Supercharge Your Creativity with Our 3D Printers for Sale

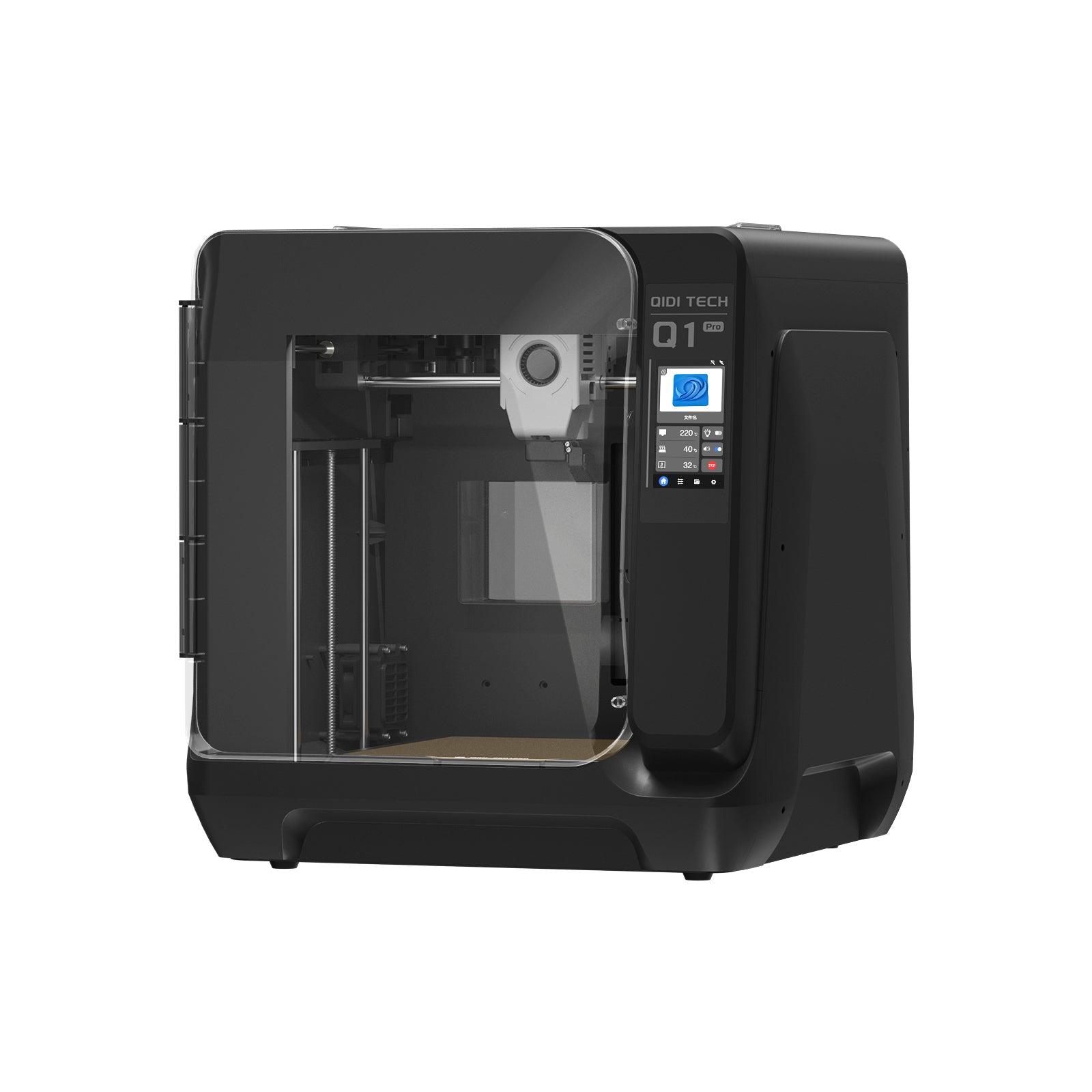

Unleash the power of 3D printing with QIDI Tech’s line of FDM 3D printers. Our product range includes the award-winning QIDI Tech X-Max 3, Q1 Pro and now the innovative QIDI Plus4 3D printer, each engineered for speed and precision. Use our reliable consumer-grade 3D printers to transform your ideas into complex models that will pave your way in a variety of industries.

We promise to deliver outstanding value without sacrificing performance, offering comprehensive 3D printing solutions that combine quality and price. Each of our Qidi 3D printers is carefully built to satisfy hobbyists, beginners, and more professional professionals. For beginners, our machines offer a gentle learning curve, with a user-friendly interface and fail-safe features, ensuring your first foray into 3D printing is both enjoyable and rewarding. Hobbyists will be delighted by the enhanced features that allow for more complex and larger-scale projects while maintaining an economical price point. For advanced users, our printers offer robust build quality, advanced thermal controls, and high-speed printing without compromising the meticulous detail required for professional applications.

The newly launched QIDI Plus4 3D printer: Fully automatic calibration can automatically detect and adjust the horizontal position of the print bed to ensure that the distance between the print bed and the extrusion head is equal everywhere before printing starts. It is easy to use and can significantly improve the adhesion and adhesion of the printed object. Precision of the final product.

No matter your experience level, whether you're a seasoned hobbyist or new to the world of 3D printing, you can take advantage of our user-friendly and affordable 3D printers. QIDI 3D printers offer the perfect blend of speed, precision and reliability to make 3D printing dreams come true.

What are you waiting for? Unleash your creative potential and start your 3D printing journey with QIDI today. Enter the exciting world of 3D printing - buy now at the best prices!

FAQs about FDM 3D Printer

An FDM 3D printer, also known as Fused Deposition Modeling printers, is a printer that creates objects through layer-by-layer deposition of molten plastic filament. The plastic filament is heated until it becomes molten and extruded through a nozzle to form the shape of interest. One reason FDM printers are popular is that they are inexpensive and very easy to use, so they are widely used by both beginners and professional users.

FDM 3D printers have several advantages. The first one is that they are usually more cost-effective than other types of 3D printing technologies. This economy makes them accessible to a wide market, such as hobbyists, educators, and professionals. Second, FDM printers are user-friendly and accommodate a wide range of materials, from tough to engineering-grade thermoplastics, such as ABS and PLA. These printers are versatile, which enables one to use them in a wide range of applications, from prototyping to designing functional parts. The parts produced are strong, and they can withstand mechanical use. Running costs are also low, as it does not require any type of hazardous chemicals, making it safe and easy to run.

The FDM 3D printing process involves designing a 3D model using CAD software. After your design is ready, slicing software is used to convert the model into various layers. The printer then heats the plastic filament and extrudes it through a nozzle, laying down each layer according to the sliced model. As the layer is laid down, it cools and solidifies, building up the final object. This layer-by-layer mechanism provides control over the final object's shape and structure.

SLA and FDM are two different 3D printing technologies. The main difference is the material and the process. FDM printers use thermoplastic filaments, which are melted and extruded to lay down layers. SLA printers use liquid resin that is cured by a laser to cure each layer. SLA is usually at a better resolution, and the surfaces are smoother, so it's very fit for the designs with much detail and very intricate. FDM is more suitable for functional prototypes and bigger parts because it's stronger and cheaper. Generally, FDM is also cheaper compared to SLA printers and their materials.

Print resolution, layer height, extruder and platform temperature, print speed, filament quality, nozzle size, and proper slicer settings all impact the final print quality. Dual extrusion, an enclosed build chamber, and auto-calibration features also help improve consistency, precision, and reliability.