3D Printer Maintenance Costs and Ways to Reduce Them

Table of Contents

While 3D printers allow you to create all sorts of objects right at home, the costs of keeping them running smoothly over time is something to think about. Proper maintenance is key for getting the most life and best performance out of your 3D printer. In this article, we'll look at the different things that affect how much it costs to maintain a 3D printer - like the materials you use, parts that wear out and need replacing, professional repair services if needed, electricity usage, and tips on taking good care of your printer to reduce expenses. Getting the upfront and ongoing maintenance costs right is important for 3D printing to make financial sense long-term.

Cost of Getting Started with 3D Printing

How Much Do 3D Printers Cost Initially?

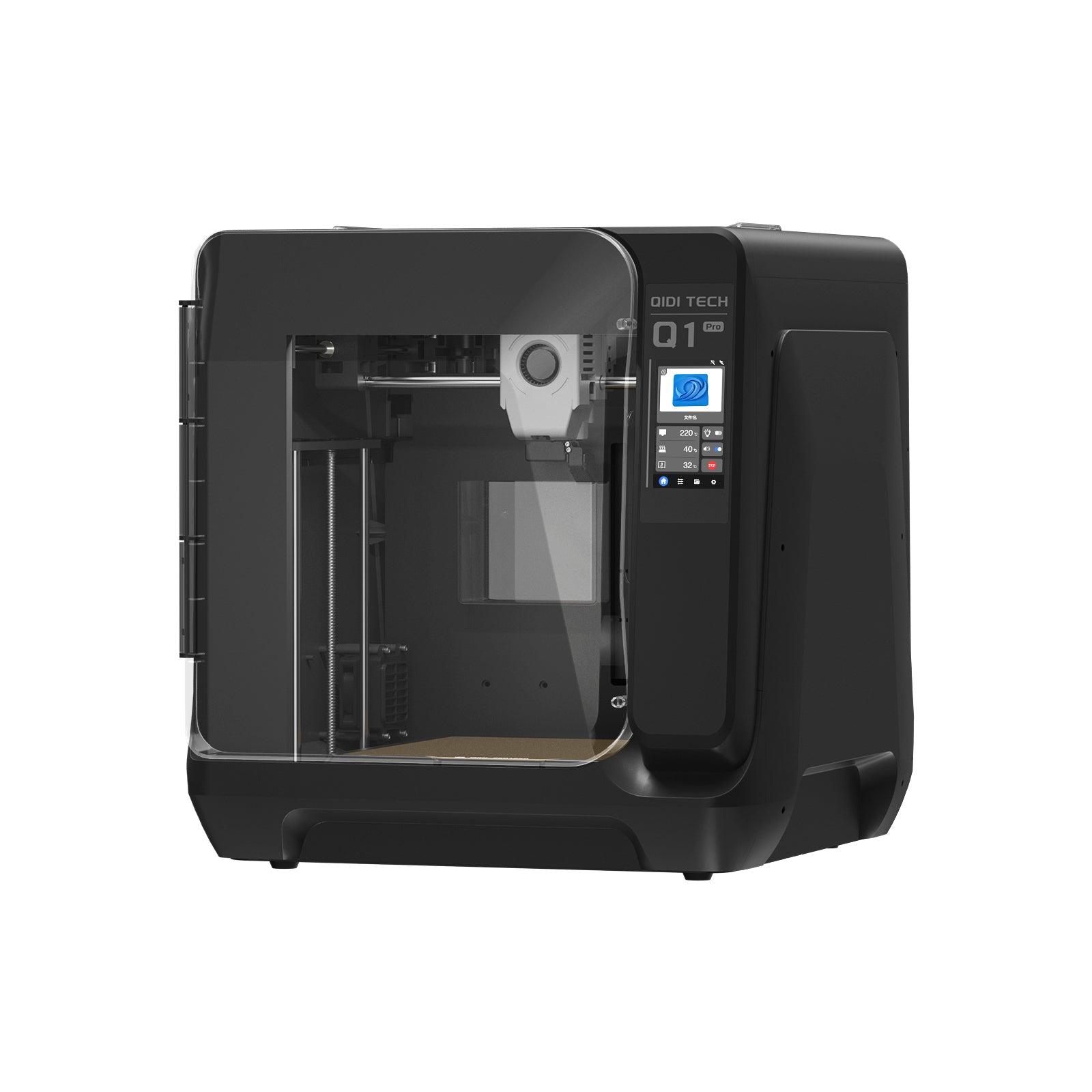

One of the biggest factors in the overall maintenance costs of 3D printing is the upfront price of purchasing the 3D printer itself. Entry-level 3D printers can be relatively affordable, with some desktop models available for $200-$300. However, these budget options tend to have smaller build volumes and more basic feature sets.

For hobbyists or those wanting more printing capabilities, you'll likely need to spend $500-$1,500 on a more advanced 3D printer.

The most high-end professional 3D printers can cost $2,000 or more. These are designed for industrial/commercial use with premium components, massive build volumes, high precision, and fast print speeds. About this topic, read this guide to learn more: What Is the Difference Between Hobby and Commercial 3D Printers?

Build Volume Impacts Cost

As a general rule, 3D printers with larger build volumes capable of printing bigger objects will cost more than those with smaller build areas. The build volume is one of the key specifications to consider based on your intended uses.

Brand Reputation Factors In

Like most product categories, you'll pay a premium for 3D printers from established, reputable brands versus off-brand or white-label printers with similar capabilities. The higher pricing gets you better customer support, perceived quality, and brand recognition.

So in summary, budget around $200-$500 for an affordable entry-level 3D printer, $500-$1,500 for an enthusiast-level model, and $2,000+ for high-end professional and commercial 3D printers. Consider your needs, budget and recognize you'll get what you pay for in terms of build volume, features and brand.

Ongoing Costs of 3D Printing Materials

Filament and Resin - The Print Materials

To actually print 3D objects, you'll need a continuous supply of the raw print materials. These come in two main forms:

- Filament: Filament is the solid plastic material that gets melted and extruded for FDM (fused deposition modeling) 3D printers. It comes on spools in different material types like PLA, PETG, ABS, etc. Common filament sizes are 1.75mm and 2.85mm diameter.

- Resin: Resin is the liquid photopolymer material used in SLA (stereolithography) and DLP (digital light processing) 3D printers. The resin gets cured and hardened by UV light layer-by-layer.

Average Filament and Resin Costs

On average, a 1kg spool of filament ranges from $30-$60 depending on the material type and brand. Resins typically cost $30-$100 per liter bottle.

Buy in Bulk for Lower Cost per Weight

Most filament makers offer discounts if you purchase multi-packs or larger spools over 1kg. For example, QIDI Tech offers a range of high-performance filaments with attractive bulk discounts. When you buy 2 spools, you get a 15% discount; buying 3 spools gets you a 20% discount; and if you purchase 4 or more spools, you can save 25% on your order. For their common materials, the savings are even greater: buying 2 spools gets you a 20% discount, 3 spools come with a 30% discount, and purchasing 4 or more spools will save you 35% off the regular price. These bulk discounts significantly reduce the average cost per kilogram of filament.

Cost of Replacing Worn Out 3D Printers Parts

Parts That Need Switching Out Eventually

No matter how well you take care of your 3D printer, certain parts are going to wear down and need replacing after a lot of use:

- Print Beds: The flat surface where objects are printed can get scratched up, dented or warped from all the heating and cooling. Swapping in a new print bed helps objects stick properly again.

- Nozzles: The tiny nozzle that squeezes out the melted plastic can get clogged or worn down, making prints look messy. Replacing it with a fresh nozzle fixes print quality.

- Fans: The little fans that blow air to keep things cool are prone to breaking down over time. Replacing busted fans prevents heat issues.

- Belts/Pulleys: The rubber belts and plastic pulleys that move the printer arms back and forth can slip or break after thousands of hours printing.

Replacement Part Costs

You can usually get a new print bed for $20-$50 depending on the size. Packs of nozzles are $10-$30. Replacement fans are $5-$20 each. New belts run $5-$15 per axis they move.

While it may be tempting to opt for cheaper, third-party replacement parts, it is highly recommended to purchase original parts directly from your 3D printer's manufacturer. These parts are specifically designed and tested to work seamlessly with your printer model, ensuring optimal performance and longevity. Additionally, using original parts helps maintain your printer's warranty and reduces the risk of compatibility issues or further damage to your machine.

Professional 3D Printing Maintenance Services

When to Use a Repair Service

As some 3D printer issues can be resolved through DIY troubleshooting, there may be times when professional repair service is needed:

Major Hardware Failures

If critical components like the control board, motors, or heated build plate fail, you'll likely need expert repair unless you're very technically savvy.

Software/Firmware Issues

Problems with slicing software, firmware updates, or getting prints to initiate properly may require professional assistance.

Post-Purchase Setup

Many opt to have a 3D printer professionally set up and calibrated properly out of the box to ensure optimal performance from the start.

Typical Service Costs

Depending on the issue, professional 3D printer repair services typically charge $100-$300 for labor plus any parts needed. More complex repairs can run up to $500 or more.

Some 3D printer manufacturers, like QIDI Tech, have their own professional after-sales teams that can help troubleshoot and resolve machine issues reported by customers within the warranty period.

DIY Repairs to Save Costs

Those comfortable working on electronics and mechanicals can attempt many 3D printer repairs themselves by sourcing guides and replacement parts online to reduce or avoid service fees.

Overall, having a quality 3D printer repaired by a professional is sometimes the best way to quickly get it back up and running properly.

Tips for Affordable 3D Printers Maintenance

Proper Printer Care and Handling

The way you treat and handle your 3D printer makes a big difference in keeping maintenance costs down. Taking good care of it from the start is key - keep it clean by wiping away any dust or debris regularly. Handle it gently and avoid dropping or bumping it. Follow all the manufacturer's guidelines for proper setup and operation. And only use the approved materials and settings recommended for your printer model.

Have a Preventive Maintenance Routine

A little routine maintenance here and there goes a long way. Every so often, check the fans and vents for clogs and give the nozzle a cleaning. Tighten any loose screws, pulleys or belts that may have come loose. If any moving parts are getting noisy, put a dab of lubricant on them. Don't forget to update the printer's firmware and slicing software when new versions come out too.

Learn to Troubleshoot Common Issues

Many common 3D printing problems like poor layer adhesion, stringy prints, layers becoming misaligned and more can usually be fixed through basic troubleshooting. Start by checking that the build plate is properly leveled and calibrated. Then experiment with adjusting temperatures, print speeds, retraction settings and trying different materials until it prints smoothly. There are lots of guides online with solutions for specific issues.

Buy Quality Materials and Parts

While you can find off-brand supplies for less money, sticking with quality materials and parts from reputable brands pays off. You'll get much more reliable, consistent print results. And the components will likely last longer before needing replacement. Most quality brands also offer better warranties and customer support too. So prioritizing quality over rock-bottom pricing on things like filament and nozzles ensures higher 3D printing success and lower maintenance costs longterm.

Maximize Your 3D Printing Investment Through Proper Upkeep

Home 3D printing is amazing, but the costs of materials, replacements, repairs, and electricity can really add up. Routinely maintaining your printer through cleaning, minor upkeep, and troubleshooting issues pays off big time. Investing in quality brand name supplies means more reliable prints and fewer headaches long-term. If you budget realistically for both the upfront and ongoing maintenance expenses, 3D printing remains an affordable hobby or business. Don't cut corners - follow best practices to maximize your 3D printer's longevity.