its resilience suits functional applications.

- High-Detail Printing:The ability to print at lower nozzle temperatures allows better accuracy and intricate features compared to other materials.

- Industry Popularity: ABS finds ubiquity especially across automotive, consumer appliance, and product design applications over decades.

2. What Is PLA in 3D Printing?

Polylactic acid (PLA) provides an increasingly popular alternative. As a bio-based plastic derived from organic feedstocks like cornstarch or sugarcane, PLA offers:

- Ease of Printing: PLA prints smoothly across nozzle temperatures while emitting a minimal odor and avoiding extreme warping issues plaguing ABS. This enables simpler prints.

- Safety:PLA produces significantly fewer harmful fumes, voiding the ABS need for dedicated ventilated enclosures during printing.

- Sustainability: Compostable PLA appeals from an environmental sustainability standpoint as waste easily biodegrades over months instead of centuries.

Print Accuracy

A key frustration facing new 3D print enthusiasts involves initial test prints gone awry. Warped corners, blobs of filament, and dimensions falling vastly outside expected values represent common grievances. When fine details make or break your application, accuracy, and precision can steer material debates from the project's onset.

1. Proper Printer Calibration

While capable of impressive resolution given optimal settings below 100 microns (0.1mm), real-world accuracy relies upon careful printer preparation. From build plate leveling and nozzle gap adjustments to filament consistency and flow rate calibrations, dialing hardware serves as the foremost accuracy checkpoint before comparing material limits.

2. Resolution Requirements

Part complexity also plays a limiting role independent of thermoplastic strengths. For example, ABS may allow intricate 40-micron channels to flow PLA's 60-micron lower threshold, but such hypothetical resolution surpasses many printer nozzle capabilities to begin with. Define must-have dimensions and tolerances using your available hardware as the baseline before assessing options.

3. Material Properties

Vendor data suggests ABS holds a slight accuracy advantage, capable of printing end-use pieces and assemblies within a 0.5mm dimensional tolerance. PLA prints tend toward 200-micron tolerances on commercial systems due to increased viscosity and cooling-related shrinkage. This favors ABS for tight-fitting components like snap joints. That said, several post-processing techniques can enhance accuracy when requirements demand.

Cost and Sourcing Analysis

Filament expenses add up over long prototyping and production workflows. While no financial dealbreaker alone, understanding pricing and sourcing can streamline planning on bigger scales.

1. Filament Cost Comparison

Standard PLA filaments retail for around $20 per 1kg spool from industrial sources. Specialty blends and composites featuring higher infill or additives for improved strength and flexibility push closer to $30 per kg.

ABS filaments average slightly higher at $22-35 per kg depending on purity and manufacturing processes. Most consumed as production materials, bulk purchasing drops ABS prices below premium PLA composites in mass quantity.

2. Sourcing Options and Availability

Thanks to widespread adoption in additive manufacturing and bioplastic initiatives, most online suppliers provide multiple PLA material varieties on-demand with cost-efficient global shipping from all major filament producers. While fewer brick-and-mortar stores locally stock specialty PLAs, widespread e-commerce access keeps chosen blends on your doorstep fast.

ABS access requires careful supplier selection, as fewer makers cater production runs given PLA's market dominance. Lead times for specialty ABS blends often take 1-3 weeks to produce on order. Check manufacturers for available ABS filaments before sourcing the niche material.

Ease of Use When Printing

Ask any 3D printing veteran to recount their most frustrating user experience - chances are they'll describe failed prints with warped and peeled layers among strewn ABS shards. Temperamental sensitivity plagues ABS, requiring dialed environmental controls. Learn processes boosting first-time print success.

1. Getting Bed Adhesion Right

PLA's forgiving flexibility enables strong bed adhesion across surfaces like tape, PEI sheets, or glue at nozzle temperatures between 185° - 220°C. ABS needs up to 110°C heated print beds, risking energy waste and fire hazards without automated controls.

2. Preventing Warpage Problems

ABS warping also frequently occurs as higher nozzle heat (230°C+) meets cool ambient air, while PLA's lower printing temperatures resist this distortion. Warpage prevention options for improved ABS adhesion include chamber enclosures or controlled airflow around the print area.

To combat warping in ABS prints, several high-quality FDM 3D printer brands, such as QIDI Tech, have integrated advanced features like the "Chamber Active Heating for Controlled Temp". This system meticulously regulates the temperature within the print chamber, maintaining a consistent environment that significantly mitigates warpage problems.

3. Considering the Fume Factor

Meanwhile, heating ABS plastic to liquefaction temperatures releases significantly more pungent fumes than PLA's faint odor during printing. Requiring dedicated venting enclosures or filtration add-ons, offline safety equipment, operating expenses, and cleanup hassles deter casual ABS use in desktop 3D operations without such infrastructure in place.

Strength of Printed Parts

finished objects must withstand reasonable stresses expected within application environments - but do the materials differ in functional mechanical properties?

1. Impact and Tensile Performance

Industry-standard shock and tension tests determine ABS provides 2-3x impact resistance over PLA prints, withstanding up to 15-20kJ/m² before fracturing. This prevents shattering under moderate drops and collisions. Reinforced PLA composites close durability gaps in near-ABS ranges, but standard PLA averages 4-6kJ/m² impact thresholds by comparison before snapping.

2. Thermal Qualities Under Load

Enclosed device environments also reveal ABS retains higher strength than PLA between -20°C and 80°C. As operating temperatures fluctuate, ABS only grows more rigid while PLA softens and deforms gradually over 60°C+. Factor operating climate conditions into material performance projections.

Desired Aesthetic Qualities

Function aside, poor surface finish or unwanted transparency can undermine aesthetic applications of 3D printing in art, architecture, and industrial design fields where appearance is paramount. How do the mainstays stack up beautifying builds?

1. Smoothing Strata: Minimizing Visible Layers

In raw untampered form, ABS offers slightly smoother visible print layers straight from the nozzle thanks to quicker cooling rates which prevent pronounced layer lines plaguing vertical PLA surfaces. However, various vapor smoothing techniques allow both materials to ultimately achieve glossy injection-molded aesthetics where needed post-production.

2. Priming for Paint: Enabling Creative Options

On raw plastics, PLA accepts painting and creative post-processing like smoothing acetone vapors better than ABS, which tends to reject spray paint adhesion without rigorous sanding preparation first. No dominator emerges here. Either material satisfies creative needs with proper workflows.

Functional Thermal Limits

Whether prototyping small-batch custom enclosures or large production-line assemblies, understanding thermal behaviors determines suitable applications for both thermoplastics in heated real-world environments.

1. Defining Heat Resistance

Assuming average ambient atmospheric conditions as the operating backdrop, PLA averages a glass transition of around 60 ̊C before deforming. This thermal ceiling limits applications like hot liquid vessels or small engine parts facing moderate under-hood temperatures.

Meanwhile, ABS offers a glass transition temperature of 105 ̊C on average, expanding feasibility for hot water systems, food processing equipment, and certain automotive surrounds before reaching its heat resistance threshold.

2. Clarifying ideal Applications

With those glass points in mind as functional cut-offs, PLA works reliably below 60 ̊C operating climates like everyday household gadgets, brewing instruments or conceptual renderings not facing temperature extremes in end-use. ABS reliably withstands 80-100 ̊C+ environments in-vehicle components to housewares needing thermal buffers as products or parts.

Safety Factors: Off-Gassing and Disposal

From neighborhood workshops to industrial facilities, safety remains a priority issue surrounding wider 3D printing adoption as emissions and waste handling come under increased public regulation in recent decades.

1. VOCs and Particle Concerns

Heated ABS filament produces styrene gas and ultrafine particle (UFP) emissions toxic at certain thresholds, linked to irritation and reduced lung function particularly. Limited research on ABS emissions makes confidence here difficult, but PLA emits significantly fewer VOCs based on available emissions data thus far. Always use enclosures and breathe carefully.

2. Recycling and Biodegrading

The bioplastic properties allowing PLA filaments to naturally decompose through industrial composting offer a distinct sustainability advantage over ABS waste accumulation given most recyclers cannot process 3D printing plastics. Reclaimer support slowly grows but disposing of PLA rights remains far greener for now.

Recommending Applications: ABS vs. PLA

While technical specifications and test data inform capabilities, real-world success requires matching material behaviors with suitable applications maximizing their potential.

1. Choosing PLA Over ABS When...

Favor PLA for smooth visual prototypes, customizable tooling jigs, quick concepts, and presentation models not facing thermal demands. Any design benefiting from tougher yet biodegradable properties also makes strong functional use cases here.

2. Opting for ABS Over PLA For...

Choose ABS when engineering robust functional components and custom enclosures needing higher durability, heat resistance, and precision. Most fixtures and end-user products facing notable strain and climate stress practically require ABS properties to perform reliably long-term.

3. Considering a Hybrid Approach

For ultra-demanding applications, a hybrid approach leverages complementary advantages. Lightweight PLA mock-ups guide form factors refined in robust ABS execution. Creative PLA signage adorns rugged ABS housing structures optimized afterward. Combine strengths strategically.

Contextualize Material to Needs

No universally "better" material exists between popular ABS and PLA filaments. Part accuracy, strength necessities, operating conditions, emissions, disposal plans, and application goals together inform ideal material selection on a case-by-case basis. Sustainability concerns increasingly prioritize renewable bioplastics like PLA for short-run fabrication less reliant on functionality. For engineers, ABS retains valued resiliency across decades of proven industrial performance. Yet striking the right balance between these thermoplastics elevates both through leveraging complementary strengths contextually. Specify your aims, appraise the trade-offs, and simplify decisions by matching intended uses with ideal properties these classic materials each provide.

Q2

Q2

QIDI Box

QIDI Box

Plus 4

Plus 4

Q1 Pro

Q1 Pro

X-Max 3

X-Max 3