ما هي أقوى مادة طباعة ثلاثية الأبعاد؟

قوة الخاص بك مواد الطباعة ثلاثية الأبعاد يُعدّ فهم الخصائص الميكانيكية للخيوط المختلفة أمرًا بالغ الأهمية، سواءً كنت تُهندس مكونات صناعية، أو تُصمّم معدات واقية، أو تُصنّع نماذج أولية عملية. يُعدّ فهم الخصائص الميكانيكية للخيوط المختلفة أمرًا بالغ الأهمية لضمان متانة وأداء وسلامة إبداعاتك المطبوعة. في هذا الدليل، سنستكشف عالم أقوى مواد الطباعة ثلاثية الأبعاد، مما يُمكّنك من اختيار الحلول المثالية لتطبيقاتك الأكثر تطلبًا. بدءًا من تحديد المقاييس الرئيسية لقوة المواد ووصولًا إلى تسليط الضوء على التركيبات المتقدمة التي تتجاوز الحدود، ستكتسب الرؤى اللازمة للارتقاء بإمكانياتك في الطباعة ثلاثية الأبعاد.

أساسيات قوة مادة الطباعة ثلاثية الأبعاد

متى اختيار المواد لمشاريع الطباعة ثلاثية الأبعاد الخاصة بكإن فهم الجوانب المختلفة لقوة المواد أمر بالغ الأهمية.

1. قوة الشد: قياس مرونة المادة

قوة الشد هو أقصى إجهاد يمكن للمادة تحمله أثناء الشد أو السحب. تتميز الخيوط عالية الأداء، مثل خيوط PEEK، وألياف الكربون المركبة، والبولي كربونات، بهذه الخاصية المهمة، مما يجعلها مناسبة تمامًا للتطبيقات الصعبة.

2. الاستطالة والسحب: تقييم المرونة والتشوه

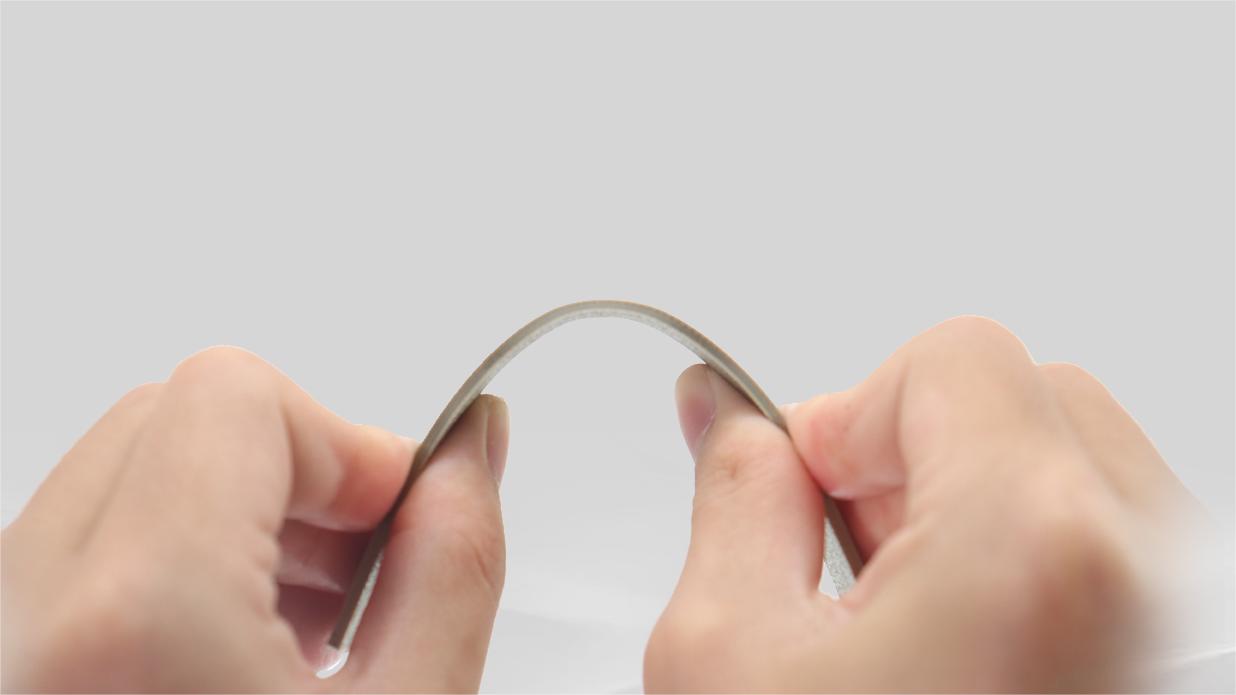

هناك عامل رئيسي آخر وهو قدرة المادة على التشوه تحت الضغط، وهو ما يعرف بالاستطالة أو اللدونة. المواد عالية اللدونة، مثل بعض المعادن، قد تتعرض لتشوهات كبيرة قبل الانهيار، مما يوفر مزيجًا من القوة والمرونة. على العكس، قد تكون الخيوط منخفضة اللدونة أكثر عرضة للكسور الهشة.

3. الصلابة: تقييم مقاومة التآكل والانبعاج

صلابة المادة، كما تُقاس بمقياس روكويل للمعادن أو مقياس ديوروميتر للبوليمرات، تلعب دورًا حاسمًا في مقاومة القطعة للتآكل والانبعاج. وهذا اعتبار مهم لـ متانة وطول عمر المكونات المطبوعة ثلاثية الأبعاد تعرض لمستويات عالية من الاحتكاك أو الإجهاد البدني.

4. مقاومة الصدمات: تحمل القوى المفاجئة

بالنسبة للتطبيقات التي قد يتعرض فيها الكائن المطبوع لصدمات أو تصادمات غير متوقعة، مثل معدات الحماية أو مكونات الآلات، فإن المواد مثل البولي كربونات والنايلون وPEEK تتفوق في مقاومة الصدمات.

5. مقاومة المواد الكيميائية والأشعة فوق البنفسجية: الحماية من أشعة الشمس

بالنسبة للأجزاء المطبوعة ثلاثية الأبعاد والمخصصة للبيئات الكيميائية القاسية أو للاستخدام الخارجي، تُصبح مقاومة هذه المواد للمواد الكيميائية والأشعة فوق البنفسجية أمرًا بالغ الأهمية. يوفر النايلون والبولي كربونات والبوليمرات المتقدمة مقاومة كيميائية استثنائية، بينما تتميز النايلونات المصنوعة من ABS وASA والأشعة فوق البنفسجية بقدرات فائقة على حجب الأشعة فوق البنفسجية.

6. مقاومة درجات الحرارة وHDT: تحمل درجات الحرارة العالية

قدرة المادة على تحمل درجات الحرارة المرتفعة، كما يتم قياسها من خلال درجة حرارة انحراف الحرارة (HDT)يُعدّ عامل مقاومة الحرارة العالية عاملاً حاسماً في التطبيقات عالية الحرارة. يُعدّ النايلون، والبيك، والبولي كربونات أمثلة على الخيوط ذات مقاومة الحرارة العالية.

مواد الطباعة ثلاثية الأبعاد الشائعة ونقاط قوتها

يقدم عالم الطباعة ثلاثية الأبعاد مجموعة متنوعة من مواد الخيوط، ولكل منها مزيج خاص من الخصائص الميكانيكية وخصائص الأداء.

1. البولي كربونات (PC): قوي ومقاوم للصدمات والحرارة

البولي كربونات عبارة عن مادة متينة للطباعة ثلاثية الأبعاد. فهو يقاوم الكسر عند تمدده، ولا يتحطم بسهولة عند الضرب، ويحافظ على شكله حتى عندما يكون ساخنًا.تجعل هذه الميزات هذه المادة رائعة للاستخدام في الأجزاء الصناعية ومكونات السيارات وغيرها من الاستخدامات حيث تكون المتانة مهمة.

2. أكريلونيتريل بوتادين ستايرين (ABS): قوي إلى حد ما ومتعدد الاستخدامات

نظام ABS هو نوع شائع من البلاستيك المستخدم في الطباعة ثلاثية الأبعاد. يتميز بمتانة جيدة ومقاومته للصدمات، مما يجعله مناسبًا للعديد من المشاريع المختلفة. مع أنه ليس بقوة البولي كربونات، إلا أن ABS مناسب لاختبار التصاميم الجديدة وتصنيع المنتجات الاستهلاكية.

3. حمض البولي لاكتيك (PLA): صلب، قوي، وصديق للبيئة

جيش التحرير الشعبى الصينى يُعرف بمتانته وصلابته وقابليته للتحلل الحيوي. كما أنه سهل الطباعة. مع ذلك، يلين PLA عند تعرضه للحرارة. وهو مثالي للمشاريع الصديقة للبيئة، والاستخدامات التعليمية، والأغراض التي لا تتطلب درجات حرارة عالية.

4. النايلون (PA): مرن، قوي، وممتص للصدمات

نايلونالنايلون، المعروف أيضًا باسم البولي أميد، يتميز بقدرته على امتصاص الصدمات، ومتانته مع مرونة طفيفة، ومقاومته للتآكل والتلف. هذه الصفات تجعله مثاليًا للنماذج التجريبية من المنتجات وقطع الآلات التي تتطلب قوة ومرونة طفيفة.

5. خيوط بيك وألياف الكربون: قوية للغاية ومقاومة للحرارة

نظرة خاطفة و تُعد مواد ألياف الكربون من أفضل المواد المستخدمة في الطباعة ثلاثية الأبعادتتميز هذه المواد بقوة استثنائية وقدرة على تحمل درجات حرارة عالية جدًا. تُستخدم هذه المواد المتطورة في تصنيع الأجزاء التي تتطلب حمل حمولات ثقيلة، ومكونات الطائرات، والأجهزة الطبية.

تتمتع كل هذه المواد بنقاط قوتها الخاصة، لذا فإن الاختيار الأفضل يعتمد على ما تصنعه وكيف سيتم استخدامه.

ما هي أقوى مادة للطباعة ثلاثية الأبعاد؟

تعتمد أقوى مادة للطباعة ثلاثية الأبعاد على المتطلبات المحددة لمشروعك. ومع ذلك، تحتل ثلاث مواد باستمرار مكانةً بارزةً بين أفضل المواد: النايلون المقوى بألياف الكربون، والبولي كربونات، والبولي إيثير إيميد (PEI). وتتميز كلٌّ منها بجوانب مختلفة من القوة والمتانة.

1. نايلون معزز بألياف الكربون: القوة والمرونة

يتميز النايلون المقوى بألياف الكربون بأنه مادة فائقة القوة. فهو يجمع بين قوة ألياف الكربون ومتانة النايلون، مما ينتج عنه منتج قوي ومقاوم للتآكل. غالبًا ما تُستخدم هذه المادة في مكونات الطائرات خفيفة الوزن والمتينة، وقطع غيار السيارات المقاومة للإجهاد، والأدوات الصناعية المتينة. ويتفوق أداؤها في كثير من الأحيان على الخيارات التقليدية في التطبيقات الصعبة.

2. البولي كربونات: متين بشكل استثنائي

البولي كربونات يشتهر البولي كربونات بمتانته ومقاومته للحرارة. فهو يحافظ على شكله وسلامته حتى في ظل الضغوط الشديدة أو درجات الحرارة المرتفعة. يُستخدم عادةً في معدات الحماية، مثل النظارات الواقية والخوذات، ومكونات الآلات عالية التحمل، وأغلفة الإلكترونيات المتينة. يتألق هذا المعدن في البيئات التي تتطلب حلولاً متينة وطويلة الأمد.

3. بولي إيثير إيميد (PEI): أداء متعدد الاستخدامات

بولي إيثير إيميد، المعروف باسم ألتيم، هو بلاستيك عالي الأداء. يتميز بمتانته وقدرته على تحمل الحرارة ومقاومته الكيميائية، مما يجعله قيّمًا في مختلف الصناعات. أثبت بولي إيثير إيميد جدارته في مكونات الطائرات الداخلية، وقطع غيار السيارات، والمعدات الطبية المقاومة للمواد الكيميائية. قدرته على الحفاظ على خصائصه في الظروف القاسية تجعله أساسيًا في المكونات الأساسية.

تختلف أقوى مواد الطباعة ثلاثية الأبعاد باختلاف الاحتياجات. ينبغي أن يُراعي اختيارك نوع الضغط الذي تتحمله القطعة، والظروف البيئية، ومتطلبات الوزن، وقيود الميزانية. يُساعد التقييم الدقيق لهذه الجوانب في تحديد المادة ذات مستوى القوة المناسب لمشروعك.إن القوة المثالية لا تعني دائمًا الاختيار الأفضل - إن العثور على التوازن الصحيح بين الخصائص لتطبيقك المحدد هو المفتاح.

اعتبارات عملية لاستخدام مواد الطباعة ثلاثية الأبعاد القوية

عند اختيار مواد قوية للطباعة ثلاثية الأبعاد، هناك العديد من العوامل الرئيسية التي يجب مراعاتها.

كم من الوقت سوف يستمر؟

يجب أن تدوم المواد القوية لفترة طويلةولكن عوامل مختلفة قد تؤثر على مدة صلاحيتها. فالماء يُضعف بعض المواد بمرور الوقت. ودرجات الحرارة العالية أو المنخفضة جدًا قد تُتلف أجزاؤها. وأشعة الشمس قد تجعل بعض المواد البلاستيكية هشة. وتؤثر المواد الكيميائية المختلفة على المواد بطرق مختلفة.

من المهم اختيار مادة مناسبة لمكان استخدام القطعة. فالقطعة التي تعمل جيدًا في الداخل قد لا تدوم طويلًا إذا استُخدمت في الخارج.

كم يكلف؟

المواد الأقوى تكلف في كثير من الأحيان أموالاً أكثر. عادةً ما تكون المواد الأساسية، مثل PLA، الأرخص. أما المواد متوسطة الجودة، مثل النايلون، فتُعدّ أغلى. أما المواد عالية الأداء، مثل PEEK، فهي الأغلى.

فكّر فيما إذا كنتَ بحاجةٍ فعلاً إلى مادةٍ أقوى. أحياناً، قد يكون استخدام مادةٍ أرخص مع تصميمٍ أفضل للقطعة مُجدياً بنفس القدر.

هل سيعمل مع الطابعة الخاصة بك؟

لا يمكن لجميع الطابعات استخدام كل أنواع المواد. تتطلب بعض المواد درجات حرارة عالية جدًا للطباعة. بينما تتطلب مواد أخرى أسطحًا خاصة للالتصاق بها أثناء الطباعة. بعض المواد تحتاج إلى تبريد أثناء الطباعة، بينما لا تحتاج مواد أخرى إلى ذلك.

قد تحتاج إلى ترقية طابعتك لاستخدام مواد متينة. قد يعني ذلك شراء قطع جديدة تتحمل درجات حرارة أعلى، أو تغيير السطح الذي تطبع عليه، أو إضافة غطاء للحفاظ على الحرارة، أو تحسين آلية تبريد طابعتك.

تأكد دائمًا من قدرة طابعتك على التعامل مع المواد المطلوبة. هذا يساعدك على الحصول على نتائج جيدة وتجنب تلف طابعتك.

بناء أقوى، طباعة أذكى

عند الحديث عن الطباعة ثلاثية الأبعاد، ليست القوة العامل الوحيد الذي يجب مراعاته. فبينما توفر مواد مثل النايلون المقوى بألياف الكربون، والبولي كربونات، وPEI قوةً هائلة، إلا أن اختيارك يجب أن يعتمد على احتياجات مشروعك الخاصة. فكّر في مكان استخدام القطعة، ومدة استمرارها، وميزانيتك. لا تنسَ التحقق من قدرة طابعتك على التعامل مع المواد التي ترغب في استخدامها. قد تحتاج إلى ترقية طابعتك لاستخدام مواد عالية الأداء. بتقييم هذه العوامل بعناية، ستتمكن من إنشاء قطع مطبوعة ثلاثية الأبعاد ليست قوية فحسب، بل متينة أيضًا واقتصادية. استخدم هذا الدليل لاتخاذ قرارات مدروسة لمشروع الطباعة ثلاثية الأبعاد القادم.

الأسئلة الشائعة حول مواد الطباعة ثلاثية الأبعاد

1. ما هي المادة الأقوى من الطباعة ثلاثية الأبعاد PLA؟

العديد من المواد أقوى من PLA. ABS أقوى وأكثر مقاومة للحرارة. النايلون أكثر صلابة ومرونة. للحصول على أعلى قوة، يُنصح باستخدام النايلون المقوى بألياف الكربون، أو البولي كربونات، أو PEEK. تتميز هذه المواد بمتانة ومقاومة أفضل للحرارة من PLA.

2. ما هي أفضل المواد التي يمكن استخدامها للطباعة ثلاثية الأبعاد؟

لا توجد مادة واحدة "أفضل" - فالأمر يعتمد على احتياجاتك. لسهولة الطباعة وتكلفة منخفضة، يُعدّ PLA خيارًا ممتازًا. أما ABS أو PETG، فهما خياران ممتازان للقوة ومقاومة الحرارة. إذا كنت بحاجة إلى خيارات أقوى، فابحث عن مركبات البولي كربونات أو ألياف الكربون. عند الاختيار، ضع في اعتبارك الخصائص الأكثر أهمية لمشروعك.

3. ما هي المادة الأكثر متانة للطباعة ثلاثية الأبعاد؟

المواد الأكثر قوة عادة ما تكون عبارة عن مواد مركبة مثل النايلون المقوى بألياف الكربون، أو البلاستيك عالي الأداء مثل PEEK أو PEI (Ultem).تتميز هذه المواد بقوة ممتازة، ومقاومة للحرارة، ومتانة فائقة. تُستخدم غالبًا في تطبيقات الطيران والفضاء أو التطبيقات الصناعية حيث لا يكون الفشل خيارًا.

4. ما هي المادة الأرخص للطباعة ثلاثية الأبعاد؟

عادةً ما يكون PLA أرخص مادة للطباعة ثلاثية الأبعاد. فهو سهل الطباعة ومتوفر على نطاق واسع. كما أن ABS رخيص نسبيًا. مع ذلك، تجدر الإشارة إلى أنه على الرغم من رخص هذه المواد، إلا أنها قد لا تكون مناسبة لجميع المشاريع نظرًا لمتانتها ومقاومتها للحرارة المحدودة.

5. ما هو أقوى نمط للطباعة ثلاثية الأبعاد؟

عادةً ما يكون النمط الأقوى هو حشوة شبكية بكثافة ٥٠-١٠٠٪. كما أن الأنماط المثلثية أو الشبيهة بخلايا النحل قوية جدًا. بالنسبة للجدران الخارجية، فإن زيادة المحيطات (٣-٤) تزيد من المتانة. كما أن طباعة طبقات أكثر سمكًا قد يكون مفيدًا. تذكر أن النمط الأمثل يعتمد على القطعة المحددة وكيفية استخدامها.

س 2

س 2