How to Fix Warping in 3D Printing

Table of Contents

One of the most common challenges faced by 3D printing enthusiasts and professionals is the issue of warping. Warping happens when parts of a 3D printed object lift, curl, or deform during the printing process, leaving you with an uneven and distorted final product. This article will help you understand what causes warping in 3D printing, how different printing materials can impact it, and most importantly, give you practical tips and tricks to fix and prevent this annoying problem.

What Causes Warping in 3D Printing?

Warping in 3D printing can happen for a bunch of different reasons, but one of the biggest culprits is when the temperature isn't spread out evenly across the printed object. Let's break down some of the main things that can cause warping:

1. Uneven Print Bed Heating

If your print bed isn't heated evenly, it can make the bottom layers of your object cool and shrink at different speeds. This is a big problem for larger prints that take up more space on the bed.

2. Printing Too Fast

When you print at high speeds, the layers of your object might cool down too quickly before they have time to stick to the layers underneath. This can cause warping, especially at the corners and edges of your print.

3. Where You Put Your Printer Matters

If your 3D printer is in a spot with drafts, temperature changes, or direct sunlight, it can mess with the consistency of the printing environment. These outside factors can lead to uneven cooling and warping.

4. Wrong Slicer Settings

Your slicer software takes your 3D model and tells your printer what to do. If the settings in your slicer are wrong, like having the nozzle temperature too high or the layer height too thick, it can add to the warping problem.

5. Dirty Print Bed

A print bed that's not clean or has leftover bits from previous prints can stop your object from sticking properly. This poor sticking can cause the edges of your print to lift and warp over time.

How Do Different 3D Printing Materials Affect Warping?

The type of material you use for your 3D printing project can have a big impact on how likely it is to warp. Let's take a look at some of the most common materials and how they stack up:

ABS vs. PLA vs. HIPS

- ABS (Acrylonitrile Butadiene Styrene) is known for being strong and tough, but it's also more prone to warping because it requires higher printing temperatures and is more sensitive to temperature changes.

- PLA (Polylactic Acid) is a biodegradable material that's easier to work with and less likely to warp, thanks to its lower printing temperature and less sensitivity to temperature fluctuations.

- HIPS (High Impact Polystyrene) is similar to ABS in terms of strength and warping potential, but it's often used as a support material for ABS prints.

How Material Properties Influence Warping

The properties of each material can affect warping in different ways:

- Glass transition temperature: This is the temperature at which the material starts to soften and become more flexible. Materials with higher glass transition temperatures, like ABS, are more prone to warping.

- Thermal expansion: Some materials expand more than others when heated, which can lead to warping if the expansion is uneven. ABS has a higher thermal expansion rate than PLA, making it more susceptible to warping.

- Adhesion: How well the material sticks to the print bed can also play a role in warping. Materials with poor adhesion, like ABS, are more likely to warp than those with better adhesion, like PLA.

By understanding the characteristics of different printing materials, you can choose the one that's best suited for your project and less likely to give you warping headaches.

How to Fix Warping in 3D Printing

Now that you know what causes warping and how different materials can affect it, let's dive into some practical solutions to help you fix and prevent this annoying issue.

1. Use a Heated Print Bed

One of the best ways to combat warping is to use a heated print bed. By preheating your bed before starting a print, you can help the first layer of your object stick better and reduce the risk of warping. To take it a step further, you can also insulate your bed by covering the underside with insulation tape. This will help distribute the heat more evenly and keep a consistent temperature throughout the printing process.

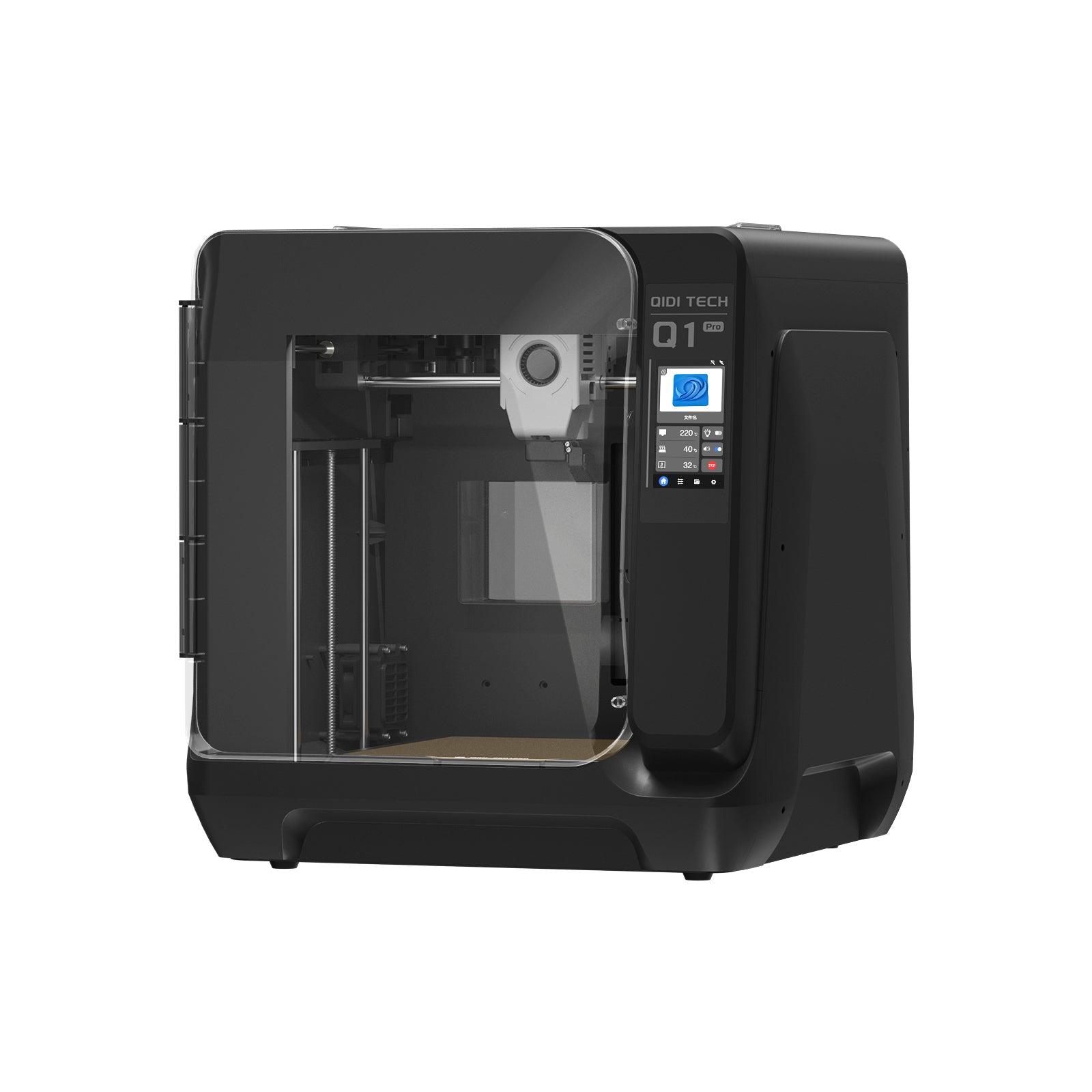

2. Create an Enclosed Print Chamber

Another effective method to reduce warping is to create an enclosed print chamber. This helps maintain a stable temperature around your object, preventing drafts and uneven cooling that can cause warping. By keeping the hot air inside the chamber, you minimize the risk of temperature changes that can lead to warping.

3. Find the Right Spot for Your Printer

Where you place your 3D printer can also have a big impact on warping. Try to keep your printer away from windows, doors, or air vents that can create drafts and uneven cooling. Instead, choose a location with a consistent temperature and humidity level to help minimize the risk of warping.

4. Tweak Your Cooling Settings

Believe it or not, Cooling fans can contribute to warping if they're running too fast. By reducing the speed of your cooling fans, especially during the first few layers of your print, you can help prevent the material from cooling too quickly and warping.

5. Improve Bed Adhesion

Getting your 3D printed object to stick to the print bed is crucial for avoiding warping. You can try using adhesives like glue, hairspray, or specialized bed adhesives to help your object stay put. Different materials also work better with different bed surfaces. For example, PLA tends to stick well to a heated glass bed, while ABS likes a bed covered with Kapton tape or something similar. You can also experiment with using a removable, flexible build plate, which can make it easier to take your object off the bed after printing without causing warping.

6. Fine-Tune Your Slicer Settings

Your slicer software settings can also play a role in preventing warping. Try printing at a slower speed to give each layer more time to cool and bond properly. You can also slightly lower the nozzle temperature to help prevent the material from overheating and warping, especially when using ABS. Another trick is to add rafts and brims to your design. These extra structures around the base of your object can help improve bed adhesion and minimize warping.

7. Keep Your Print Bed Clean

Make sure to regularly clean your print bed, removing any dirt, dust, or leftover material that could get in the way of proper adhesion. If your print bed gets scratched, warped, or uneven, you might need to replace it to ensure a flat and stable surface for your prints.

8. Invest in Quality Filament

Finally, using high-quality filament from trusted brands can make a big difference in reducing warping. Cheap, low-quality filament is more likely to have inconsistencies that can cause issues like warping. Each type of filament also has its own recommended settings for things like temperature and bed preparation, so be sure to follow these guidelines for the best results.

Say Goodbye to Warping in 3D Printing

Warping can be caused by various factors, including uneven bed heating, fast printing speeds, incorrect printer placement, poor slicer settings, and a dirty print bed. The filament type also influences warping, with some materials being more susceptible than others. Solutions like a heated bed, enclosed print chamber, optimized printer location, adjusted cooling settings, improved bed adhesion, fine-tuned slicer settings, regular print bed cleaning, and high-quality filament can help you minimize warping and achieve stunning results. Try implementing these techniques today and take your 3D printing to the next level!