How to Store 3D Printer Filament Properly

Table of Contents

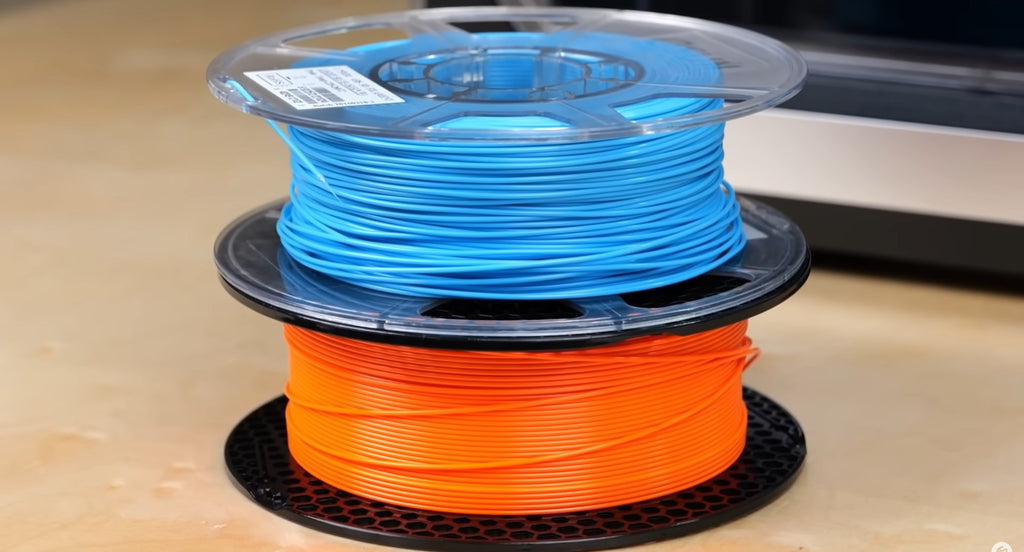

3D printing allows rapid prototyping and the creation of custom objects on demand. But the quality of your printed parts depends greatly on properly storing the plastic filament feedstock. When exposed to dust or moisture, the filament becomes brittle and stringy, wreaking havoc on print results. Implementing the right filament storage strategies is critical to consistent print performance and end-product quality over time.

Why Proper Filament Storage Matters

Keeping your 3D printing filament dry through proper storage is critically important for real-world results. Here's why:

- Prevent wasted filament from breakage- Wet filament gets brittle and snaps inside the extruder, ruining the spool.

- Avoid failed prints from nozzle clogs- Moisture creates bubbles that clog nozzles mid-print, wasting time and filament.

- Maintain vivid colors and clarity- Exposure to humidity causes fading and discoloration over time.

- Enable smooth extrusion without popping- Moisture turns to expand steam, preventing clean extrusion.

- Stop layer separation and adhesion issues - Water particles prevent layers from fusing properly during printing.

- Eliminate stringing and oozing- Wet filament extrudes inconsistently, increasing unwanted stringing.

- Keep printer components safe- Popping filament can damage gears, sensors, and other printer parts over time.

Storing filament properly keeps your printer running smoothly, prevents wasted time and materials from ruined prints, and maintains the quality of finished prints. It's one easy way to improve your 3D printing experience dramatically.

How Different Filament Types Handle Moisture

Not all 3D printing filaments react the same when exposed to humidity. Some materials readily soak up and hold onto water, while others are more resistant. Knowing how prone each type is to moisture damage can help you customize storage appropriately.

- PLA is very vulnerable to moisture. Its chemistry makes PLA eager to absorb water from the air. Even small amounts of humidity can negatively affect printing. Keeping PLA completely sealed in airtight containers is key for maintaining dryness.

- Nylon is extremely thirsty for moisture. Its polymer structure soaks up and grips onto water easily. Take extra steps for nylon like vacuum sealing, desiccants, and drying before use.

- handles moisture better than PLA but can still be gradually damaged over time. Use desiccant packs and check humidity levels periodically to prevent slow moisture absorption.

- TPU is slightly more resistant than PLA thanks to its flexible chemistry. But long-term exposure to humidity can still create printing problems. TPU benefits from sealed airtight storage.

- ABS is one of the most moisture-resistant filaments, but can still degrade with enough humidity without proper storage.

- Composites like wood, metal, and carbon fiber absorb less moisture than the base plastic alone. But composites still need dry storage conditions.

No matter the material, filaments degrade faster in humid environments. Hygroscopic types like PLA, nylon, and PETG especially need diligent dry storage. Match your storage to each filament's unique moisture needs.

How to Store 3D Printer Filament Properly

Properly storing your 3D printing filament is crucial for keeping it in ideal printing condition. By actively controlling humidity exposure, you can prevent moisture absorption issues that compromise print quality.

1. Desiccants for Moisture Protection

- Desiccants like silica gel beads actively absorb humidity to prevent moisture damage to filaments.

- Some types change color when saturated so you know when to replace them.

- Use enough desiccant - 2-3 grams per cubic inch of storage container space.

- Consider buying desiccants in bulk for cost savings with refillable containers.

2. Storage Containers and Methods

- Reuse original packaging with fresh desiccants for a quick solution.

- Zippered plastic bags work well for partial spools and keep types separated.

- Label everything clearly with permanent marker - filament type, color, date.

- Plastic bins allow tidy bulk storage and make it easy to organize a collection.

- Vacuum sealers provide the ultimate moisture barrier but avoid fully flattening filament shape.

- Store in a cool, dry area away from sunlight and humidity sources like bathrooms.

- Use sealed containers with desiccants inside larger dry boxes for double protection.

- Limit filament exposure during loading by quickly transferring from storage to printer.

With some upfront planning, you can implement an effective filament storage system. The right containers, desiccants, and care will maintain optimal printing conditions.

Display vs. Protection: Storage Methods Explored

Proper storage is crucial to keep filament dry, but accessibility when printing is also important. You need a balance of protection and convenience.

1. Open Shelving

Open shelving allows full visibility and access to your filament collection. This enables easy browsing and selection.

However, open-air exposure risks subjecting filament to humidity, dust, sunlight, and temperature swings.

Customizable shelving units let you store vertically to prevent tangling and deformation. Consider glass doors.

2. Climate-Controlled Storage

For large filament collections, a fully climate-controlled "filament bunker" provides ideal storage conditions.

Dehumidifiers actively remove moisture from the air. Hygrometers monitor humidity levels inside the storage space.

The best approach depends on your needs. Balance display appeal and accessibility with sufficient protection from environmental factors that degrade filament over time. For small collections, sealed containers with desiccants can work well. For big collections, invest in climate control.

How to Dry Out Wet Filament

1. Identifying Wet Filament

- Look for a filament that has become oval-shaped or deformed rather than round.

- Faded, dull color or water droplet markings are also signs of moisture absorption.

- Poor extrusion, stringing, brittle prints, and nozzle clogs while printing indicates high moisture content.

2. Filament Drying Methods

- DIY dryers use lightbulbs or hair dryers for heat and computer fans for air circulation inside an insulated enclosure.

- Commercial dryers actively heat to a target temp while dehumidifying, with precise controls and progress monitoring.

- Consider upgrades like exhaust ventilation and thermostat controllers for more advanced DIY dryers.

3. Recommended Drying Times

- PLAs: 2-4 hours at 140-160°F

- Nylons: 4-6 hours at 150-180°F

- PETG/TPUs: 3-5 hours at 135-155°F

- ABS: 2-3 hours at 180-200°F

Don't exceed the maximum recommended temperatures for each material. When in doubt, take time to thoroughly dry the filament prior to critical print jobs. But proper ongoing storage is key to preventing frequent re-drying needs.

Don't Let Filament Degrade!

Properly storing filament avoids wasting money and time on damaged spools and ruined prints. Exposure to humidity critically impacts printing performance through nozzle clogs, poor layer bonding, and stringing. Simple steps like sealed containers, desiccants, climate control, quick printer loading, and occasional drying maintain quality. Balance preservation from moisture, dust, and light alongside visible organization. With some diligence in introducing storage best practices suited to each material's unique needs, users safeguard consistent print success while easily accessing a collection. Printed part quality directly reflects filament integrity - so don't undermine great designs without properly implemented storage.