What Are the Differences Between Industrial and Home 3D Printers?

Table of Contents

In the rapidly evolving world of 3D printing, understanding the distinctions between industrial and home 3D printers is crucial for making informed decisions. Whether you're a seasoned professional or a curious hobbyist, this blog post will guide you through the key differences between these two categories of additive manufacturing machines.

A Quick Look Sheet:| Feature | Industrial 3D Printers | Home 3D Printers |

|---|---|---|

| Build Volume | Typically starting from 500 x 500 x 500 mm | Range from 150 x 150 x 150 mm to 300 x 300 x 300 mm |

| Print Quality and Precision | Layer resolutions between 0.1 to 0.3 mm | Layer resolutions between 0.1 to 0.3 mm (may require post-processing for smoothness) |

| Materials Compatibility | Wide range including PLA, ABS, PETG, TPU, Nylon | Mainly PLA, ABS; others depending on printer capabilities |

| Speed and Production Time | Fast production with larger nozzles and multiple print heads | Slower, suitable for hobbyist projects where time isn't critical |

| Software and User Interface | Complex software requiring operator training | User-friendly interfaces approachable for beginners |

| Price and Cost of Ownership | Tens of thousands of dollars plus maintenance costs | Affordable, starting at a few hundred dollars with minimal upkeep costs |

| Maintenance and Durability | Built for continuous use with comprehensive service plans | Easier maintenance but may not endure heavy continuous use |

| Use Cases and Applications | Professional applications in automotive, aerospace, product design | Hobbyists, educators, and personal projects |

What Are Industrial 3D Printers?

Industrial 3D printers are high-performance machines designed for demanding professional applications. These printers offer large build volumes, exceptional print quality, and compatibility with a wide range of materials. They are built to handle continuous, high-volume production and are essential tools in industries such as automotive, aerospace, and product design.

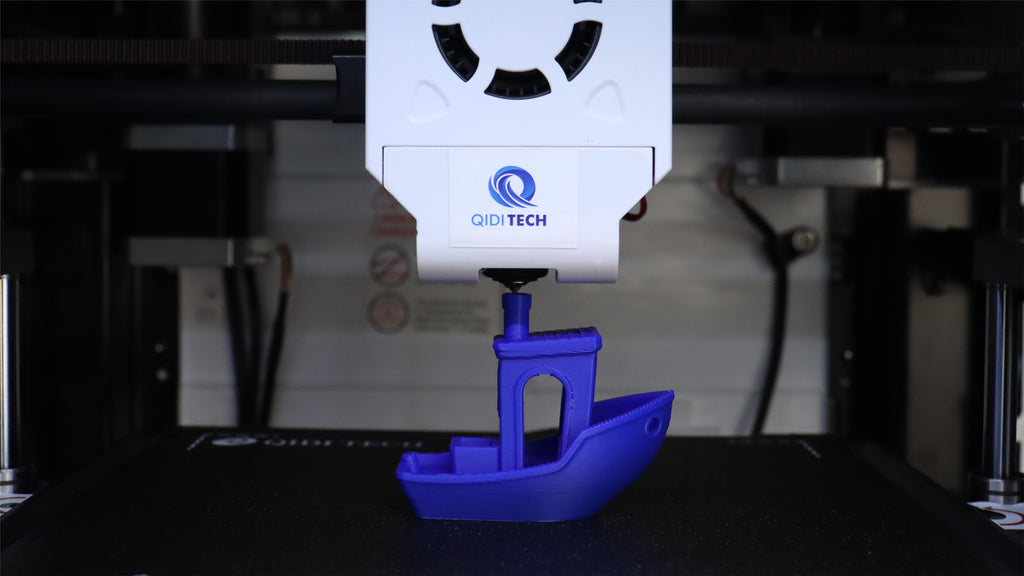

What Are Home 3D Printers?

Home 3D printers are compact, desktop machines that are perfect for hobbyists, educators, and enthusiasts. These printers offer an accessible and affordable entry point into the world of 3D printing, allowing users to bring their creative ideas to life or explore the technology for personal projects and learning experiences.

Differences Between Industrial and Home 3D Printers

Build Volume and Physical Size

One of the most striking differences between industrial and home 3D printers is their build volume – the maximum size of objects they can create. Industrial 3D printers boast expansive build spaces typically starting from 500 x 500 x 500 millimeters (20 x 20 x 20 inches). These machines can effortlessly handle large-scale projects, such as full-size prototypes and sizable components.

On the other hand, home 3D printers offer build volumes ranging from 150 x 150 x 150 millimeters to 300 x 300 x 300 millimeters. These desktop machines are perfect for crafting smaller items like toys, jewelry, and smartphone cases, fitting comfortably in your living space. Notably, QiDi Tech's X-Max 3 3D printers stand out from the crowd with an impressive build volume of 325 x 325 x 315 millimeters, providing ample room for more ambitious home projects.

Print Quality and Precision

Print quality and precision are crucial factors when comparing industrial and home 3D printers. Industrial 3D printers are capable of producing exceptionally detailed prints with layer resolutions typically ranging from 0.1 to 0.3 millimeters. This level of precision is ideal for creating intricate designs, functional prototypes, and end-use parts that require a high degree of accuracy.

Home 3D printers, while not quite as precise as their industrial counterparts, still offer impressive print quality. Most desktop machines can achieve layer resolutions between 0.1 and 0.3 millimeters, making them suitable for a wide range of projects. However, you may notice visible layer lines and may need to perform some post-processing, such as sanding, to achieve a smooth finish.

Materials and Compatibility

Both industrial and home 3D printers typically use filaments such as:

-

PLA (Polylactic Acid): This eco-friendly, easy-to-print material is perfect for beginners and is ideal for creating decorative objects and low-stress items.

-

ABS (Acrylonitrile Butadiene Styrene): Known for its durability, ABS is a popular choice for creating objects that may be subjected to wear and tear, such as toys and basic tools.

-

Other filaments: 3D printers can also work with a variety of specialized materials, including PETG, TPU, and Nylon, each with unique properties and applications.

When choosing a 3D printer, consider the types of materials you'll be working with. For simple projects like keychains or small figurines, a home 3D printer with PLA filament will suffice. However, for more demanding applications, both industrial and home 3D printers offer a wide range of material options to suit your needs.

Speed and Production Time

Speed is another critical factor when comparing industrial and home 3D printers. Industrial 3D printers are designed for rapid, high-volume production. Thanks to advanced features like larger nozzles and multiple print heads, these machines can churn out prototypes and parts in a matter of hours. For businesses, this increased speed translates to faster product development cycles and quicker time-to-market.

Home 3D printers typically take longer to print objects, with smaller items potentially requiring several hours to complete. However, this slower pace is perfectly suitable for hobbyists and small projects where time is not of the essence.

To illustrate the difference in speed, consider the example of printing a chess piece. A home 3D printer might take an hour to print a single piece, while an industrial machine could potentially print the entire set in the same amount of time. This speed advantage is crucial for time-sensitive commercial production runs.

If you need to rapidly produce large quantities of parts or prototypes, an industrial machine is the way to go. For casual home use and smaller projects, a desktop 3D printer will suffice. If you require both capabilities, opting for advanced home 3D printers like the Qidi Tech X-Plus 3 can achieve print speeds comparable to those of industrial-grade 3D printers, reaching up to 600mm/s.

Software and User Interface

The software and user interface of a 3D printer can greatly impact the overall user experience.

Industrial 3D printers often feature complex software and specialized controls. These machines may require operator training to navigate the advanced settings and fine-tune the printing process for optimal results.

On the other hand, home 3D printers typically offer user-friendly interfaces that are more approachable for beginners. The software for these machines is often straightforward, featuring intuitive menus and drag-and-drop functionality, making them accessible to hobbyists, students, and educators.

If you're a seasoned professional working on advanced applications, the sophisticated controls of an industrial machine may be a perfect fit. However, for those new to 3D printing or working on simpler projects, the user-friendly interface of a home 3D printer may be more suitable.

Price and Cost of Ownership

Home 3D printers are affordable, with prices starting at just a few hundred dollars. These machines are perfect for hobbyists and those looking to dip their toes into the world of 3D printing without breaking the bank.

Industrial 3D printers can easily cost tens of thousands of dollars, with some models even reaching six-figure price tags. In addition to the initial investment, industrial 3D printers also come with ongoing costs for maintenance and materials.

Maintenance and Durability

Industrial 3D printers are built to withstand the rigors of continuous, high-volume production. These machines are engineered to operate around the clock and often come with comprehensive warranty and service plans to keep them running smoothly for years to come.

Home 3D printers, while not as robust as their industrial counterparts, are generally easy to maintain and troubleshoot. However, these desktop machines may not be able to handle the same level of continuous, heavy use as industrial printers without experiencing wear and tear over time.

Use Cases and Applications

Industrial 3D printers are essential tools in industries where consistency, precision, and durability are paramount, such as automotive, aerospace, and product design.

Home 3D printers are perfect for hobbyists, educators, and enthusiasts looking to bring their creative ideas to life or explore the exciting world of 3D printing technology. From custom toys and figurines to household items and educational models, home 3D printers offer endless possibilities for personal projects and learning experiences.

Conclusion

The differences between industrial and home 3D printers are significant, each category catering to distinct needs and applications. Industrial 3D printers offer unparalleled precision, speed, and durability for demanding professional projects, while home 3D printers provide an accessible and affordable entry point for hobbyists, learners, and creative enthusiasts.

By understanding the key factors that set these two types of machines apart, you can make an informed decision when choosing the right 3D printer for your needs. Whether you're a seasoned professional or a curious beginner, there's a 3D printer out there that's perfect for you.