Was ist der Unterschied zwischen Hobby und kommerziellen 3D -Druckern?

3D-Druck hat die Art und Weise, wie wir Objekte erstellen und herstellen, verändert und bietet eine vielseitige und zugängliche Technologie für Hobbyisten und Profis. Da der 3D-Druck immer beliebter wird, ist es wichtig, die Unterschiede zwischen Hobby- und kommerziellen 3D-Druckern zu verstehen.

Ein kurzes Vergleichsblatt:

| Besonderheit | Hobbydrucker | Kommerzieller Drucker |

|---|---|---|

| Kosten | 200 bis 5.000 US-Dollar | 5.000 bis 1.000.000 USD und mehr |

| Druckgeschwindigkeit | Langsam | Schnell |

| Druckqualität | Gut | Exzellent |

| Materialien | PLA, ABS, PETG | Fortschrittliche Kunststoffe, Metalle, Keramik |

| Baugröße | Klein | Groß |

| Leistung &Amp; Geschwindigkeit | Langsamer, geeignet für persönliche Projekte | Schneller, ideal für die Massenproduktion |

| Druckqualität &Amp; Präzision | Gute Druckqualität, Einschränkungen bei der Auflösung | Überlegene Qualität, feinere Details, glattere Oberflächen |

| Baugröße &Verstärker; Lautstärke | Begrenzte Größe für Objekte | Größere Bauplattformen für größere Objekte |

| Materialverträglichkeit | Eingeschränkte Auswahl (PLA, ABS, PETG) | Größere Bandbreite (Hochleistungskunststoffe, Metalle, Keramik) |

| Software & Benutzeroberfläche | Benutzerfreundlich, eingeschränkte Funktionen | Komplexe, erweiterte Funktionen, steilere Lernkurve |

| Wartung &Amp; Haltbarkeit | Leichter zu warten, einfacheres Design | Regelmäßige Wartung erforderlich, robuste Konstruktion |

| Kosten &und ROI | Günstige Anschaffungskosten, möglicherweise höhere Betriebskosten | Hohe Anfangsinvestition, besserer langfristiger Wert |

Was sind Hobby-3D-Drucker?

Hobby-3D-Drucker sind für den persönlichen Gebrauch und kleine Projekte gedacht. Sie sind in der Regel erschwinglich, mit Preisen zwischen einigen hundert und einigen tausend Dollar, so dass sie für viele Menschen erschwinglich sind. Diese Drucker verwenden oft gemeinsame Materialien wie PLA, ABS und PETG, die einfach zu handhaben und leicht zu finden sind.

Einer der größten Vorteile von Hobby-3D-Druckern ist ihre Benutzerfreundlichkeit. Sie werden oft mit benutzerfreundlicher Software geliefert und sind schnell eingerichtet, sodass auch Anfänger sofort mit dem Drucken beginnen können. Hobbydrucker eignen sich hervorragend für die Herstellung kleiner Objekte, Prototypen und individueller Artikel wie Spielzeug, Figuren und Haushaltsgeräte.

Was sind kommerzielle 3D-Drucker?

Kommerzielle 3D-Drucker sind für den industriellen Einsatz und die Massenproduktion konzipiert. Sie verfügen über erweiterte Funktionen, funktionieren besser und sind präziser als Hobbydrucker. Kommerzielle Drucker kosten in der Regel mehr und reichen je nach Ausstattung und Größe von mehreren Tausend bis zu Hunderttausenden von Dollar.

Kommerzielle 3D-Drucker können viele verschiedene Materialien verwenden, darunter Hochleistungskunststoffe, Metalle, Keramikund Verbundwerkstoffe. Diese Materialien ermöglichen die Herstellung von Funktionsteilen, Werkzeugen und Fertigprodukten. Kommerzielle Drucker können Objekte mit höherer Präzision, glatteren Oberflächen und einer besseren Gesamtstruktur herstellen.

Wichtige Unterschiede zwischen Hobby- und kommerziellen 3D-Druckern

1. Leistung und Geschwindigkeit

Einer der bedeutendsten Unterschiede zwischen Hobby- und kommerziellen 3D-Druckern ist ihre Leistung und Geschwindigkeit. Kommerzielle Drucker bieten in der Regel höhere Druckgeschwindigkeiten, was kürzere Durchlaufzeiten und höhere Ausgabemengen ermöglicht. Dies ist besonders wichtig für Unternehmen, die auf 3D-Druck für die Produktion angewiesen sind oder Schnelles PrototypingHobbydrucker sind zwar langsamer, eignen sich aber dennoch für die meisten persönlichen Projekte und Anwendungen im kleinen Maßstab.

2. Druckqualität und Präzision

Kommerzielle 3D-Drucker bieten im Allgemeinen eine höhere Druckqualität und Präzision als Hobbydrucker. Sie können Objekte mit feineren Details, glatteren Oberflächen und höherer Maßgenauigkeit herstellen. Dieses Maß an Präzision ist für die Herstellung funktionaler Teile, Formen und Endprodukte unerlässlich. Hobbydrucker können zwar qualitativ hochwertige Drucke produzieren, weisen jedoch möglicherweise Einschränkungen hinsichtlich Auflösung und Oberflächenbeschaffenheit auf.

3. Baugröße und Volumen

Ein weiterer wichtiger Unterschied zwischen Hobby- und kommerziellen 3D-Druckern ist ihre Baugröße und ihr Volumen. Kommerzielle Drucker haben oft größere Bauplattformen, wodurch die Erstellung größerer Objekte oder mehrerer kleinerer Objekte in einem einzigen Druckvorgang möglich ist. Dies ist besonders nützlich für industrielle Anwendungen, bei denen größere Komponenten oder höhere Produktionsmengen erforderlich sind. Hobbydrucker haben in der Regel kleinere Bauvolumina, was die Größe der druckbaren Objekte begrenzt.

4. Materialverträglichkeit

Kommerzielle 3D-Drucker bieten im Vergleich zu Hobbydruckern eine größere Auswahl an Materialien. Sie können mit modernen Materialien arbeiten, wie z. B. Hochleistungskunststoffe, Metalle, Keramik und Verbundwerkstoffe, die häufig für industrielle Anwendungen benötigt werden. Einige kommerzielle Drucker unterstützen sogar Spezialmaterialien mit einzigartigen Eigenschaften wie hoher Hitzebeständigkeit oder elektrischer Leitfähigkeit. Hobbydrucker hingegen arbeiten hauptsächlich mit einer begrenzten Auswahl gängiger Materialien wie PLA, ABS und PETG.

5. Software und Benutzeroberfläche

Der Software Auch die Benutzeroberfläche von Hobby- und kommerziellen 3D-Druckern kann sich erheblich unterscheiden. Hobbydrucker werden oft mit benutzerfreundlicher, vereinfachter Software geliefert, die selbst für Anfänger leicht zu bedienen ist. Diese Softwarelösungen verfügen zwar über eingeschränkte erweiterte Funktionen, reichen aber für die meisten Hobby-Anforderungen aus. Kommerzielle Drucker hingegen verfügen oft über komplexere Software und erfordern eine steilere Lernkurve. Diese fortschrittlichen Softwarelösungen bieten jedoch mehr Kontrolle, Anpassungsmöglichkeiten und Automatisierungsfunktionen, die für industrielle Anwendungen unerlässlich sind.

6. Wartung und Haltbarkeit

Kommerzielle 3D-Drucker sind in der Regel für Dauerbetrieb und lange Lebensdauer ausgelegt. Sie bestehen aus hochwertigen Komponenten und sind robust konstruiert, um den Anforderungen des industriellen Einsatzes standzuhalten. Diese Drucker benötigen möglicherweise regelmäßige Wartung und technischen Support, um optimale Leistung und Langlebigkeit zu gewährleisten. Hobbydrucker sind zwar nicht so langlebig wie ihre kommerziellen Gegenstücke, aber aufgrund ihrer einfacheren Konstruktion und der größeren Verfügbarkeit von Ersatzteilen im Allgemeinen leichter zu warten und zu reparieren.

Weiterführende Literatur: Fehlerbehebung beim 3D-Druck: Die 15 häufigsten Probleme & Lösungen

7. Kosten und Kapitalrendite

Die Kosten und die Kapitalrendite für Hobby- und kommerzielle 3D-Drucker kann erheblich variieren. Hobbydrucker sind in der Anschaffung günstiger und somit für einen größeren Nutzerkreis zugänglich. Allerdings können die Betriebskosten im Verhältnis zur Leistung in Bezug auf Material und Energieverbrauch höher sein.Kommerzielle Drucker erfordern zwar eine höhere Anfangsinvestition, bieten aber langfristig einen besseren Wert für Unternehmen, die stark auf 3D-Druck angewiesen sind. Die höhere Produktivität, Präzision und Materialvielfalt kommerzieller Drucker können langfristig zu einer besseren Kapitalrendite führen.

Wann sollte man vom Hobby- zum kommerziellen 3D-Druck übergehen?

Mit zunehmender Erfahrung im 3D-Druck möchten Sie möglicherweise größere und komplexere Projekte in Angriff nehmen. Wenn Ihr Hobbydrucker nicht mehr ausreicht, ist es möglicherweise an der Zeit, auf ein professionelles Gerät umzusteigen. Hier sind einige Anzeichen dafür, dass Sie für den Umstieg bereit sind:

- Sie müssen größere Objekte drucken, die nicht auf die Bauplatte Ihres Hobbydruckers passen

- Ihre Projekte erfordern sehr präzise Details und glatte Oberflächen, die Ihr aktueller Drucker nicht erreichen kann

- Sie möchten mit modernen Materialien wie Metall oder Hochleistungskunststoffen experimentieren

Unternehmen, die in einen kommerziellen 3D-Drucker investieren möchten, sollten ihre spezifischen Anforderungen und ihr Budget sorgfältig abwägen. Stellen Sie sich folgende Fragen:

- Wofür werden Sie den Drucker verwenden? Für unterschiedliche Anwendungen sind möglicherweise unterschiedliche Druckertypen und Materialien erforderlich.

- Wie hoch muss die Druckqualität sein? Wenn Sie funktionale Teile oder Produkte herstellen, benötigen Sie wahrscheinlich die Präzision und Zuverlässigkeit einer kommerziellen Maschine.

- Wie viele Objekte werden Sie drucken? Wenn Sie eine große Menge an Artikeln produzieren müssen, sind die Geschwindigkeit und Effizienz eines kommerziellen Druckers von entscheidender Bedeutung.

- Welche Materialien benötigen Sie zum Arbeiten? Stellen Sie sicher, dass der von Ihnen gewählte Drucker mit den spezifischen Kunststoffen, Metallen oder anderen Materialien kompatibel ist, die für Ihre Projekte erforderlich sind.

Die Beantwortung dieser Fragen hilft Ihnen dabei, den richtigen kommerziellen 3D-Drucker für Ihre Anforderungen zu finden und sicherzustellen, dass Sie eine kluge Investition tätigen.

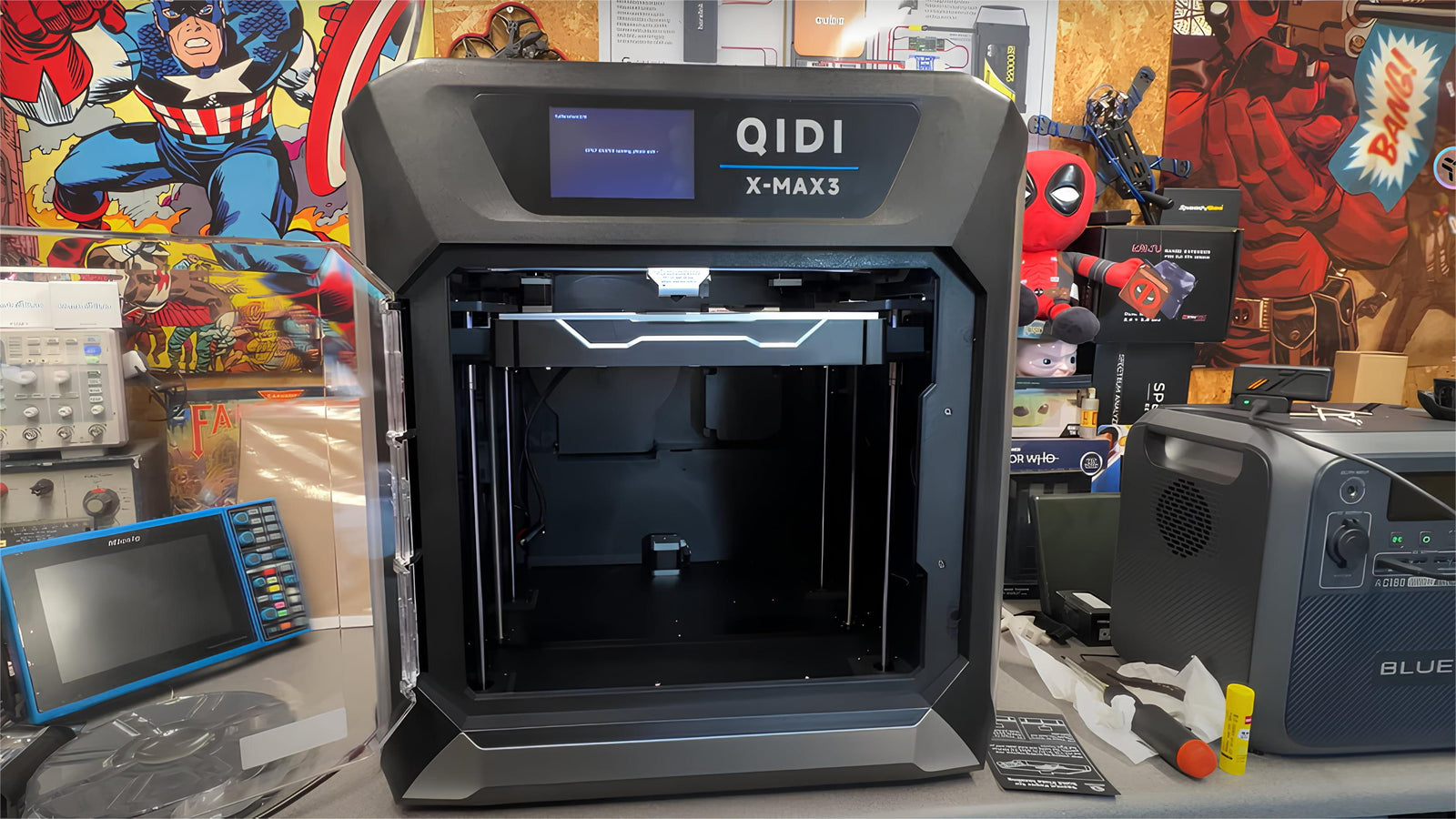

QIDI 3D-Drucker: Die Brücke zwischen Hobby und Gewerbe

Obwohl der Übergang vom Hobby- zum kommerziellen 3D-Druck teuer und schwierig sein kann, gibt es innovative Optionen, die die Lücke zwischen den beiden Kategorien schließen.

Mit einem

Von Überbrückung der Lücke zwischen Hobby- und kommerziellen Druckern,

Finden Sie den perfekten 3D-Drucker für Ihre Ziele!

Um den richtigen 3D-Drucker auszuwählen, sollten Sie Ihre Bedürfnisse und Ziele berücksichtigen. Hobbydrucker eignen sich hervorragend für Anfänger und kleine Projekte, während kommerzielle Drucker besser für Unternehmen und fortgeschrittene Anwendungen geeignet sind. Wenn Sie im 3D-Druck besser werden, sollten Sie für größere Herausforderungen möglicherweise auf einen kommerziellen Drucker umsteigen. Wenn Sie das beste Werkzeug für Ihre Aufgabe auswählen, sind Sie bereit, mit 3D-Druck erstaunliche Dinge zu schaffen.Entdecken Sie diese spannende Technologie noch heute und sehen Sie, was Sie damit erreichen können!

FAQs zu Hobby- und kommerziellen 3D-Druckern

F: Welche Arten von Materialien sind mit kommerziellen 3D-Druckern kompatibel?

A: Alle Arten von technischen Kunststoffen, Verbundwerkstoffen, Metallen wie Edelstahl und Titan, Keramik und mehr. Die Materialauswahl ist im Vergleich zu Hobbydruckern riesig.

F: Können kommerzielle 3D-Drucker funktionsfähige Teile und Produkte herstellen?

A: Ja, ihre Präzision und die fortschrittlichen Materialeigenschaften ermöglichen es ihnen, langlebige Endverbrauchsteile für alle Arten von Industrieanwendungen herzustellen. Die Qualität ist Hobbydruckern weit überlegen.

F: Welche Branchen nutzen kommerziellen 3D-Druck?

A: Luft- und Raumfahrt, Automobilindustrie, Gesundheitswesen, Architektur, Konsumgüter und mehr. Jede Branche, die Teile, Werkzeuge, Formen oder andere physische Objekte herstellt, profitiert vom kommerziellen 3D-Druck.

F: Welche Faktoren sollte ich bei der Auswahl eines kommerziellen 3D-Druckers berücksichtigen?

A: Bauvolumen, Präzisionsbewertung, Materialanforderungen, Softwarepräferenzen, Betriebsbudget, Durchsatzanforderungen und Nachbearbeitungsmöglichkeiten. Die Kombination dieser Faktoren mit Ihren Anforderungen kann Ihnen helfen, die beste Wahl zu treffen.

F: Welche Vorteile bietet der kommerzielle 3D-Druck gegenüber anderen Fertigungsmethoden?

A: Höhere Designflexibilität, kürzere Vorlaufzeiten, werkzeug- und formenlose Produktion, konsolidierte Baugruppen, weniger Abfall, Fertigung vor Ort, Massenanpassung und mehr. Es ist eine transformative Technologie.

Q2

Q2