كم من الوقت تستمر طابعة ثلاثية الأبعاد؟

باعتبارك من المتحمسين أو المحترفين في مجال الطباعة ثلاثية الأبعاد، فمن المرجح أنك دهشت من الإبداعات المذهلة التي تستطيع طابعتك إنتاجها. هل تساءلت يومًا كم من الوقت ستستمر طابعتك ثلاثية الأبعاد في تجسيد أفكارك؟ إن طول عمر طابعتك ثلاثية الأبعاد ليس مجرد فضول، بل هو عامل حاسم يؤثر على إنتاجيتك وفعاليتك من حيث التكلفة، بل وحتى جودة مطبوعاتك. سواء كنت تدير مشروعًا يعتمد على الطباعة ثلاثية الأبعاد أو كنت هاويًا مستثمرًا في هذه التقنية، فإن فهم كيفية إطالة عمر طابعتك إلى أقصى حد يمكن أن يوفر عليك الوقت والمال والجهد. من التآكل والتلف في الأجزاء الميكانيكية إلى تأثير المواد المختلفة وترددات الطباعة، تؤثر عوامل عديدة على مدة عمل طابعتك ثلاثية الأبعاد.

العوامل الرئيسية التي تحدد عمر الطابعة ثلاثية الأبعاد الخاصة بك

1. الجودة مهمة: أساس المتانة

غالبًا ما تقدم العلامات التجارية العريقة طابعات أكثر متانة. ابحث في تقييمات المستخدمين وتقارير الصناعة لتقييم موثوقيتها قبل الشراء. عادةً ما تستثمر العلامات التجارية المرموقة أكثر في البحث والتطوير، مما ينتج عنه طابعات تدوم لفترة أطول.

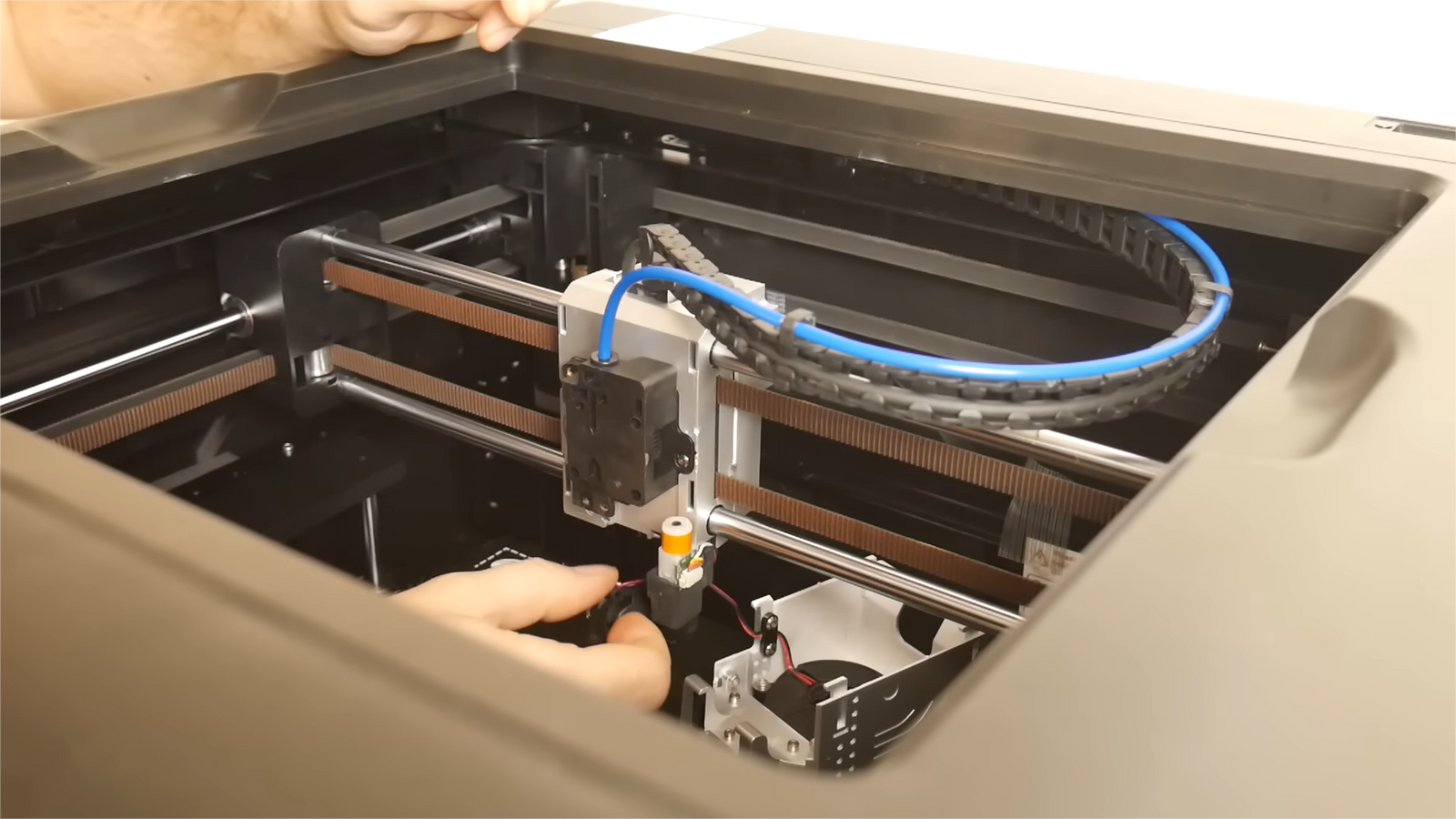

ابحث عن طابعات ذات إطارات متينة، ويفضل أن تكون معدنية بدلًا من البلاستيكية. تُطيل المحركات والمحامل والمكونات الإلكترونية عالية الجودة عمر طابعتك بشكل ملحوظ. كما تلعب المواد المستخدمة في التصنيع دورًا حاسمًا في المتانة الإجمالية.

2. أنماط الاستخدام: عامل عبء العمل

الطابعة المستخدمة يوميًا تتآكل أسرع من الطابعة المستخدمة أحيانًا. مع ذلك، الاستخدام المتكرر لا يضر بالضرورة إذا اقترن بالصيانة المناسبة. ضع في اعتبارك أنماط استخدامك عند تخطيط جداول الصيانة.

تُرهق كل مهمة طباعة مكونات مختلفة. ترتفع درجة حرارة المحركات، وتتمدد الأحزمة، وتتآكل الفوهات بمرور الوقت. يُساعد فهم هذا التأثير التراكمي في التخطيط للصيانة الدورية واستبدال القطع.

3. الصيانة: مفتاح طول العمر

التنظيف المستمر والصيانة أمران أساسيان. أزل الغبار والحطام بانتظام، وقم بتزييت الأجزاء المتحركة، ضمان المعايرة المناسبةلا تدوم الطابعة النظيفة لفترة أطول فحسب، بل تنتج أيضًا مطبوعات ذات جودة أفضل.

ضع جدول استبدال استباقي للأجزاء الاستهلاكية، مثل الفوهات والأحزمة، حسب استخدامك. هذا يمنع الأعطال غير المتوقعة ويحافظ على جودة الطباعة. لا تنتظر حتى تتعطل الأجزاء تمامًا قبل استبدالها.

عمر المكونات الرئيسية للطابعة ثلاثية الأبعاد

1. الأجزاء الميكانيكية

- المحركات والمحامل: العناصر الأساسية للطابعة الخاصة بك، تستمر المحركات والمحامل عادةً لمدة تتراوح من 5 إلى 7 سنوات مع الصيانة المناسبة، قد تؤدي الحرارة وقلة التزييت وتراكم الغبار إلى تقصير عمرها الافتراضي. التنظيف والتزييت المنتظمان أساسيان لإطالة عمرها.

- الأحزمة والبكرات: عادةً ما تتطلب الأحزمة استبدالًا كل 6-18 شهرًا، بينما يمكن أن تدوم البكرات لعدة سنوات إذا تمت صيانتها جيدًا. انتبه لعلامات التآكل مثل التآكل. أصوات غير عادية، أو فقدان دقة الطباعة.

2. مجموعة الطارد

- تآكل الفوهة: تتعرض الفوهات للتآكل المستمر بسبب الخيوط الكاشطة ودرجات الحرارة المرتفعة. قد تحتاج فوهات النحاس إلى الاستبدال بعد شهر إلى ثلاثة أشهر من الاستخدام المنتظم، بينما تدوم فوهات الفولاذ المقسّى لفترة أطول. يؤثر نوع الخيط ودرجة حرارة الطباعة وسرعتها على تآكل الفوهة.

- تروس الطارد: تدوم تروس الطارد عادة 1-2 سنة. لكن،

QIDI تستخدم الطابعات ثلاثية الأبعاد تروسًا فولاذية صلبة، والتي يمكن أن تدوم لفترة أطول بشكل كبير.

3.سرير الطباعة

- مادة السطح والمتانة: يختلف عمر ألواح الطباعة باختلاف المادة. تدوم ألواح الطباعة الزجاجية لفترة طويلة إذا تم التعامل معها بعناية، بينما قد تحتاج الألواح المرنة إلى استبدال كل 3-6 أشهر.

- تأثيرات دورات التسخين المتكررة: يمكن أن يؤدي التسخين والتبريد المستمر إلى إجهاد سرير الطباعة الخاص بك بمرور الوقت، مما قد يؤدي إلى التشويه أو مشاكل في الالتصاق. لإطالة عمر المنتج، اسمح بتبريده بشكل طبيعي، ونظفه برفق بين المطبوعات، وتجنب استخدام القوة المفرطة عند إزالته.

إن معرفة أعمار المكونات ضرورية لتخطيط الصيانة والاستبدال في الوقت المناسب. فهي تضمن الحفاظ على أداء الطابعة الأمثل على مر السنين.

كيف تؤثر مواد الطباعة على عمر الطابعة ثلاثية الأبعاد الخاصة بك

1. عالم مواد الطباعة ثلاثية الأبعاد المتنوع

تتراوح مواد الطباعة ثلاثية الأبعاد من البلاستيك الشائع مثل PLA وABS، وصولاً إلى الخيوط الغريبة المُضاف إليها إضافات خشبية أو معدنية. لكل مادة تأثير مختلف على طابعتك. PLA لطيف على الطابعات، بينما يتطلب ABS درجات حرارة أعلى قد تُسبب إجهاداً للمكونات. الخيوط الغريبة المُضاف إليها إضافات قد تكون كاشطة بشكل خاص. تُشكل الراتنجات المُستخدمة في طابعات SLA تحديات فريدة، حيث يُسبب بعضها ضغطاً إضافياً على آليات الطابعة بسبب لزوجتها.

2. التآكل والتآكل الناتج عن المواد

تتفاعل المواد المختلفة مع مكونات الطابعة بطرق مختلفة. فالخيوط الكاشطة قد تُسبب تآكلًا سريعًا للفوهات، بينما قد تُسبب بعض المواد تآكلًا في تروس الطارد. وقد تُسبب بعض الراتنجات تدهورًا في أجزاء الطابعة البلاستيكية بمرور الوقت. لذا، يُعد فهم هذه التفاعلات أمرًا بالغ الأهمية للحفاظ على عمر طابعتك.

3. العوامل البيئية وتخزين المواد

تؤثر البيئة بشكل كبير على جودة المواد وأداء الطابعة. قد تتسبب الرطوبة في امتصاص خيوط الطباعة للرطوبة، مما يؤدي إلى طباعة رديئة. كما قد تؤثر تقلبات درجات الحرارة على خصائص المواد. يمكن أن يؤدي التعرض للأشعة فوق البنفسجية إلى تدهور بعض المواد أو معالجتها قبل الأوانيؤدي التخزين المناسب في حاويات محكمة الغلق، بعيدًا عن الحرارة والضوء، إلى الحفاظ على جودة المواد وحماية الطابعة من التلف المحتمل.

ما هي المدة التي تستمر فيها الطابعة ثلاثية الأبعاد؟

إن عمر الطابعة ثلاثية الأبعاد ليس رقمًا ثابتًا، بل هو نطاق يتأثر بعوامل متعددة. في حين أن الطابعة المتوسطة التي يتم صيانتها جيدًا يمكنها أن تعمل بشكل فعال لمدة 1 إلى 3 سنوات قبل الحاجة إلى إصلاحات كبيرةيمكن أن يختلف هذا الإطار الزمني بشكل كبير بناءً على جودة الطابعة واستخدامها والعناية بها.

طابعات ثلاثية الأبعاد عالية الجودة من شركات مصنعة ذات سمعة طيبة، يحب

من المهم ملاحظة أن العمر الافتراضي للطابعة ثلاثية الأبعاد لا يعكس بالضرورة متانة جميع مكوناتها. تتآكل أجزاء الطابعة بمعدلات مختلفة، حيث يتطلب بعضها الاستبدال بوتيرة أعلى بكثير من غيرها. على سبيل المثال، بينما قد يدوم هيكل الطابعة وبنيتها الرئيسية لسنوات عديدة، قد تحتاج مكونات مثل الفوهات والأحزمة وأحواض الطباعة إلى الاستبدال على مدى أشهر وليس سنوات.

إن مفتاح زيادة عمر الطابعة الخاصة بك يكمن في فهم أعمار هذه المكونات المتنوعة وتنفيذ استراتيجية صيانة استباقية. من خلال استبدال الأجزاء المعرضة للتآكل قبل فشلها ومواكبة التنظيف والمعايرة بشكل منتظم، يمكنك إطالة العمر الإنتاجي للطابعة بشكل كبير.لا يؤدي هذا النهج إلى زيادة عمر جهازك فحسب، بل يضمن أيضًا جودة طباعة ثابتة ويقلل من احتمالية حدوث أعطال غير متوقعة.

في نهاية المطاف، فإن النظر إلى عمر الطابعة ثلاثية الأبعاد الخاصة بك باعتباره نتاجًا لجهود العناية والصيانة، وليس تاريخ انتهاء صلاحية محدد مسبقًا، يمكن أن يساعدك في الحصول على أقصى قيمة وإنتاجية من استثمارك.

كيفية زيادة عمر الطابعة ثلاثية الأبعاد الخاصة بك

يعتمد عمر طابعتك ثلاثية الأبعاد بشكل كبير على كيفية استخدامها وصيانتها. باتباع بعض الممارسات البسيطة، يمكنك إطالة عمرها الافتراضي بشكل ملحوظ وضمان جودة طباعة ثابتة.

1. ممارسات التشغيل المثلى

- اتبع إعدادات الطباعة الموصى بها من قبل الشركة المصنعة لتقليل التآكل والتلف.

- وازن بين سرعة الطباعة والجودة لتجنب إجهاد المحركات.

2. الصيانة الاستباقية

- تنفيذ عمليات التفتيش المنتظمة: عمليات التفتيش الأسبوعية، والمعايرات الشهرية، والتنظيف ربع السنوي.

- حافظ على الأجزاء المتحركة نظيفة ومزيتة.

- قم بتخزين الخيوط بشكل صحيح لمنع امتصاص الرطوبة.

- استبدل الأجزاء المعرضة للتآكل (الفوهات والأحزمة وأسرة الطباعة) قبل أن تفشل.

3. تحديثات البرامج الثابتة

- يحفظ البرامج الثابتة محدث، والتحقق من التوافق أولاً.

ستُطيل هذه الممارسات عمر طابعتك وتحافظ على جودة الطباعة. الصيانة الدورية والاستخدام الدقيق هما أساس الأداء طويل الأمد.

تعظيم إمكانات الطابعة ثلاثية الأبعاد الخاصة بك

في الختام، يتأثر عمر طابعتك ثلاثية الأبعاد بعوامل مختلفة، منها جودة مكوناتها، وأنماط استخدامها، وإجراءات صيانتها. بفهم عمر المكونات الرئيسية، وتأثير مواد الطباعة المختلفة، وأهمية مواكبة التطورات التكنولوجية، يمكنك اتخاذ قرارات مدروسة لإطالة عمر طابعتك. سيساعدك تطبيق ممارسات التشغيل المثلى، وإجراء الصيانة الاستباقية، وتحديث برامجك الثابتة باستمرار على تعظيم إمكانات طابعتك ثلاثية الأبعاد، وضمان استمرارها في تحقيق رؤاك الإبداعية لسنوات قادمة.

س 2

س 2