Guide to 3D Printing With Nylon

Table of Contents

Nylon filament enables durable 3D printed parts thanks to strength, flexibility, heat, and impact resistance exceeding traditional plastics. However, leveraging these properties poses specific requirements - from printer upgrades to proper storage and processing. Getting these factors right unlocks a versatile thermoplastic allowing advanced users to produce functional prototypes, robot components, and end-use parts rivaling injection molding quality. This guide covers properties, applications, preparation, optimal print settings, and troubleshooting tips for successfully printing with nylon.

What is Nylon for 3D Printing?

Nylon refers to a family of rugged polyamide-based thermoplastic materials well-suited for printing durable parts able to withstand mechanical stresses over time. Nylon has higher strength, heat resistance, and flexibility compared to widely used 3D printing plastics like ABS and PLA.

There are two main types of nylon filaments:

- Nylon 6 (Polyamide 6 or PA6): The most popular option, made from a 6-carbon atom chain polymerized with amino acids. Known for affordability and ability to strike a balanced set of mechanical properties.

- Nylon 12 (Polyamide 12 or PA12): Offers even more flexibility and impact resistance thanks to its longer 12 carbon atom chains per polymer.

Nylon filaments can also be reinforced with other materials for enhanced properties:

- Carbon fiber reinforced nylon:Offers substantial increases in stiffness, rigidity, and tensile strength at the expense of more brittle behavior.

- Glass fiber reinforced nylon:Also boosts strength markedly while retaining more of pure nylon's native ductility and flexural characteristics.

Key Properties of Nylon for 3D Printing

Nylon stands apart from conventional 3D printing plastics thanks to:

- Superior durability: Excellent tensile strength and elongation resistance for withstanding mechanical wear and tear over time without cracking or deforming.

- Inherent flexibility: Elasticity is great for snap-fit parts, sturdy living hinges, and impact resilience.

- Thermal endurance: Withstands hot temperatures exceeding 180°C, allowing tests of part prototypes under realistic operative conditions.

- Moisture responsiveness: Standard nylons absorb humidity quickly, but specialized nylons like Qidi UltraPA have a significantly lower moisture absorption rate, enhancing their dimensional stability and mechanical properties.

- Chemical resistance: Has moderate resistance to oils, greases, solvents, and alkalis for reliability in various real-world environments.

- Strongest layer bonding performance: Qidi UltraPA exhibits enhanced layer adhesion, resulting in stronger printed parts compared to those made with traditional materials like ABS and PLA.

The balanced combination of strength, flexibility, and thermal/chemical handling make nylon a versatile material choice when aiming for resilient functional parts able to endure stress and impacts in real-world applications.

Common Applications of Nylon in 3D Printing

Nylon's balanced material properties make it one of the most versatile plastics for 3D printing real-world functional components across industries.

- Engineering prototypes and concept models- Nylon allows prototypes to be tested in realistic environments, undergoing expected loads, impacts, or thermal conditions without premature breakage. This provides confidence in the design before investing in metal molds.

- Low-volume end-use production parts - For non-critical components like pulleys, gears, and handles, nylon offers injection molding-like durability while avoiding high mold costs. Resistance to fatigue and wear makes it ideal for components seeing constant motion and friction.

- Robotics components- The flexibility of nylon allows printed robot parts like chassis, arms, and mounts to reliably withstand crashes and collisions during development. This facilitates rapid design iteration.

- Automotive interior and non-critical parts- Excellent heat aging resistance suits nylon for replacements of components like interior trim pieces, ducts, and ventilation system parts that must hold up well against sun exposure over years of service.

From early prototyping through to end-use components, nylon empowers iterative design while also enabling production use when strength plus environmental resilience is valued over absolute precision.

How to Prepare to Print with Nylon

Properly preparing nylon filament, the print bed surface and your printer will determine success versus headaches when printing. Key steps include:

1. Storing Nylon Filament

As nylon polymer readily absorbs moisture from the air over time, unused filament should be stored with care to prevent premature degradation:

- Seal spools in airtight bags or bins with plenty of desiccant packs to actively absorb humidity

- For long-term storage spanning months, vacuum seal bags are the most reliable protection method

- If the filament is exposed to air, use it quicker rather than saving spools with unknown history

- Consider using commercial filament dryer boxes such as the Qidi filament dryer box, which not only provides comprehensive dust-proof and moisture-proof sealing to maintain filament dryness and extend lifespan but is also compatible with most 3D printing filament brands available on the market.

2. Drying Filament Before Printing

Filament that has absorbed ambient moisture causes myriad print defects from oozing/stringing to cosmetic issues and severely weakened mechanical properties. Effective drying methods before printing include:

- Oven drying on a spool holder at 50-60°C for 4-8 hours based on nylon type

- Allow the filament to cool back down completely before loading into your printer to prevent jams

3. Printer Modifications

To properly handle nylon's thermal needs and prevent part warping, some printer adjustments are advised:

- Install an all-metal hotend able to reliably heat to 260-280°C nozzle temperatures for clean extrusion

- Upgrade to a heated print bed between 60-100°C to support first-layer adhesion

- Construct an insulated enclosure around the print area to maintain chamber temperatures with less airflow disruption

Combining a heated bed plus chamber with additional surface preparations like glues or slurries enables excellent first layer sticking to print on.

Nylon Print Settings

Properly configuring print settings is crucial to leverage nylon's material properties into strong, functional printed parts. The following recommendations provide quality and reliability-focused guidelines.

1. Nozzle & Bed Temperatures

- Nozzle: 250-320°C prevents clogs and improves layer bonding. Optimal temp depends on print speed.

- Bed: 80-110°C supports adhesion. Standard nylons bond at the lower range. Additives require hotter temps nearing 100°C.

2. Print Speed

- Reduce travel speed to 40-60 mm/s for best accuracy and appearance. Faster cooling can induce warps.

- Slower print speeds of around 40 mm/s significantly improve interlayer adhesion strength.

3. Layer Height

- 1-0.2mm for the highest resolution with standard nylons

- Carbon/glass reinforced blends can reliably print at 0.3mm layer heights.

4. Bed Adhesion Methods

Along with a heated bed, further aids can improve first-layer sticking:

- Lightly sanded PEI sheets work well for nylon sticking

- Diluted PVA/wood glue thinly painted onto the print surface

- ABS filament dissolved in acetone and then applied to the bed

5. Enclosure Temperature

- Maintain 60-65°C inside temperature for minimal cooling variation

- Use a thermocouple to actively monitor chamber temp

- Insulation panels prevent drastic air temperature fluctuations

6. Preventing Warps & Delamination

Gradual, consistent cooling is vital for minimizing defects:

- Allow the enclosure to slowly cool to room temperature before opening

- Avoid directing cooling fans onto the layers during initial passes

- Consider annealing in a temp oven after removing the print

Optimizing these print settings requires more attention than routine PLA or ABS jobs, however forms the basis to transform nylon's impressive strength and thermal behavior into durable components. When dialed in correctly, nylon offers a leap in printed part consistency and reliability well worth the increased setup effort.

Post-Processing Nylon Prints

While nylon prints impress immediately after printing, additional post-processing can enhance aesthetics, properties, and perceived quality. Employ these techniques as needed for your application.

1. Cooling and Removal from the Print Bed

Let prints cool to 60°C or below before removing. Caution is needed as residual heat can make parts more prone to cracking if handled roughly.

2. Support Removal

Clippers work to remove easier support structures. Dissolvable PVA supports also work effectively with nylon.

3. Sanding and Smoothing Surfaces

Nylon responds well to vapor smoothing or being sanded/polished for a glossy appearance rivaling injection molded parts.

4. Painting or Dyeing Nylon Prints

Without additives, nylons tend to take paint and dye well if properly washed and prepared first. Primers also increase paint adhesion.

5. Chemical Solvent Smoothing

Chemical baths in D-Limonene solution smooth the print surface nicely, however, nylon dissolves much slower than other materials like ABS, so longer exposure times are needed. Proper safety precautions are mandatory.

Post-processing provides another avenue for customizing nylon prints to achieve your ideal appearance and performance goals. Take advantage of nylon's malleability when it comes to finishing techniques.

Troubleshooting Common Issues with Nylon 3D Printing

Follow this advice to resolve common nylon printing challenges:

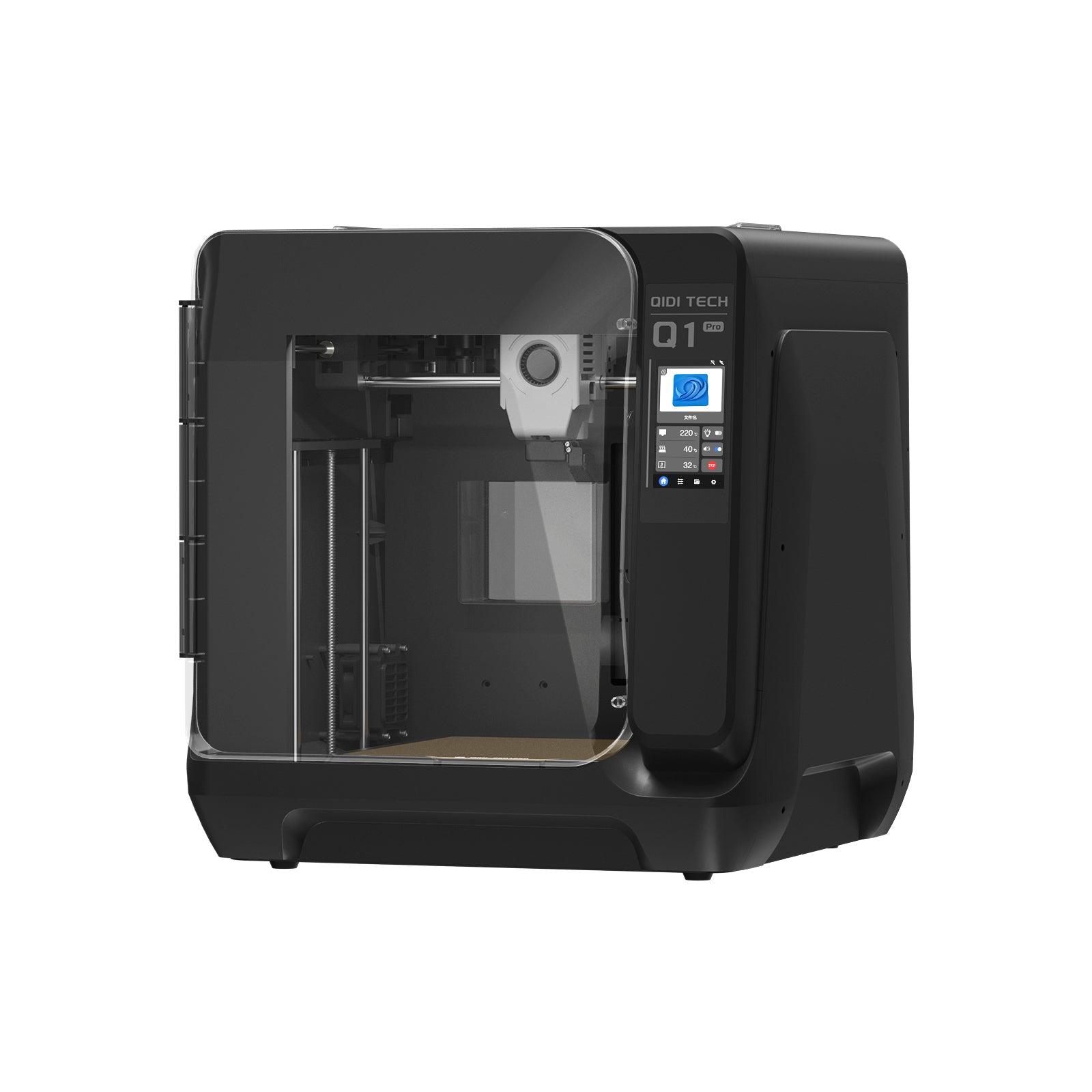

- Warping & Bed Adhesion Failures: Increase heated bed temperature, slow down the print speed, and try additional adhesion helpers like glues or slurries. Enclose the printer to prevent cooling drafts. Additionally, to specifically tackle the issue of warping, many advanced 3D printer brands like QIDI TECH have adopted active chamber heating systems.

- Oozing & Stringing: Lower retraction distances to 4-6mm and minimum layer times to 10-15 seconds to counteract oozing issues. Check filament is thoroughly dry.

- Moisture-Related Problems: Re-dry filament and store sealed with desiccant when not printing. Use a filament dryer if ambient humidity is constantly high. Consider a more moisture-resistant filament blend.

- Temperature Fluctuations: PID tune hotends after upgrades. Verify thermocouples firmly contact hotends. Improve enclosure insulation if temperatures shift.

- Mechanical Failures: Increase infill density or use a carbon/glass-reinforced nylon composite for added strength. Optimize part orientation on the bed to distribute forces smarter.

Follow all relevant usage guidelines including ventilation requirements and waste handling procedures.

Final Thoughts

Nylon's impressive strength, flexibility, heat resistance, and surface finish enable 3D printing of durable real-world parts rivaling injection molding. However, moisture control, printer upgrades, tuned print settings, and post-processing techniques are prerequisites to leverage these benefits. When meticulous protocols are followed, users across industries can tap nylon's potential for long-lasting functional prototypes, robotics components, and end-use production pieces seeing mechanical wear. As material formulations and printer capabilities advance further, nylon's accessibility and impact will continue rising across manufacturing.