Is an Open or Enclosed 3D Printer Better?

Table of Contents

3D printing has opened up a world of possibilities for creators, hobbyists, and innovators alike. As you dive into this exciting realm, you'll soon face an important decision: should you go for an open or enclosed 3D printer? This choice isn't just about looks-it can significantly affect your printing experience, from the quality of your finished pieces to how easily you can use and maintain your machine. Whether you're looking to craft custom figurines, prototype a new gadget, or bring your artistic visions to life, understanding the pros and cons of each printer type is crucial. Let's break down the differences between open and enclosed 3D printers, helping you find the perfect match for your creative journey.

A Quick Comparison Sheet about Open vs Enclosed 3D Printers

| Feature | Open 3D Printers | Enclosed 3D Printers |

|---|---|---|

| Accessibility | Easy access for modifications and maintenance | Limited access due to enclosure |

| Cost | Generally lower upfront cost | Higher initial investment |

| Print Quality | More vulnerable to environmental factors | Better consistency with controlled environment |

| Noise and Odor | Can be noisy and emit odors | Reduced noise and odor with enclosure |

| Material Versatility | Suitable for basic materials like PLA | Supports a wider range of materials |

Open vs Enclosed 3D Printers: Understanding the Basics

When you're shopping for a 3D printer, you'll encounter two main designs: open and enclosed.

Open 3D Printers: The Accessible Option

Open 3D printers have an exposed build area. Picture a printer where you can see all the moving parts in action. There's no box or cover around the printing mechanism, giving you a clear view of your object taking shape.

These printers are usually simpler in design, which often makes them more affordable and easier to tinker with. They're great for those who like to watch the printing process or make quick adjustments on the fly.

Open printers are popular in home workshops, schools, and small design studios. They're ideal for hobbyists who enjoy hands-on learning and don't mind a bit of noise. You'll often see them in makerspaces where users collaborate on projects.

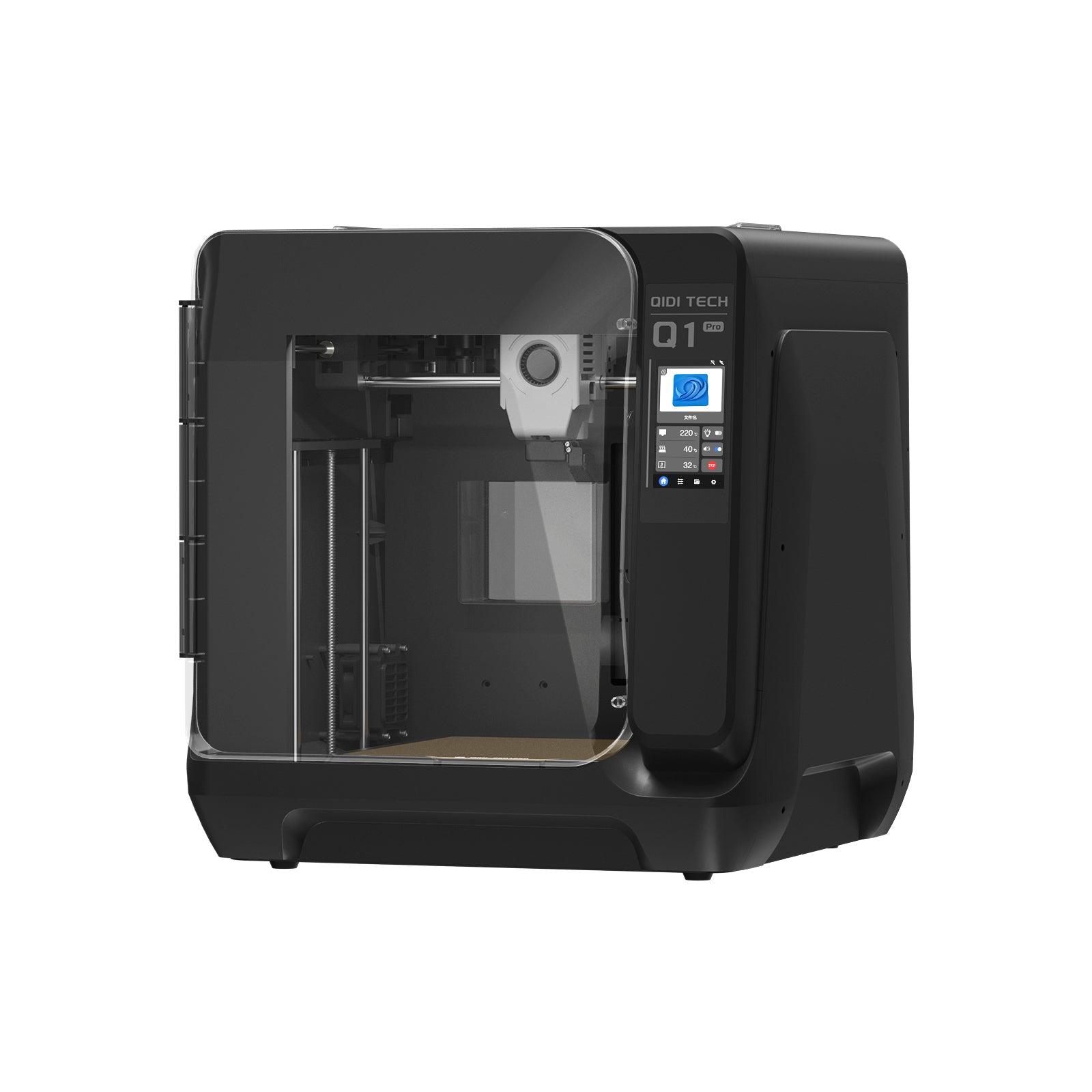

Enclosed 3D Printers: The Controlled Environment

Enclosed 3D printers, as the name suggests, have their printing mechanism housed within a box or cabinet. Think of it as a mini-workshop contained in a protective shell. These printers offer a controlled environment for your prints, which can be crucial for certain projects.

While typically more expensive, enclosed printers often come with features like temperature control and air filtration. They're designed to provide consistent printing conditions, which can lead to better print quality, especially for more demanding materials.

You're more likely to encounter enclosed printers in professional settings. They're common in manufacturing facilities, high-end design firms, and industries like aerospace or medical device production. These printers are favored where precision and environmental control are paramount.

Open 3D Printers: A Comprehensive Look

Open 3D printers have carved out a significant niche in the maker community.

1. Accessibility: Clear View and Easy Adjustments

The hallmark of open 3D printers is their accessibility. Without an enclosure, you have a clear view of the printing process and easy access to all components. This transparency is invaluable for learning and troubleshooting.

You can watch your creations take shape in real-time, which is not just fascinating but also practical. If something goes awry, you can quickly intervene, pausing the print or making adjustments on the spot. For beginners, this hands-on experience accelerates the learning curve, making it easier to understand the intricacies of 3D printing.

2. Cost: Lower Upfront Price, Potential Long-Term Tradeoffs

When it comes to price, open 3D printers often have an edge. Their simpler design typically translates to a lower initial cost, making them an attractive option for those just dipping their toes into 3D printing. The accessible design also means that upgrades and repairs are often more affordable and easier to perform yourself.

However, it's important to look beyond the sticker price. The lack of environmental control in open printers can lead to more failed prints, potentially increasing material waste over time. Consider both the upfront cost and potential long-term expenses when making your decision.

3. Print Quality: Vulnerability to Air and Temperature

The open design that makes these printers so accessible can also affect print quality. Without an enclosure, your prints are more susceptible to environmental factors. Temperature fluctuations in your workspace can lead to inconsistent print quality. Drafts can cause uneven cooling, potentially resulting in warped prints or poor layer adhesion.

On the flip side, the open design allows for better heat dissipation, which can be beneficial when working with certain materials. It's a trade-off between environmental control and flexibility that you'll need to weigh based on your specific printing needs.

4. Maintenance and Upgrades: Easy Access, More Frequent Care

For those who enjoy DIY projects, open 3D printers are a dream come true. The exposed components make regular maintenance straightforward. Cleaning is easier when you can reach all parts of the printer without hassle.

Moreover, the open design lends itself well to modifications and upgrades. You can easily swap out parts or add enhancements, allowing your printer to grow with your skills and needs.

However, this accessibility comes with added responsibility. Exposed components may require more frequent cleaning and care. You might also find yourself needing to recalibrate the printer more often due to its exposure to external factors.

Enclosed 3D Printers: The Complete Picture

Enclosed 3D printers offer a different approach to additive manufacturing.

1. Controlled Environment: Consistency and Quality

The defining feature of enclosed 3D printers is their sealed printing chamber. This enclosure creates a controlled environment, shielding the printing process from external factors.

Temperature stability is a major advantage. The enclosure maintains a consistent ambient temperature, which is crucial for certain materials like ABS that are prone to warping. This controlled environment often results in more reliable prints with better layer adhesion and fewer defects.

2. Safety and Emissions: A Cleaner Printing Experience

Enclosed printers excel in containing fumes and particles generated during printing. This is particularly important when working with materials that emit potentially harmful vapors.

Many enclosed models come with built-in filtration systems, making them a safer choice for home use or in spaces with limited ventilation. The enclosure also significantly reduces the noise level, creating a more pleasant printing environment.

3. Material Versatility: Expanding Your Printing Possibilities

The controlled environment of enclosed printers opens up possibilities for working with a wider range of materials. Temperature-sensitive filaments like ABS, Nylon, and even some exotic composites print more reliably in these conditions.

This versatility can be a game-changer for users who want to experiment with different materials or need specific material properties for their projects. However, it's worth noting that this advantage comes with a learning curve as you navigate the settings for various materials.

4. Cost and Complexity: Higher Investment, Greater Capabilities

Enclosed 3D printers generally come with a higher price tag than their open counterparts. The additional components like the enclosure, temperature control systems, and filtration add to the cost.

While the initial investment is higher, enclosed printers can be more cost-effective in the long run for certain users. The improved print reliability can result in less material waste and fewer failed prints, potentially offsetting the higher upfront cost over time.

5. Maintenance and Upgrades: Challenges and Considerations

Maintaining an enclosed printer can be more complex. The enclosure, while beneficial for printing, can make access for cleaning and repairs more challenging. Some models are designed with removable panels or doors to mitigate this issue.

Upgrading enclosed printers can also be more complicated and potentially more expensive. The integrated nature of these systems often means that modifications need to be carefully considered to maintain the benefits of the enclosed design.

Is an Open or Enclosed 3D Printer Better?

The short answer is: it depends on your specific needs, budget, and intended use. Both open and enclosed 3D printers have their strengths, and the "better" choice varies based on individual circumstances.

1. User Experience and Skill Level

For beginners, open printers offer a more hands-on learning experience. You can observe the printing process up close, gaining a deeper understanding of 3D printing mechanics. This transparency can be invaluable for troubleshooting and honing your skills.

Enclosed printers, while potentially more complex, offer a more forgiving environment for first-time users. The controlled conditions can lead to fewer failed prints, which can be encouraging for newcomers.

Experienced users often appreciate the customizability of open printers. However, professionals who require consistent, high-quality outputs might prefer the advanced features and stability of enclosed models.

2. Print Quality and Material Versatility

If you're primarily working with basic materials like PLA, an open printer can serve you well. These printers are often sufficient for hobby-level projects and basic prototyping.

For those needing to print with more demanding materials such as ABS or nylon, or requiring consistently high-quality prints, an enclosed printer often proves superior. The controlled environment helps maintain optimal printing conditions, resulting in better print quality and expanding your material options.

3. Environmental Considerations

When considering your printing environment, think about noise levels, odors, and available space. Open printers can be noisier and may emit odors, which might be problematic in shared or small spaces. If you have a dedicated, well-ventilated area, this might not be an issue.

Enclosed printers offer better noise and odor control, making them more suitable for home offices or shared workspaces. They also provide a cleaner, more professional appearance, which might be important in certain settings.

4. Budget and Long-term Costs

Open printers generally have a lower upfront cost, making them attractive for hobbyists or those new to 3D printing. If you're working with a tight budget, this might be the deciding factor.

While enclosed printers are pricier initially, they may save money over time through more efficient material use and fewer failed prints. Consider both the immediate and long-term financial implications when making your choice.

5. Safety and Health

If you're concerned about exposure to fumes or have children or pets around, an enclosed printer offers better safety features and fume containment. This can be a crucial factor, especially in home or educational environments.

Your choice between an open or enclosed 3D printer should align with your specific goals, working environment, and the types of projects you plan to undertake. Consider your priorities carefully to make the choice that best suits your 3D printing journey.

Find Your Ideal 3D Printer

As we've explored, both open and enclosed 3D printers have their strengths. Your ideal choice depends on your specific needs, budget, and environment. Open printers offer accessibility and lower costs, making them great for hobbyists and learners. Enclosed printers provide better print quality, material versatility, and safety features, suiting professionals and those working with advanced materials. Consider your skill level, desired print quality, workspace, budget, and safety requirements when making your decision. Remember, there's no universally "best" option – only the printer that's right for you. With this knowledge in hand, you're now equipped to make an informed decision. Take the next step and start comparing 3D printer models today.