Is a Bigger 3D Printer Actually Better?

Table of Contents

As 3D printing technology continues advancing rapidly with ever more capable printers at affordable price points, an important question arises: When it comes to 3D printers, is bigger actually better? There is an active debate within the 3D printing community comparing the merits of large industrial-scale printers versus networks of multiple desktop machines. Both approaches have benefits depending on use cases and constraints.

This article will explore the key considerations around print size requirements, costs, reliability, workflow logistics, and business goals to help determine the ideal 3D printer size and number for specific needs. Whether going big with a few monumental machines or going wide across many compact printers, understanding these factors allows for properly tailoring 3D printing investments.

Range of 3D Printer Sizes

The 3D printer market encompasses a wide spectrum of sizes and capabilities. Build volumes can range from just a few cubic inches on consumer machines to multiple cubic meters on industrial printers.

1. Small Consumer 3D Printers:

- Priced under $500

- Build volumes under 250 cubic inches

- Allow educators, hobbyists, and entrepreneurs to explore 3D printing technology

- Limited in print scale and capability

2. Desktop Prosumer 3D Printers:

- Priced $2,000 - $5,000

- Build volumes of 1-2 cubic feet

- Able to produce moderately sized prints

- Offer greater reliability for professional use cases

3. Industrial Grade 3D Printers:

- Priced over $100,000

- Build volumes of multiple cubic meters

- Enable truly large-scale prints of sizeable objects in one piece

- Higher costs and space requirements but unconstrained printing capacity

The 3D printer market ranges from affordable small machines for personal use to expansive industrial printers for maximum production scale. Mid-range desktop models balance capability, reliability, and accessible pricing for professional users.

Advantages of Large-Format 3D Printing

For those whose needs demand it, investing in full-scale industrial 3D printers has compelling benefits:

- Single Piece Prints– The ability to produce a complete object, including large or elongated dimensions that would not fit on smaller machines. This avoids the need to print in sections and assemble them.

- No Size Constraints– With a meter-sized build platform, anything that fits within the print volume can be produced regardless of shape or scale. No limits to creativity.

- Batch Efficiencies – Large printers allow multiple identical items to be printed in one batch, amplifying productivity for medium to high-volume needs.

- Scalability– Starting with a sizable 3D printer leaves room to grow into bigger and bolder applications as experience is gained.

Clearly, when your requirements call for size, industrial printers enable printing freedom and volume unachievable through smaller setups. But bigger machines aren't always necessarily better across the board.

The Argument for Multiple Smaller Printers

Depending on specific use cases, spreading investment across several desktop 3D printers offers advantages:

- Flexibility and Redundancy– When one printer goes down for maintenance, the others keep operating, reducing downtime. Different jobs can also run in parallel rather than waiting in a print queue.

- Risk Management– If a large 30-hour print fails toward the end due to errors, you lose days of time and materials. With smaller printers, a failure only ruins a few hours of work.

- Lower Cost– Multiple desktop printers represent less upfront capital than one huge machine. Ongoing costs for repairs or upgrades are also minimized across smaller machines.

For applications that don't require oversized prints, spreading resources across a distributed network of smaller printers maximizes production uptime and minimizes losses from isolated issues.

What Is the Best Size for a 3D Printer?

The ideal 3D printer size depends on carefully evaluating your specific use cases, requirements, and constraints. There is no universally "best" size, but rather the optimum choice balances capabilities against realistic needs.

Key factors to consider when selecting the right 3D printer size include:

- Assess the need for oversized prints - Consider the frequency of projects requiring very large build volumes only achievable on industrial printers. Balance expanded capability against costs if rarely utilized.

- Understand object types- Small intricate objects have different ideal print volumes than large furniture or full prosthetics. Match printer size to typical object sizes.

- Compare speed versus quality- Industrial printers are slower but offer exceptional quality, while desktops sacrifice some precision for speed. Prioritize what matters most.

- Evaluate reliability- Larger machines generally have higher reliability once calibrated, while smaller printers can suffer more frequent maintenance disrupting production.

- Perform cost-benefit analysis- A single large printer may be more efficient depending on usage rates, as unused capacity on smaller printers wastes money. But incremental expansion may make economic sense.

- Consider space constraints- Footprints of industrial printers can be substantial. Ensure adequate space, power, ventilation, and noise reduction.

Carefully weighing all the variables of your specific use case will reveal the optimum 3D printer size, balancing capability against realistic requirements. Avoid overspending on unnecessary capacity while considering potential future growth needs.

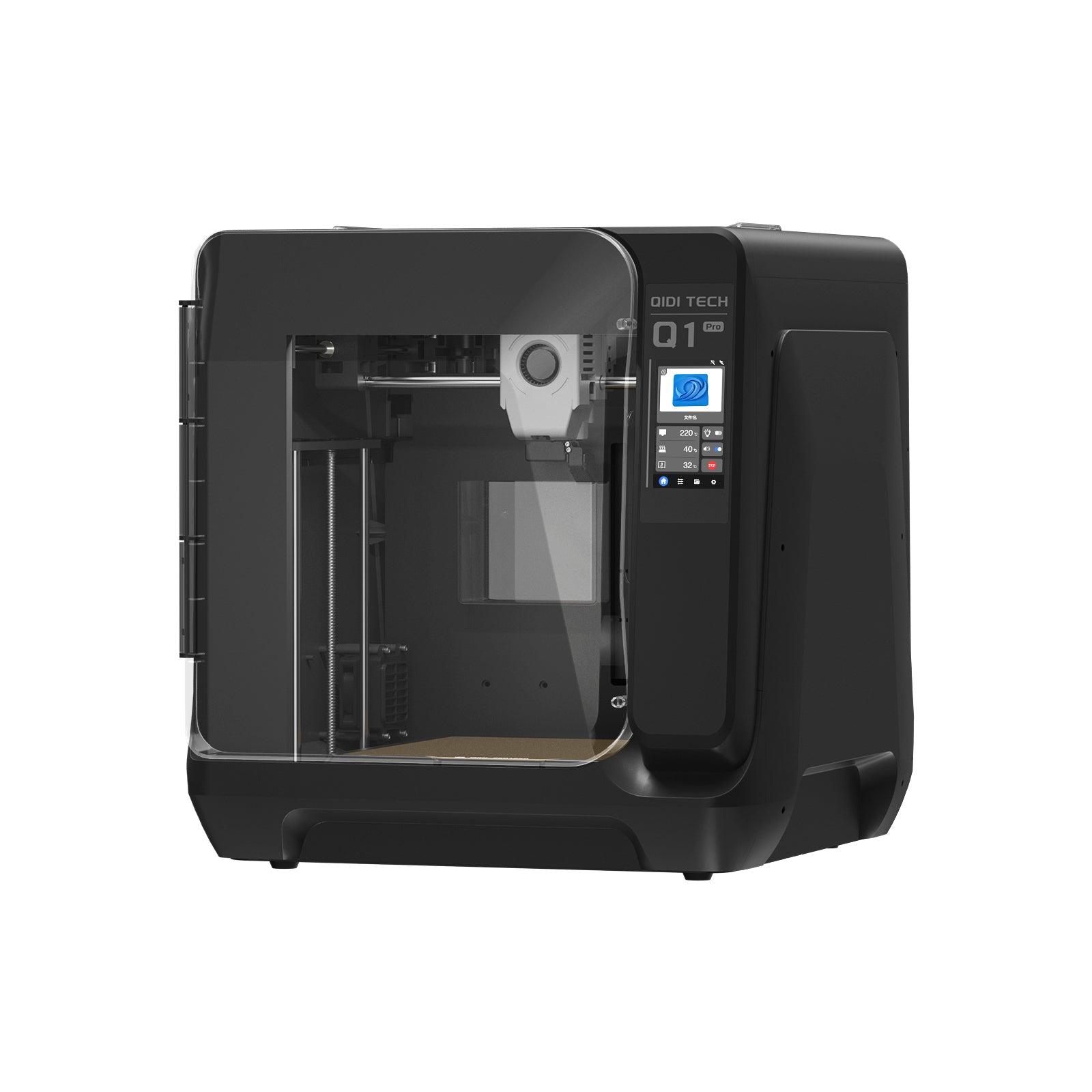

Why You Should Choose X-MAX 3 From QIDI Tech?

For those seeking industrial-scale production capabilities in an affordable package, the X-MAX 3 rises above competitors through innovative features optimizing print quality, speed, reliability, and ease of use.

Massive Build Volume

-

The spacious 325x325x315mm build chamber comfortably produces large single-piece prints useful for furniture, prosthetics, concept vehicles, and architecture.

- Schools and small firms gain future-ready capacity far exceeding typical desktop printers.

Lightning-Fast Print Speeds

- Innovations like the all-metal frame, CoreXY gantry, and hardened steel rails enable swift print speeds up to 600mm/s with precision.

- The streamlined system reduces motion inertia for blazing throughput.

Adaptable Single Extruder

The single print head accepts interchangeable hardened steel and copper nozzle tips, adapting the X-MAX 3 to a wide range of filament materials with temperatures reaching 350°C. This flexible hotend design supports printing with two different filament types.

Reliability and Consistency

- The integrated heated chamber up to 65°C and a drying box optimizes printing tricky filaments like PETG and Nylon by preventing warping and layer separation.

- Automatic bed leveling and mesh bed compensation ensure flawless first layers and consistent quality across the oversized build plate.

Breakthrough Affordability

- At the incredible low price of $899, the X-MAX 3 delivers all the industrial scale, speed, and reliability of systems.

- This unbelievable value makes enterprise-level output accessible to small businesses, schools, startups, and hobbyists.

With its optimized blend of leading-edge innovations for high speed, reliability, and huge build volume, the QIDI X-MAX 3 empowers small businesses to achieve production-level output comparable to far more expensive industrial systems.

Final Thoughts

The ideal 3D printer size depends on your specific use case, balancing build volume, print quality, batch production needs, budget, and workflow constraints. For oversized single-piece objects, industrial printers excel, but modest use cases may be better served by flexible desktop printers. Innovative systems like the QIDI Tech's X-MAX 3 deliver industrial-grade production scale in a surprisingly affordable package, combining the best of both approaches. As 3D printing advances, scalable printing infrastructure lays the foundation to fully leverage this technology towards virtually any application imaginable. Investing in a printer tailored for current and future needs unlocks new potential.