Temperature Controlled Chamber

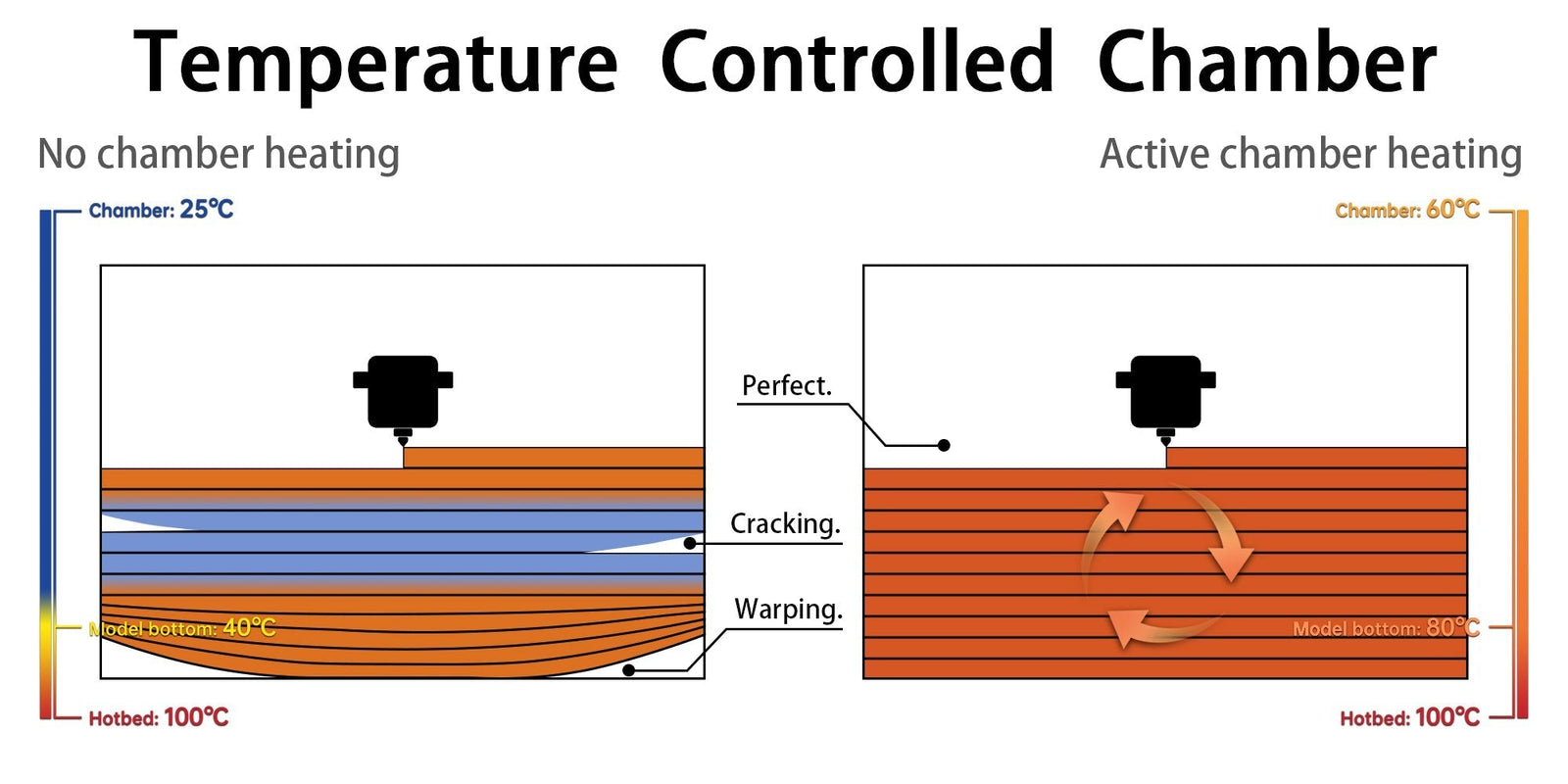

As a typical enclosed FDM 3D printer, QIDI latest Max3 and Plus3 are equipped with one of the most prominent features - temperature controlled chamber. The chamber can reach a maximum temperature of 65°C, which not only supports a wider range of high-performance filaments, but also prevents warping and cracking during the printing process. In addition, QIDI Max3 has an additional chamber circulation fan with an activated carbon air filter on the side of the chamber for better temperature regulation.

Advantages of Enclosed 3D Printers

3D printers can be categorized into enclosed 3D printers and open 3D printers. An enclosed printer is one in which the printing area is completely enclosed. Due to its closed structure, it has the following advantages:

1、Better Print Quality

Using ABS or printing larger models requires more stability from 3D printers. Considering that closed 3D printers have a stronger frame than open structure printers, it largely improves the stability of the machine, which at the same time improves the quality of the 3D prints.

2、Reduce Noise and Heat Loss

Enclosed 3D printers tend to be quieter, which is an important point for some home hobbyists. Also enclosed 3D printers are less susceptible to external airflow and dissipate less heat, allowing the printer to maintain a relatively constant temperature environment inside.

3、Safety of Use

In the 3D printing process, some parts of the printer are often in a heated state, such as nozzles, hot beds, etc. At the same time, the temperature of the internal parts can even reach more than 200℃. At this point, the structure of the closed printer effectively improves the safety of use, which can avoid users from contacting the high temperature caused by burns.

In addition, in order to use some high-performance filaments with higher temperature requirements, 3D printers need to have some features to heat and maintain the temperature, and this heated chamber can only be realized on closed 3D printers.

Classification of Temperature Controlled Chamber

1、Passively Heated Chamber

So-called passively heated chambers rely on the heat generated by the printer components (e.g. hot ends, hot beds, etc.) and the enclosed nature of the structure to heat the chamber. This can be an effective way to save energy and attempt to increase the chamber temperature. However, this typically does not support print jobs that require precise, consistent temperature control, nor does it support applications with engineering-grade filaments that are sensitive to temperature variations.

2、Actively Heated Chamber

Actively heated chambers use external heating elements, such as heating pads or additional specialized heaters, to actively set the temperature in the chamber. This type of heating system allows for more precise temperature control. Most importantly, it supports the application of engineering-grade, advanced filaments that require a specific temperature range to print correctly, as well as guarantees the print quality and dimensional accuracy of models for industrial applications. QIDI Max3 and Plus3 are equipped with actively heated chambers.

Advantages of Temperature Controlled Chamber

Industrial-grade 3D printers like QIDI Max3, as well as 3D printers designed for professional high speed printing application grade filaments like QIDI Plus3, often have actively heated chambers to ensure that consistent temperatures are maintained during the 3D printing process. An actively heated chamber is important for 3D printers because it offers a number of significant advantages, including:

1、Optimization of Filament Properties

Actively heated chamber provides better temperature control, allowing the filament to reach optimal temperatures during the printing process. Different filaments need to be printed at different temperature ranges, and with heating control, the flow, adhesion and mechanical properties of the filament can be optimized for higher quality print results. For example:

(Data Source:QIDI TECH Official Wiki - Filament Guide)

2、Reduce Thermal Stress

During the 3D printing process, the filament undergoes a rapid warming and cooling process, which is prone to thermal stress that can lead to cracking or deformation of the printed part. By heating the chamber, a more gradual temperature change can be achieved, which reduces thermal stress and improves the stability and reliability of printed parts.

3、Enhance Adhesion

For some filaments that are difficult to adhere to or where large models need to be printed, temperature controlled chambers can improve the adhesion of the substrate to the print platform. This helps prevent the substrate from peeling or distorting and improves print success.

4、Increase Print Speed

temperature controlled chambers accelerate the melting and curing process of the filament, thereby increasing print speeds. Higher temperatures increase the fluidity of the material, reducing the waiting time and speeding up the entire printing process.

5、Reduce Defects

Controlling a constant temperature can reduce the formation of defects such as bubbles, holes and non-adhesion between layers. This helps to obtain a more uniform and smooth print surface, reducing the need for subsequent processing.

*Note: Before picking up the model, please wait for the chamber temperature to slowly cool down to room temperature, which can effectively prevent the model from deformation due to rapid cooling and affect the accuracy.

In the end

In summary, QIDI Max3 and Plus3, equipped with temperature controlled chamber, have obvious advantages in print speed, print quality and support for the use of high-performance filaments. If you are considering getting a large-size and high-performance industrial-grade 3D printer, QIDI Max3 must be your best choice; If you don't have a big need for large prints, but still want a 3D printer with the same high performance and support for high-performance filaments, QIDI Plus3 is also a good choice.

For more information about QIDI printers and services, please browse our website. If you encounter any problems in using QIDI 3D printers, please contact QIDI after-sales service. We will sincerely and patiently solve the problem for you.

Q2

Q2

QIDI Box

QIDI Box

Plus 4

Plus 4

Q1 Pro

Q1 Pro

X-Max 3

X-Max 3